Nickel-free chemical copper plating solution and preparation method thereof

A technology of electroless copper plating and solution, which is applied in the field of nickel-free electroless copper plating solution and preparation, can solve the technical difficulties of high-end high-frequency circuit board manufacturing, the physical properties of the plating layer need to be improved, and the health problems of environmental protection people, etc., and achieve good results. Good binding force and conductivity, good backlight effect, and the effect of maintaining physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

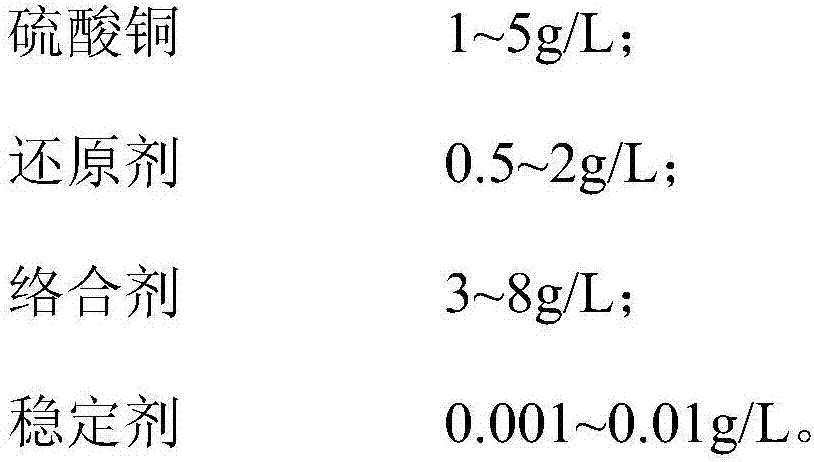

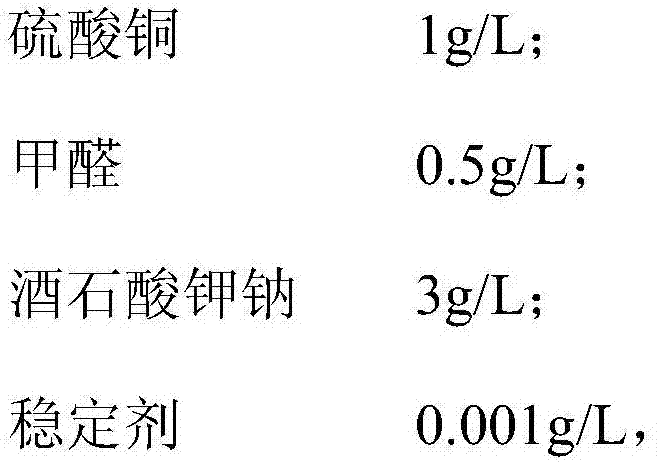

[0034] The nickel-free type electroless copper plating solution of the present embodiment is made up of following material by mass concentration:

[0035]

[0036] The stabilizer is composed of thiouracil with a mass concentration of 0.0005g / L, bipyridine with a mass concentration of 0.0001g / L and potassium tetracyanonickelate (II) potassium hydrate with a mass concentration of 0.001g / L and the balance The composition of deionized water;

[0037] The balance is deionized water.

[0038] The preparation method of the above-mentioned nickel-free type electroless copper plating solution is: according to the mass concentration, the copper sulfate of 1g / L, the formaldehyde of 0.5g / L, the potassium sodium tartrate of 3g / L, the stabilizer of 0.001g / L and the balance The deionized water was mixed evenly, and the pH was adjusted to 11 with sodium hydroxide to obtain the nickel-free electroless copper plating solution.

[0039] Take a 10cm×10cm circuit board base material after cle...

Embodiment 2

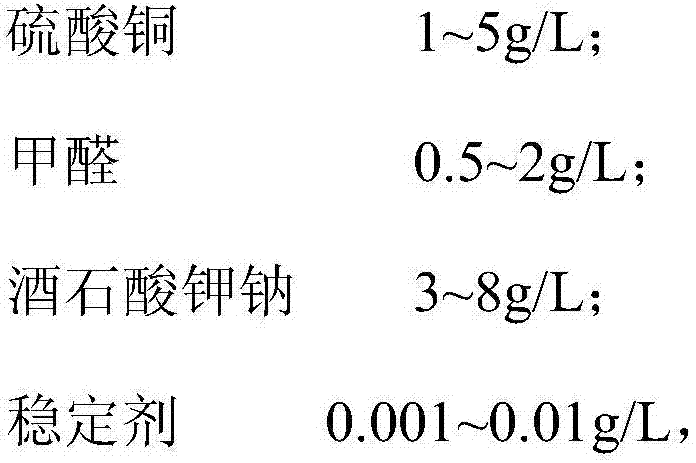

[0042] The nickel-free type electroless copper plating solution of the present embodiment is made up of following material by mass concentration:

[0043]

[0044] The stabilizer is composed of thiouracil with a mass concentration of 0.005g / L, bipyridine with a mass concentration of 0.0006g / L and potassium tetracyanonickelate (II) potassium hydrate with a mass concentration of 0.008g / L and the remainder The composition of deionized water;

[0045] The balance is deionized water.

[0046] The above-mentioned nickel-free type electroless copper plating solution preparation method is: according to the mass concentration, the mass concentration is copper sulfate of 5g / L, formaldehyde of 2g / L, potassium sodium tartrate of 8g / L, the stabilizing agent of 0.01g / L and The remaining amount of deionized water was mixed evenly, and the pH was adjusted to 11.5 with sodium hydroxide to obtain the nickel-free electroless copper plating solution.

[0047] Take a 10cm×10cm circuit board b...

Embodiment 3

[0050] The nickel-free type electroless copper plating solution of the present embodiment is made up of following material by mass concentration:

[0051]

[0052] The stabilizer is composed of thiouracil with a mass concentration of 0.001g / L, bipyridyl with a mass concentration of 0.0016g / L and potassium tetracyanonickelate (II) potassium hydrate with a mass concentration of 0.005g / L and the remainder The composition of deionized water;

[0053] The balance is deionized water.

[0054] The preparation method of the above-mentioned nickel-free type electroless copper plating solution is: according to the mass concentration, the copper sulfate of 3g / L, the formaldehyde of 1g / L, the potassium sodium tartrate of 4g / L, the stabilizer of 0.002g / L and the balance of The deionized water was mixed evenly, and the pH was adjusted to 12 with sodium hydroxide to obtain the nickel-free electroless copper plating solution.

[0055] Take a 10cm×10cm circuit board base material after cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com