Preparation method and application of foam transition metal phosphide carrying noble metal

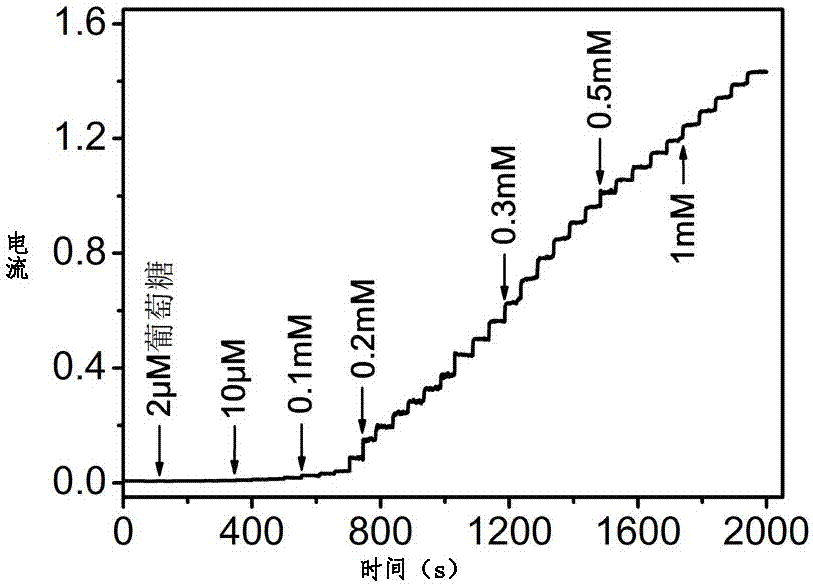

A transition metal and phosphide technology, which is applied in the field of electrocatalysis and electrochemical sensors, can solve the problems of few active sites and low electrocatalytic oxidation activity of glucose, and achieve enhanced catalytic activity, accelerated electron transfer rate, and increased specific surface area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

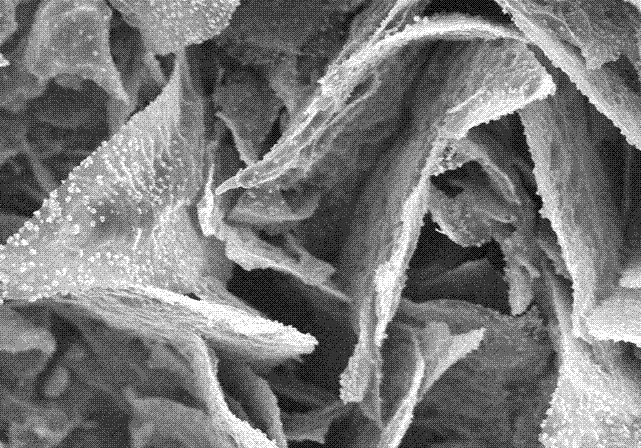

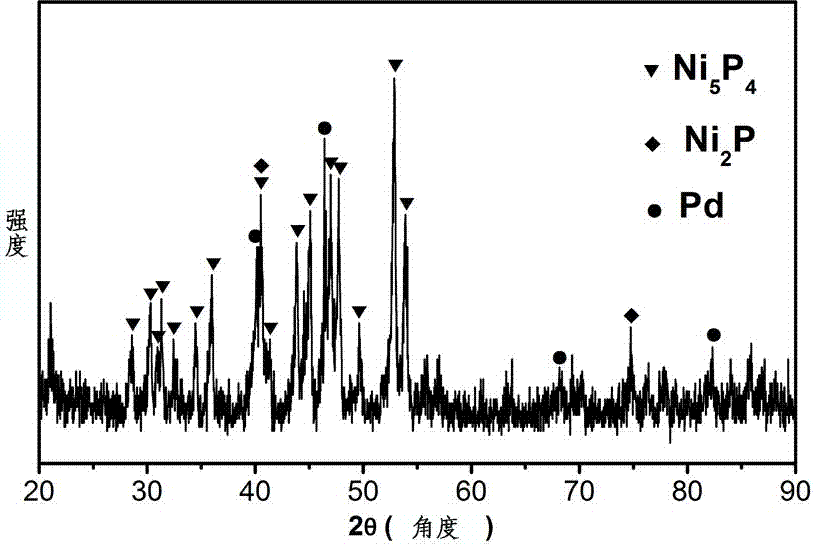

[0023] A preparation method for foamed nickel phosphide supported palladium, carried out according to the following steps:

[0024] Step 1. Soak the nickel foam in a hydrochloric acid solution with a mass fraction of 20%, and ultrasonically treat it for 10 minutes to remove the oxide layer on the surface, then use ultrapure water to wash it to neutral, and finally dry it for use; follow the protective gas (step In the airflow direction of the argon in the second), the red phosphorus powder and the foamed nickel whose surface has been removed from the oxide layer are respectively placed in the upstream area and the downstream area of the porcelain boat, and the mass ratio of the red phosphorus powder to the foamed nickel is 2:1;

[0025] Step 2. Place the porcelain boat prepared in step 1 in the center of the tube annealing furnace, feed argon gas as a protective atmosphere, and ventilate for 60 minutes to exhaust the air in the tube furnace cavity;

[0026] Step 3. Under the...

Embodiment 2

[0029] A preparation method for foamed copper phosphide loaded platinum, carried out according to the following steps:

[0030] Step 1. Soak the copper foam in a hydrochloric acid solution with a mass fraction of 10%, and ultrasonically treat it for 5 minutes to remove the oxide layer on the surface, then use ultrapure water to wash it to neutral, and finally dry it for later use; follow the airflow of the protective gas Direction, the red phosphorus powder and the foamed copper whose surface is removed from the oxide layer are respectively placed in the upstream area and the downstream area of the porcelain boat, and the mass ratio of the red phosphorus powder to the foamed copper is 1:1;

[0031] Step 2. Place the porcelain boat prepared in step 1 in the center of the tube annealing furnace, feed argon gas as a protective atmosphere, and ventilate for 30 minutes to exhaust the air in the tube furnace cavity;

[0032] Step 3. Under the protection of argon, first raise the t...

Embodiment 3

[0035] A preparation method for foamed iron phosphide loaded platinum, carried out according to the following steps:

[0036] Step 1. Soak the foam iron in a hydrochloric acid solution with a mass fraction of 5%, and ultrasonically treat it for 5 minutes to remove the oxide layer on the surface, then use ultrapure water to wash it until it is neutral, and finally dry it for later use, and follow the airflow of the protective gas Direction, the red phosphorus powder and the foamed iron whose surface is removed from the oxide layer are respectively placed in the upstream area and the downstream area of the porcelain boat, and the mass ratio of the red phosphorus powder to the foamed iron is 3:1;

[0037] Step 2. Place the porcelain boat prepared in step 1 in the center of the tube annealing furnace, feed nitrogen gas as a protective atmosphere, and ventilate for 60 minutes to exhaust the air in the tube furnace cavity;

[0038] Step 3. Under the protection of nitrogen, first r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com