Organosilane compound, filler, resin composition and copper clad laminate

An organosilane and compound technology, applied in the field of resin composition systems, can solve the problems of aggravated particle collision, high dielectric loss, and high energy consumption, and achieve the effects of reducing water absorption, good moisture resistance, and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0132] Example 1. A method of organosilane synthesis:

[0133] Step a. Add 80 mol of decalin (decalin, Guangzhou Suzhe Chemical Co., Ltd.) and 80 mol of chlorine gas (6061AL, Xinhai Chemical Instrument Co., Ltd., Taocheng District, Hengshui City) into a clean reactor, and then pass light (light intensity) 50cd) 5h and rectification to obtain 60mol The chemical structure is Compound.

[0134] Step b. Add 60mol to a clean reactor (Ethylene, Chengdu Tairong Industrial Gas Co., Ltd.) and 60mol of HCl (Hydrogen Chloride, Xinjiang Tianye Group) were heated at 105°C for 7 hours under 2 atmospheres to obtain 50mol

[0135] Step c. The chemical structural formula of 50 mol in a clean reactor is Compound and 50mol At a temperature of 112°C, 3 atmospheres, heating at 105°C for 6 hours to obtain a chemical structure of 40 mol is compound of.

[0136] Step d. The chemical structure of 40 mol in a clean reactor is And add 100mol of concentrated sulfuric acid (Sulfuric acid, Changshu Jinyou C...

Embodiment 2

[0138] Example 2: A preparation method of a low-polarity compound.

[0139] Step S1: Add 70mol of benzene (Benzene, Zhengzhou Chaoan Import and Export Trade Co., Ltd.) and 70mol of chlorine (6061AL, Xinhai Chemical Instrument Co., Ltd., Taocheng District, Hengshui City) into a clean reactor, and then pass light (light intensity 40cd) ) The chemical structure of 50mol obtained by 8h and distillation is compound of.

[0140] Step S2: Add 50mol into a clean reaction kettle. The chemical structure is The compound and 100 mol of Mg (magnesium powder, Hebi Minshan Metal Products Co., Ltd.) in 300 mol of Et20 (ether, Suzhou Huayuan Chemical) solvent, heated at 75 ℃ at 2 atmospheres for 6 hours to obtain the chemical structure of 40 mol compound of.

[0141] Step S3: Add 40 mol of ethyl chloride (ethyl chloride, Lianyungang Ruiwei Chemical Co., Ltd.) into the above reaction kettle, and heat at 83°C for 6 hours at 1 atmosphere to obtain a chemical structure of 30 mol. compound of.

[0142]...

Embodiment 3

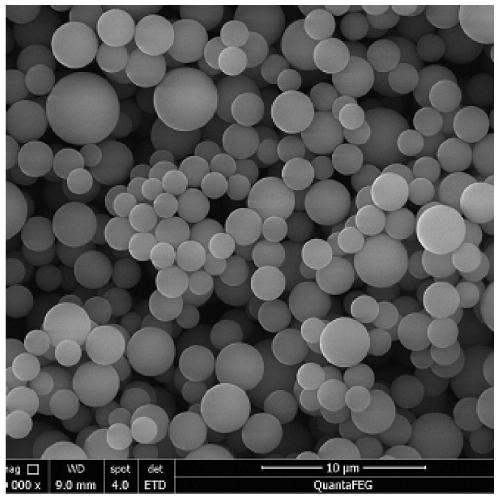

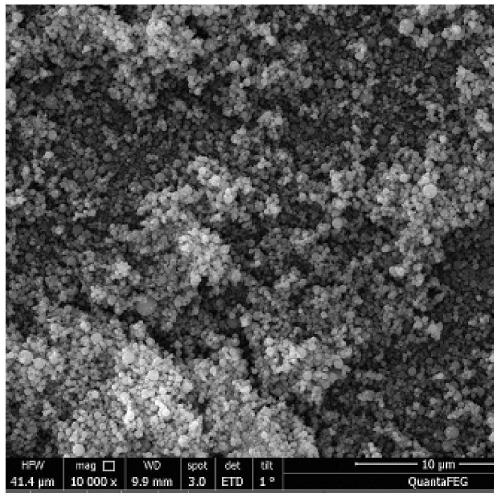

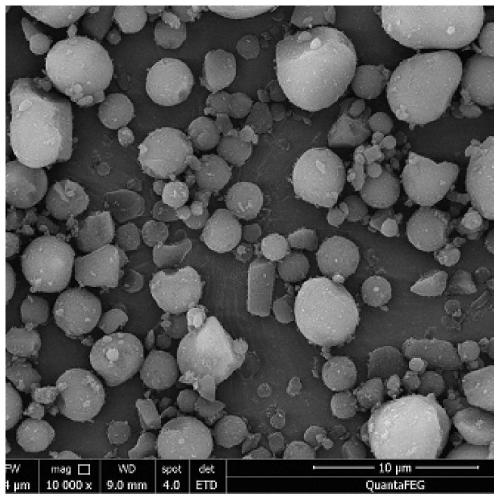

[0145] Example 3: Preparation of a spherical silica filler,

[0146] Step N1: In a clean reactor, add 32 mol Make a mixed solution with 6mol pure water (homemade);

[0147] Step N2: Add an appropriate amount of ammonia (ammonia, Chengdu Lianhe Chemical & Pharmaceutical Co., Ltd.) to the mixed solution in step N1, so that the pH of the system is 10, the stirring speed of the reactor is 2300 rpm, and the reaction is at 5 atmospheres for 7 hours. Spherical silica slurry;

[0148] Step N3: Pass the prepared slurry through a filter press (filter press, Hangzhou Yulong Filter Press Co., Ltd.) to a water content of 0.5%, and pass the filtered material through a tunnel oven (LC- KH0123 Shenzhen Licheng Hardware Electric Heating Equipment Co., Ltd.) Bake to a moisture content of 0.08%;

[0149] Step N4: The dried material is classified by a classifier (classifier, Weifang Guote) to obtain spherical silica filler.

[0150] Conclusion: This is a preferred example: organic functional group conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com