Palladium nanoparticle supported layered double hydroxide nano-composite material, preparation method thereof, and ammonia borane catalytic decomposition method

A nanocomposite, double hydroxide technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, catalyst activation/preparation, etc. activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

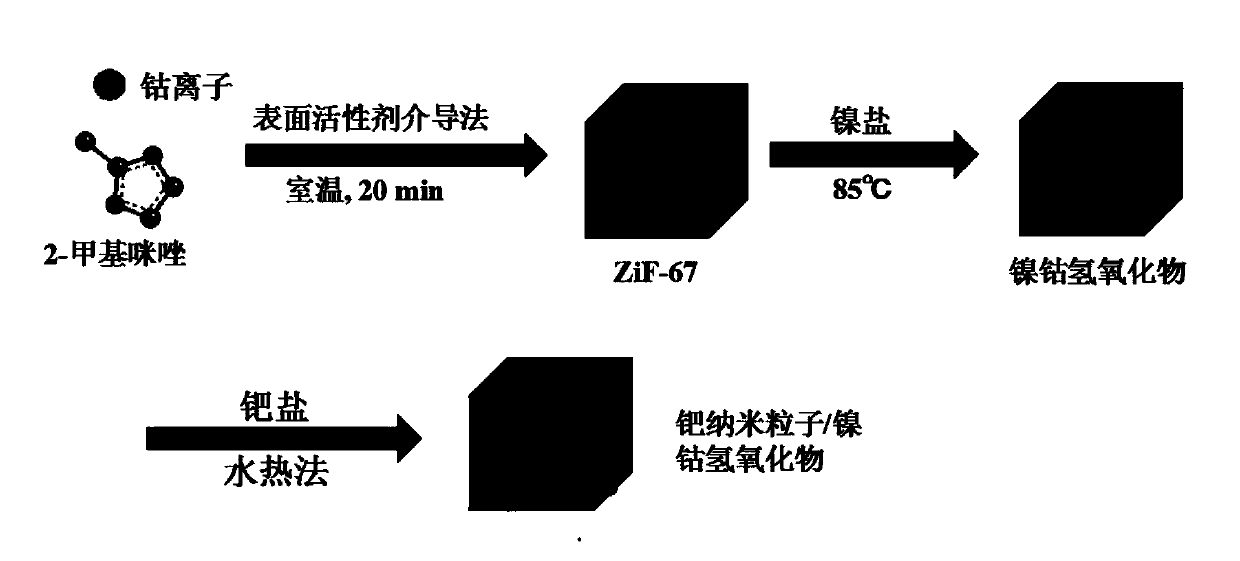

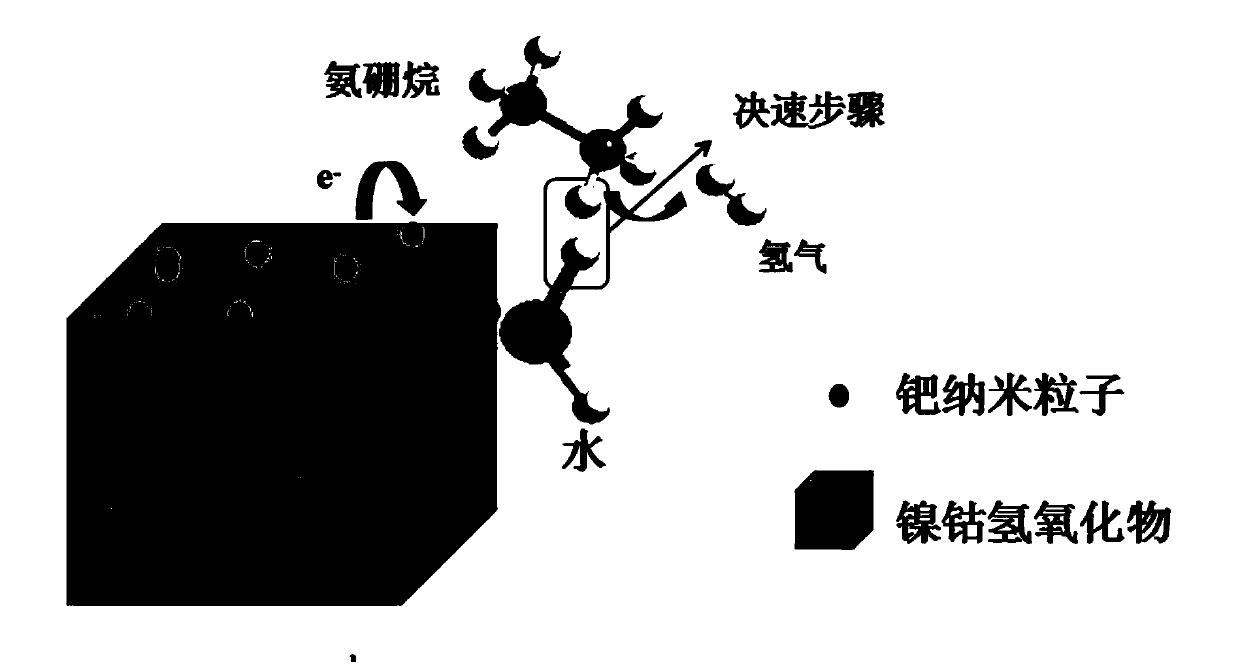

[0028] The invention provides a preparation method of a palladium nanoparticle-supported layered double hydroxide nanocomposite material, the preparation method comprising:

[0029] 1) Carrying out coordination polymerization reaction of cobalt source, 2-methylimidazole, surfactant and water to prepare coordination polymer ZIF-67;

[0030] 2) Contact reaction of coordination polymer ZIF-67 and nickel in an organic solvent to prepare NiCo LDH (nickel-cobalt layered double hydroxide);

[0031] 3) Disperse the palladium source and NiCo LDH in water, then adjust the pH of the system to 9.5-10.5, and then perform a hydrothermal reaction to prepare a nanocomposite material of palladium nanoparticle-loaded layered double hydroxide.

[0032] In step 1) of the above-mentioned preparation method, the consumption of each material can be selected in a wide range, but in order to make the nanocomposite material have more excellent catalytic properties, preferably, in step 1), relative to 1...

Embodiment 1

[0052] 1) Dissolve 908mg of 2-methylimidazole in 14mL of ultrapure water and stir for 10min, then quickly pour 2mL of aqueous solution (containing 1mg of CTAB and 58mg of cobalt nitrate) into the solution, continue stirring for 20min to obtain a purple suspension, and finally centrifuge with absolute ethanol and dried to obtain ZIF-67 purple powder.

[0053] 2) Disperse 30mg of ZIF-67 powder with 20mg of absolute ethanol, then weigh 100mg of nickel nitrate and add it and heat it under reflux at 85°C until the purple color of the system fades, centrifuge and dry to obtain NiCo LDH green powder.

[0054] 3) Disperse 20 mg of NiCo LDH powder with 5 mL of water to form a green suspension, add 5 mL of 0.1 mol / L sodium tetrachloropalladate aqueous solution, adjust the pH to 10 with 0.1 mol / L NaOH solution and stir for 30 min, transfer the mixed solution to Put in a 20mL polytetrafluoroethylene kettle and react at 100°C for 10h, cool to 25°C, and centrifugally dry to obtain 0.0025mol...

Embodiment 4

[0060] The Pd / LDH was prepared according to the method of Example 1, except that in step 3), the hydrothermal reaction met the following conditions: the reaction temperature was 150°C, and the reaction time was 4h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com