One-dimensional boron nitride nanomaterials and preparation method thereof

A technology of nanomaterials and boron nitride, which is applied in the direction of chemical instruments and methods, nanotechnology, nitrogen compounds, etc., can solve the problems of harsh conditions, dangerous conditions, only 40% output, high equipment requirements, etc., and achieve controllable appearance and high quality. Excellent, simple and controllable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] One aspect of the embodiments of the present invention provides a method for preparing a class of one-dimensional boron nitride nanomaterials, including: heating the one-dimensional borate precursor to 1000-1500°C in a nitrogen-containing atmosphere and keeping it warm for reaction, and then protecting The temperature is lowered to room temperature in the atmosphere to obtain a crude product, and then the crude product is post-treated to obtain a one-dimensional boron nitride nanomaterial.

[0021] Further, the one-dimensional borate precursor includes a one-dimensional borate material containing at least one element among lithium, beryllium, magnesium, calcium, strontium, barium, gallium, indium, zinc and titanium.

[0022] Further, the one-dimensional borate material may be selected from borate whiskers, borate nanorods, borate nanowires, borate nanoribbons, etc., and is not limited thereto.

[0023] More preferably, the preparation method includes: heating the one-di...

Embodiment 1

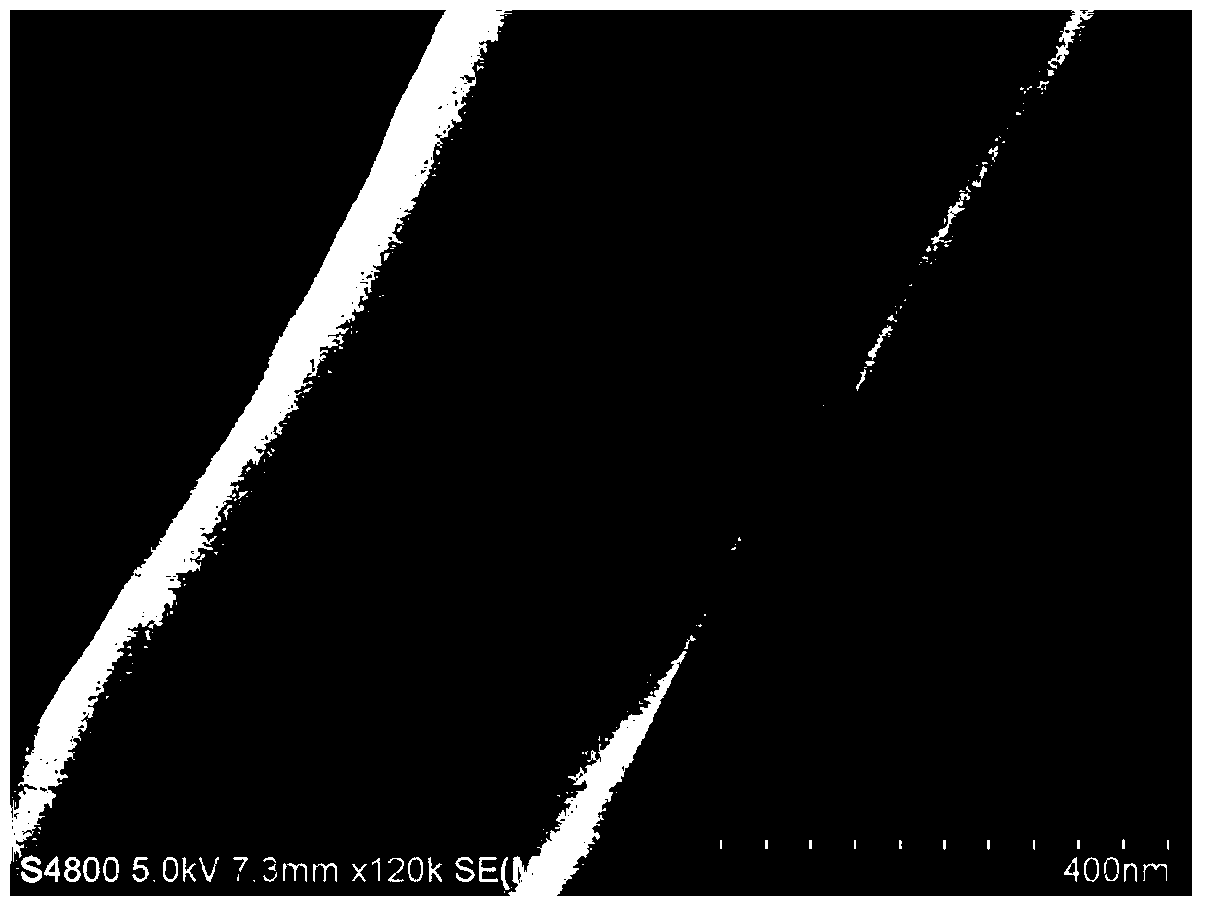

[0040] Example 1 takes a Mg with a diameter of about 50 nm and a length of about 10 μm 2 B 2 o 5 Whiskers 2g were filled in an open alumina crucible, then placed in a tube furnace, and vacuumed to 10 -3 Pa, 200 standard milliliters per minute (sccm) of NH 3 , heating up to 1300°C. Turn off NH after 180min at 1300°C constant temperature reaction 3 , into 200sccm N 2 , at N 2The temperature was cooled to room temperature in the atmosphere, and the crude product was obtained. Then the obtained product is washed with ultrasonic water for 5 hours, then filtered and dried to obtain boron nitride nanotubes with a purity of more than 99%. The obtained nanotubes have a diameter of about 500 nm and a length of 10 μm. In this example, 95% yield of the target product can be obtained. figure 1 The SEM image of the obtained BNNT (boron nitride nanotube) prepared for this example. figure 2 It is the TEM topography figure of the BNNT obtained in this example. image 3 and Figure...

Embodiment 2

[0041] Embodiment 2 takes Al 4 B 2 o 9 Nano-whiskers 2g were placed in an open alumina crucible, and then placed in a tube furnace. The furnace tube was purged of air by blowing 1000 standard milliliters per minute (sccm) of Ar. Then 200sccm Ar and 200sccm NH 3 The temperature was raised to 1300°C. Turn off the NH after reacting at a constant temperature of 1300°C for 4h 3 , 500 sccm of Ar was introduced to cool down to room temperature, and the crucible was taken out to obtain a crude product. Then the obtained product is ultrasonically pickled with 3 mol / L nitric acid for 1 h, filtered and dried to obtain boron nitride nanotubes with a purity of more than 99%. In this example, a 90% yield of the target product can be obtained. Figure 5 The SEM image of the BNNT obtained in this example shows that the average diameter of the BNNT nanotube is about 20 nm. Figure 6 It is the Raman image of the BNNT obtained in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com