Graphene/boron carbide ceramic composite material and preparation method thereof

A boron carbide ceramic and composite material technology is applied in the field of graphene/boron carbide ceramic composite materials and their preparation, which can solve the problem that graphene and ceramic substrates cannot form a contact interface, reduce the performance of graphene/ceramic composite materials, and destroy graphene. Microstructure and other problems, to achieve the effect of easy EDM, easy industrial enlargement, and avoid the phenomenon of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of graphene / boron carbide ceramic composite material, the method comprises the following steps:

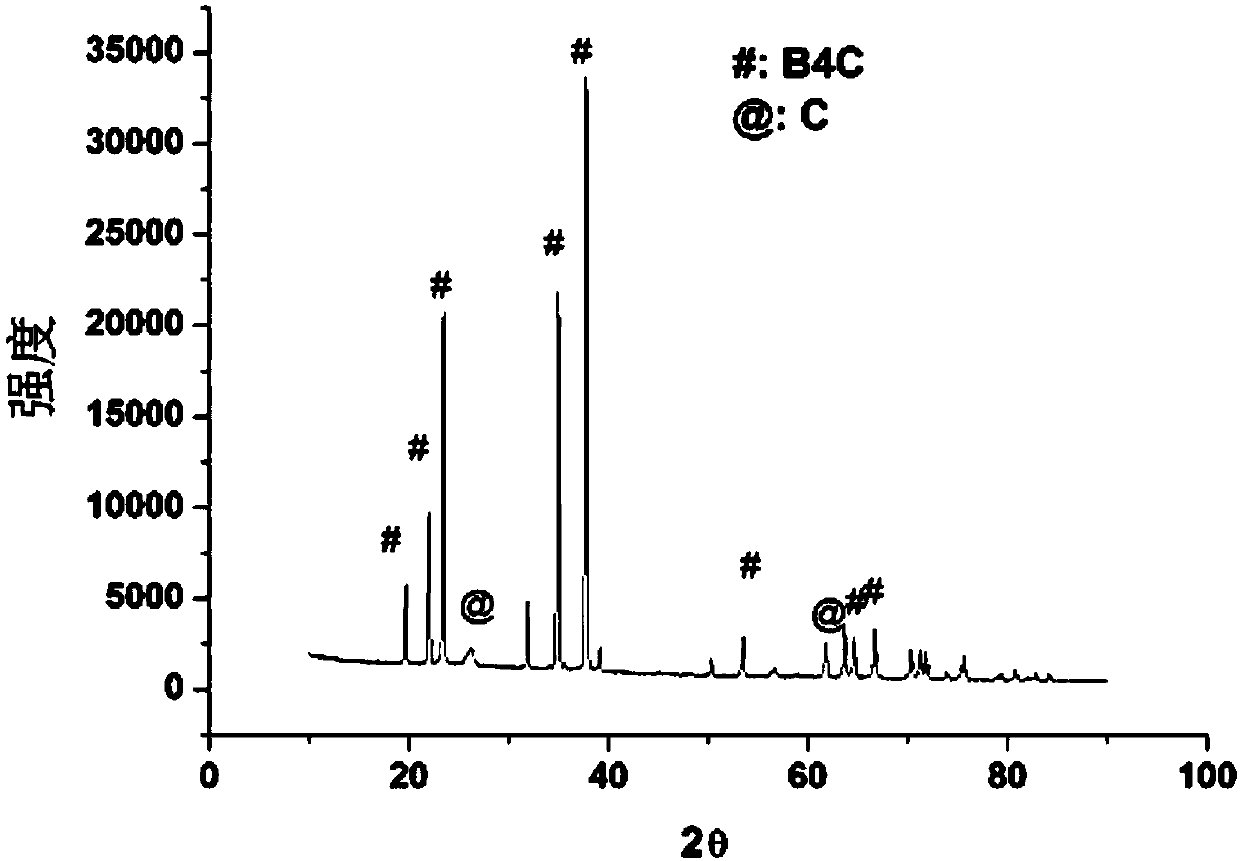

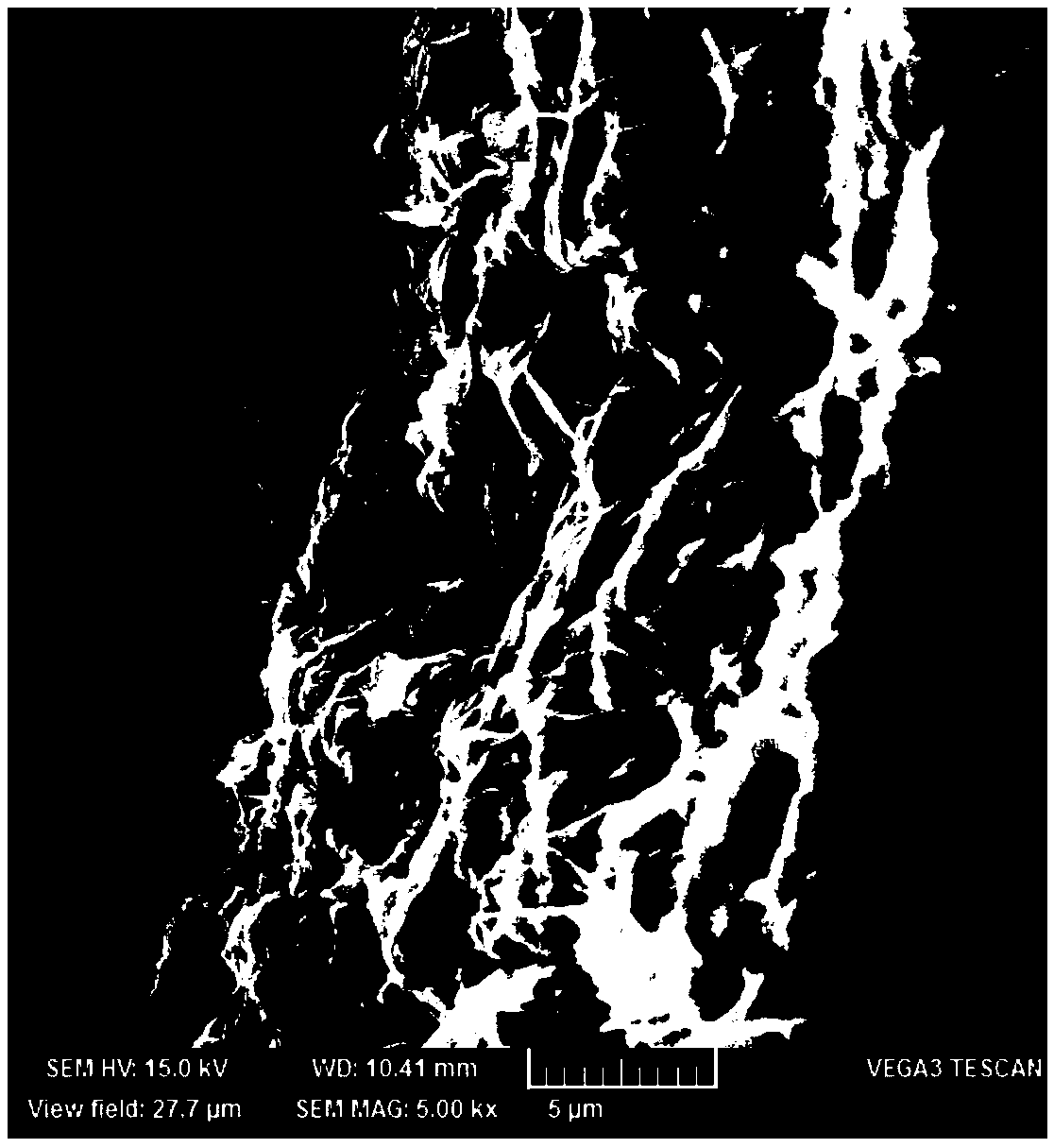

[0029] Step 1, adding graphene oxide, boron carbide and elemental silicon powder with a mass ratio of 10:85:5 to absolute ethanol, so that the mass of absolute ethanol accounts for 15% of the total mass, and graphite oxide is obtained after ultrasonic dispersion ene / boron carbide dispersion. After the graphene oxide / boron carbide dispersion is uniformly mixed by ball milling, spray granulation to obtain graphene oxide / boron carbide mixed powder;

[0030] Step 2: Place the graphene oxide / boron carbide mixed powder obtained in Step 1 in a graphite mold, heat up to 1950°C at a rate of 10°C / min, apply a pressing pressure of 100MPa to the powder, and keep it warm for 2 hours. With the cooling of the furnace, the whole sintering process is completed under the protective atmosphere of flowing argon, and the graphene / boron carbide ceramic composite material is...

Embodiment 2

[0035] A preparation method of graphene / boron carbide ceramic composite material, the method comprises the following steps:

[0036] Step 1, adding graphene oxide, boron carbide, elemental boron and amorphous carbon powder with a mass ratio of 8:85:3:4 to absolute ethanol so that the mass of absolute ethanol accounts for 20% of the total mass, After ultrasonic dispersion, a graphene oxide / boron carbide dispersion is obtained. After the graphene oxide / boron carbide dispersion is uniformly mixed by ball milling, spray granulation to obtain graphene oxide / boron carbide mixed powder;

[0037] Step 2: Place the graphene oxide / boron carbide mixed powder obtained in Step 1 in a graphite mold, heat up to 2000°C at a rate of 20°C / min, apply a pressing pressure of 80MPa to the powder, and keep it warm for 3 hours. With the cooling of the furnace, the whole sintering process is completed under the protective atmosphere of flowing argon, and the graphene / boron carbide ceramic composite m...

Embodiment 3

[0040] A kind of graphene / boron carbide ceramic composite material, its preparation method specifically comprises the following steps:

[0041] 1) respectively adding graphene oxide, boron carbide and sintering aid (silicon) into an organic solvent (absolute ethanol) in a mass ratio of 7:87:10, and mixing uniformly to obtain a graphene oxide / boron carbide dispersion;

[0042] 2) After the graphene oxide / boron carbide dispersion is mixed with a ball mill, spray granulation is carried out at a spray pressure of 0.07MPa, an inlet temperature of 120°C, and an outlet temperature of 75°C to obtain a graphene oxide / boron carbide mixture Powder, the particle size of the graphene oxide / boron carbide mixed powder is 45 μm;

[0043] 3) Put the graphene oxide / boron carbide mixed powder in the mold, and raise it from room temperature to 2000°C at a rate of 20°C / min under the protective atmosphere of flowing argon, and then hold it at a pressing pressure of 100MPa for 1.8h , complete the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com