A system and method for preparing high-purity vanadium pentoxide powder by chlorination

A vanadium pentoxide and chlorination technology, applied in the chemical and metallurgical fields, can solve the problems of different names, inability to directly apply to the reactor, and reducing the recovery rate of vanadium precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

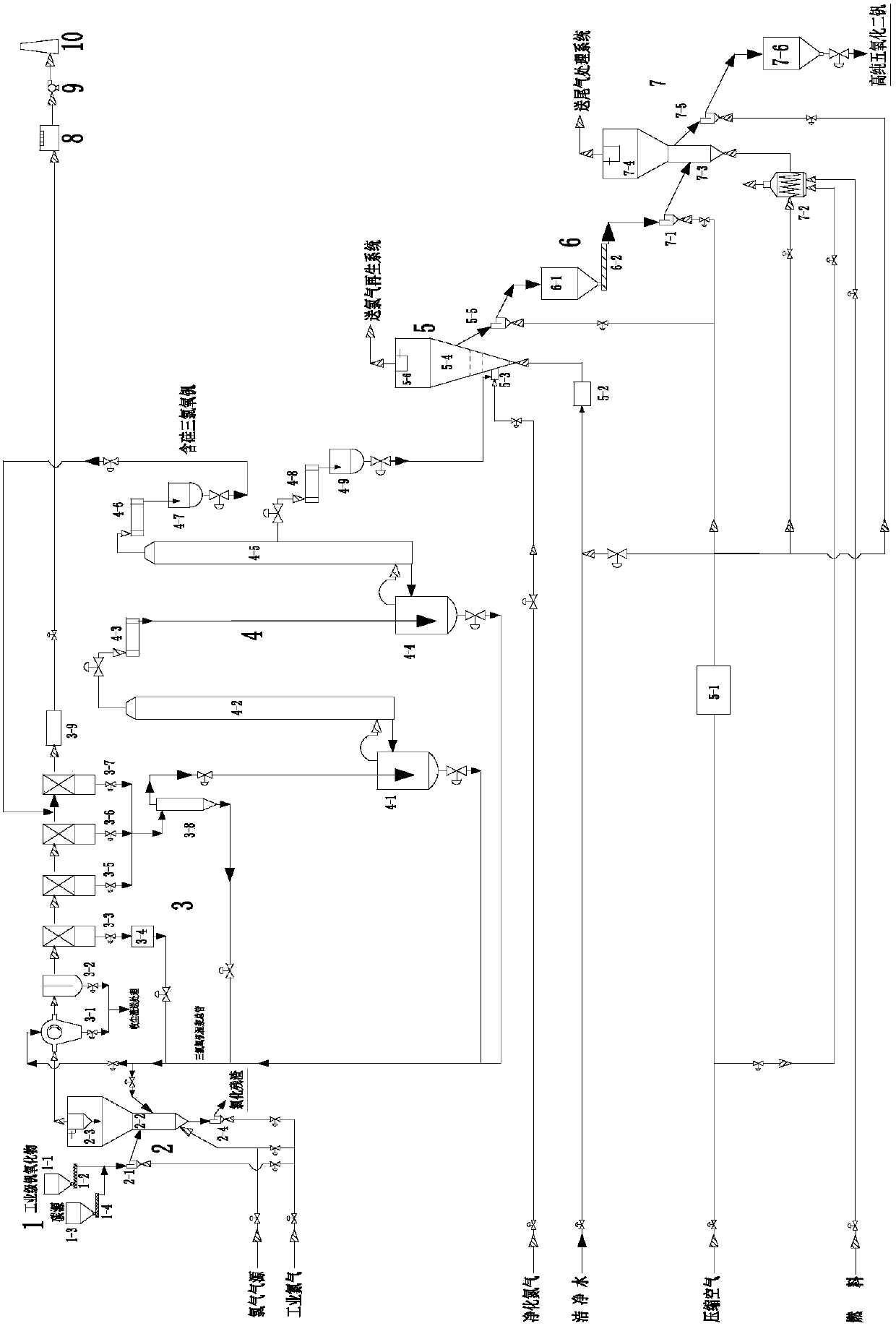

[0076] combine figure 1 , the system for preparing high-purity vanadium pentoxide powder by the chlorination method used in this embodiment includes a feeding section 1, a chlorination section 2, a dedusting and rinsing section 3, a rectifying purification section 4, a catalytic oxidation section 5, a catalytic Oxidation product feeding section 6, calcination section 7, tail gas washing absorption tower 8, induced draft fan 9 and chimney 10;

[0077] Among them, the feeding section 1 includes an industrial-grade vanadium oxide silo 1-1, an industrial-grade vanadium oxide screw feeder 1-2, a carbon source silo 1-3, and a carbon source screw feeder 1-4;

[0078] The chlorination section 2 includes a chlorination bed feeder 2-1, a chlorination fluidized bed main body 2-2, a chlorination bed cyclone separator 2-3 and a chlorination residue discharger 2-4;

[0079] Dust removal and washing section 3 includes primary dust removal device 3-1, secondary dust removal device 3-2, prima...

Embodiment 2

[0093] This embodiment provides the method for preparing high-purity vanadium pentoxide powder using the system described in embodiment 1, comprising the following steps:

[0094] The industrial-grade vanadium oxide in the industrial-grade vanadium oxide silo 1-1 and the carbon source in the carbon source silo 1-3 pass through the industrial-grade vanadium oxide screw feeder 1-2 and the carbon source screw feeder 1-4 respectively. Enter the chlorination fluidized bed main body 2-2 after entering the chlorination bed feeder 2-1 mixing simultaneously; From the chlorine of the chlorine gas source main pipe and the nitrogen of the nitrogen gas source main pipe through the chlorination fluidized bed main body 2-2 bottom The air inlet enters the main body 2-2 of the chlorinated fluidized bed to maintain the fluidization of the vanadium oxide and the carbon source and react with it, and the chlorine gas and the carbon source work together to chlorinate the vanadium oxide and a small a...

Embodiment 3

[0101] In this example, powdered industrial-grade vanadium pentoxide (purity: 98.50%) is used as raw material, and the processing capacity is 80 kg / h. It is prepared by chlorination, dedusting and washing, rectification and purification of vanadium oxychloride, catalytic oxidation and calcination. Obtain high-purity vanadium pentoxide product.

[0102] In the main body 2-2 of the chlorination fluidized bed, the amount of petroleum coke added during the chlorination process is 30% of the mass of the industrial-grade vanadium pentoxide powder, the operating temperature of the chlorination is 600°C, and the operating gas velocity of the fluidization section is 3.00m / s, the mole fraction of chlorine in the chlorine-nitrogen mixed gas entering the air chamber is 20%; in the main body 5-4 of the catalytic oxidation fluidized bed, the water vapor fed into the catalytic oxidation process is 30% of the quality of vanadyl trichloride, and the catalytic oxidation operation The temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com