Subcritical hydrolysis-based organic solid waste treatment system and treatment method utilizing same

An organic solids, treatment system technology, applied in biomass post-treatment, biomass pretreatment, biochemical equipment and methods, etc., can solve the problem of anaerobic digestion treatment unit covering a large area, low biogas production, long fermentation period, etc. problems, to achieve the effect of improving the availability, biogas yield and biogas methane purity, and shortening the fermentation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

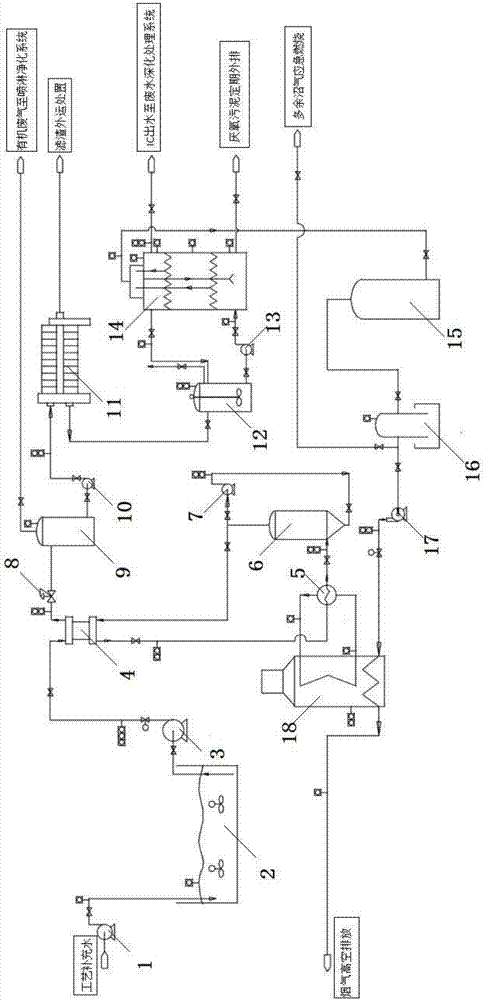

Method used

Image

Examples

Embodiment example 1

[0062] Discarded antibiotic residues from the chemical manufacturing industry: Antibiotic residues will be transferred and accumulated through the environment and the food chain because they contain residual pharmaceutical ingredients. Since 2008, the residues have been listed as hazardous waste by the state.

[0063] The present invention handles the process technology of antibiotic bacterium slag and the design ability index of equipment:

[0064] Process technology: Add antibiotic residues with a solid content of 30.5% to the homogenization tank according to the proportion of 6.1% solid content mixed solution to supplement the process water, stir 200-300r / min, stir 30min / cycle, and the homogenized material enters To hydrolyze in the subcritical hydrolysis system, set the temperature of the hydrolysis reactor to be controlled within the range of 150°C-200°C, and the pressure to be 1.0-1.2MPa to keep the homogenized material in a liquid state, and keep the temperature and pres...

Embodiment example 2

[0066] Residual sludge from biochemical treatment of municipal sewage:

[0067] Sludge is solid waste generated during sewage treatment, and its main components are pathogens, organic matter, bacteria, etc.

[0068] The present invention handles the process technology of sludge and the design ability index of equipment:

[0069]Process technology: The moisture content of the sludge dewatered by the belt filter press in the sewage plant is below 80%, and it is transported to the homogenization tank, and the mixed solution of the effluent of the secondary sedimentation tank is extracted by the submersible sewage pump, and adjusted according to a certain ratio to a moisture content of ≤ 93-95%; the sludge with a water content of 94% is transported by a plunger pump, first passes through the primary heat exchanger to exchange heat with the discharge of the hydrolysis reactor, and then passes through the secondary heat exchanger to exchange heat with the heat transfer oil, and fina...

Embodiment example 3

[0072] Municipal food waste:

[0073] Food waste is organic solid and liquid waste formed by residents in the process of living consumption, including urban vegetable waste, restaurant food waste, household kitchen and dining table waste, and various melon and fruit peels. Statistics from the Institute of Solid Waste Pollution Control and Recycling, Department of Environment, Tsinghua University show that cities in my country generate no less than 60 million tons of kitchen waste every year. The main characteristics of food waste are high moisture content, rich organic matter content, and perishability. The percolation water will pollute water bodies and the atmosphere, and affect the urban appearance and living environment.

[0074] The design capability index of the process technology and equipment of the present invention for processing kitchen waste:

[0075] Process technology: First, the food waste is conveyed to the crushing equipment through the screw conveyor for cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com