Monolayer carbon nitride nanoflake and bismuth plasma co-modified bismuth oxide-based electrode as well as preparation method and application thereof

A technology of plasma and nanosheets, applied in chemical instruments and methods, special compound water treatment, physical/chemical process catalysts, etc., can solve the problems of general effect, poor photoresponse performance, and few catalytic reaction active sites, etc., to achieve The treatment effect is good, the preparation method is simple, and the effect of visible light response improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Taking the optimal preparation method as an example, it includes the following steps:

[0056] (1) Dissolve bismuth nitrate pentahydrate in HNO 3 In the ethylene glycol of (1M), form the bismuth nitrate pentahydrate solution of 0.2M, stir and dissolve at room temperature, obtain clear solution A;

[0057] (2) Take 5g of melamine solid, place it in a crucible and calcinate at 520°C for 2h under air atmosphere to obtain C 3 N 4 solid;

[0058] (3) Weigh 0.5g of C 3 N 4 The solid was placed in 100ml of ethanol solution and ultrasonically stripped for 12 hours to obtain a single layer of C 3 N 4 After centrifugation, take the supernatant as solution B; take 1ml of B turbid solution and add it to 10ml of A solution, stir and disperse evenly to obtain mixed solution C;

[0059] (4) Take 0.02ml of solution C and drop-coat it on the conductive glass (FTO), and dry it in a vacuum oven at 80°C for 2 hours;

[0060] (5) Take out the dried FTO and put it into a muffle furna...

Embodiment 1

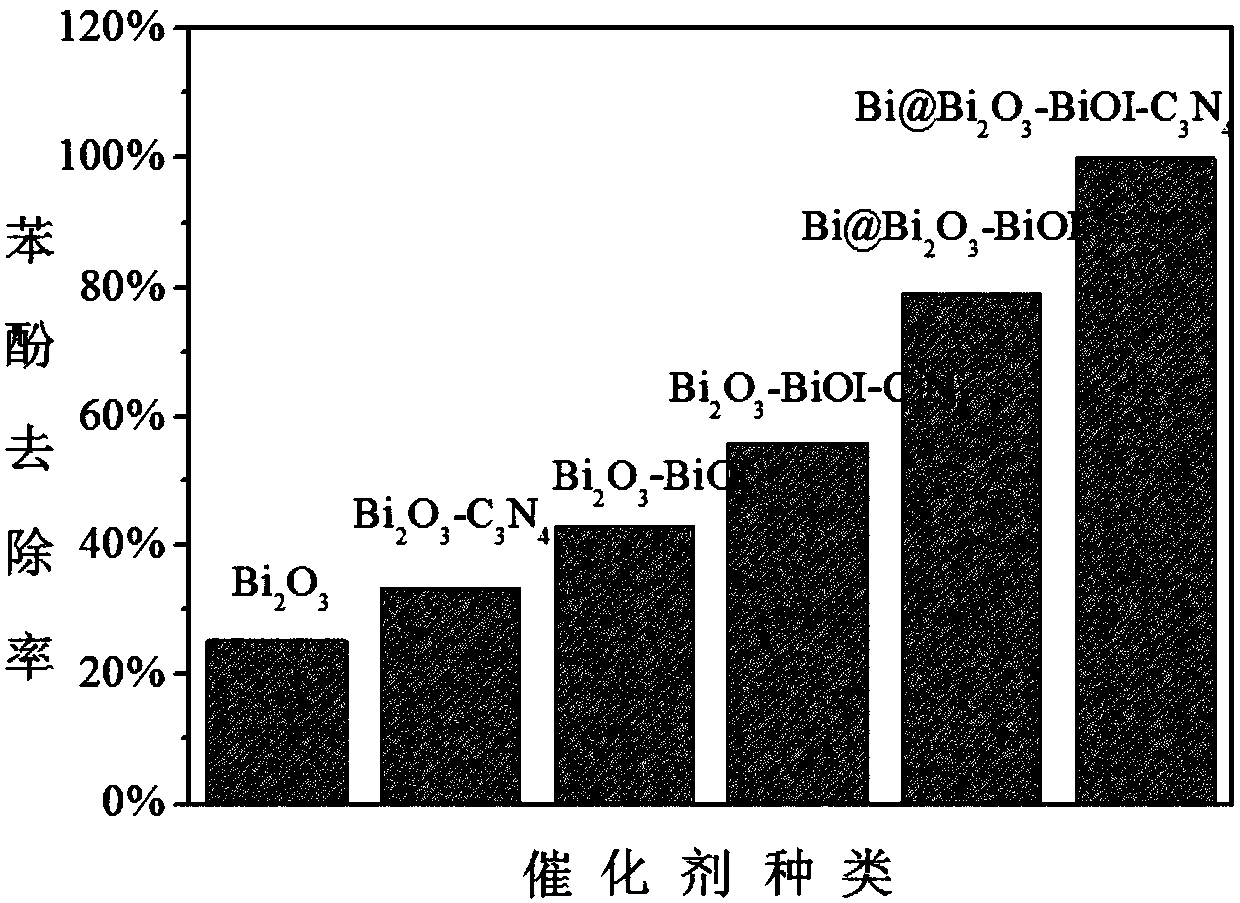

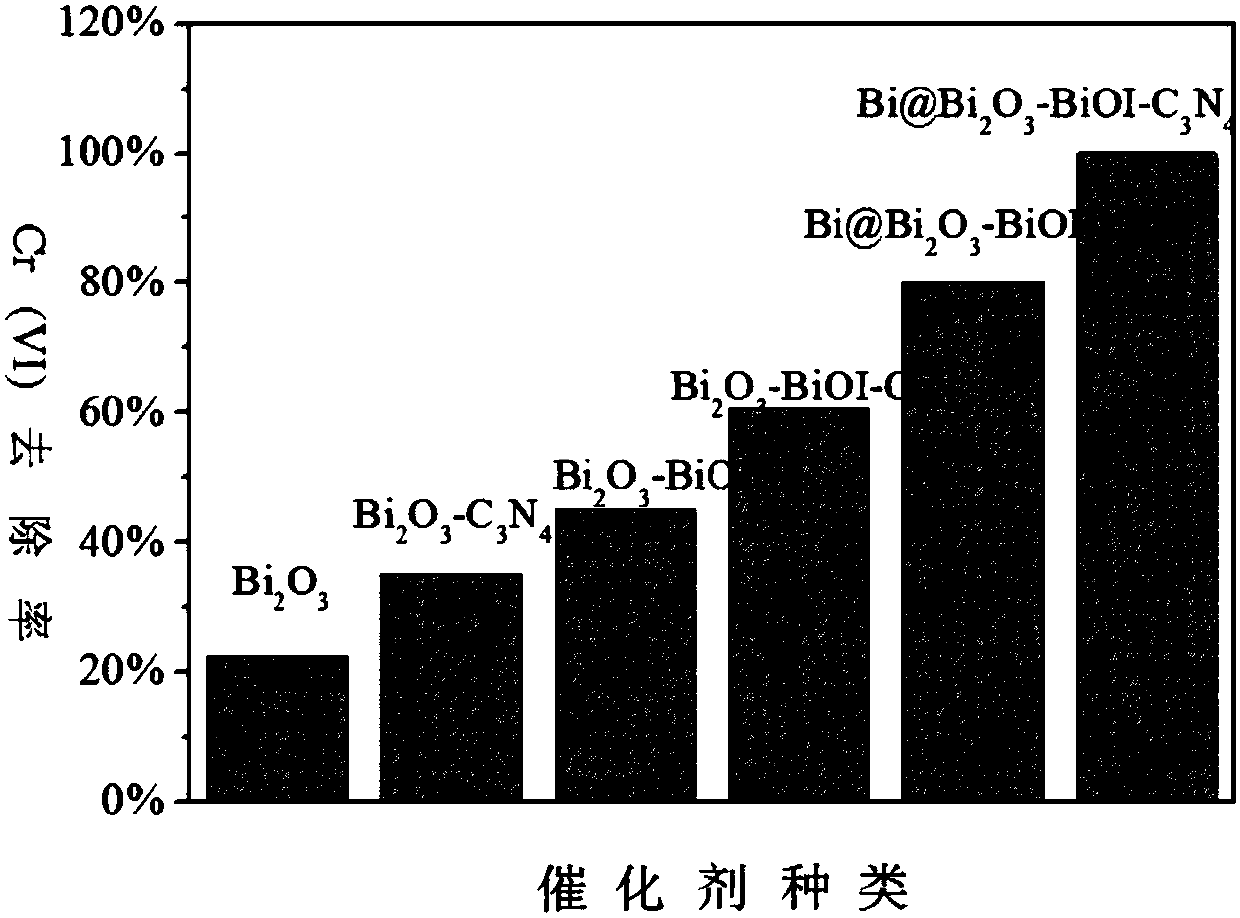

[0064] Respectively against Bi 2 o 3 , Bi 2 o 3 -C 3 N 4 , Bi 2 o 3 -BiOI, Bi 2 o 3 -BiOI-C 3 N 4 , Bi@Bi 2 o 3 -BiOI, Bi 2 o 3 -BiOI-C 3 N 4 , Bi@Bi 2 o 3 -BiOI-C 3 N 4 A series of catalytic membranes were tested for the degradation kinetics of chromium-containing phenol wastewater. The concentration of phenol was 5 mg / L, and the concentration of chromium was 80 μmol / L. After the adsorption equilibrium was stirred in the dark, the light source and power supply (2.5V bias voltage) were turned on, and the reaction was carried out for 3 hours.

[0065] The photocatalytic degradation effects of different catalytic films under visible light conditions are as follows: figure 1 and figure 2 shown. To verify Bi@Bi 2 o 3 -BiOI-C 3 N 4 Compared with the photocatalytic performance of the substrate and any binary composite catalyst, the photocatalytic performance has been significantly improved, from figure 1 It can be seen from the data that the five catalyt...

Embodiment 2

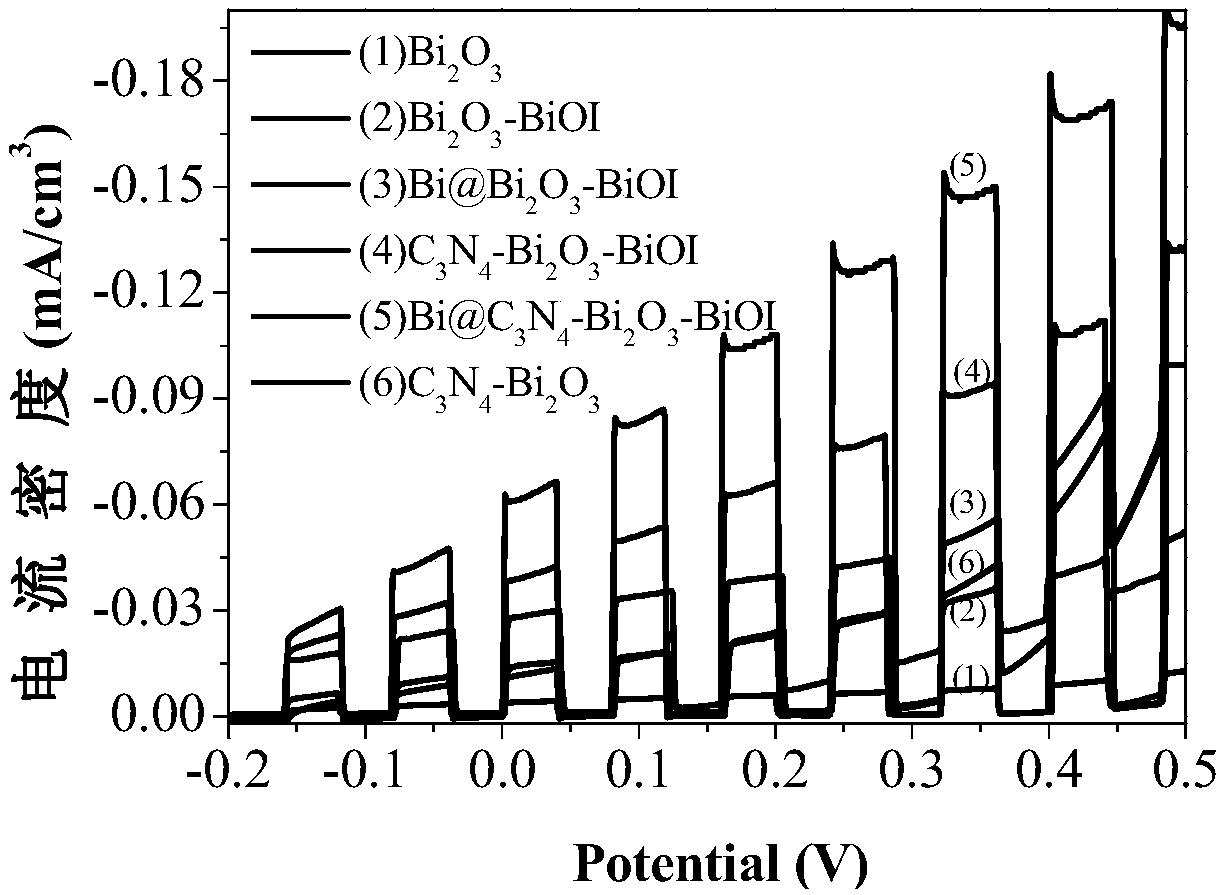

[0067] Determination of Bi@Bi by Electrochemical Workstation 2 o 3 -BiOI-C 3 N 4 Photochemical performance test of Bi@Bi 2 o 3 -BiOI-C 3 N 4 The film electrode is the working electrode, the Pt sheet is the counter electrode, the Ag / AgCl is the reference electrode, and the Na 2 SO 4 (0.1mol / L) and Na 2 SO 3 (0.1mol / L) solution is the electrolyte. via Bi@Bi 2 o 3 -BiOI electrodes were scanned to obtain volt-ampere curves. The light source in this experiment was a xenon lamp (500W). Under the condition that the positions of the electrodes and the light source were consistent, scanning of visible light was carried out respectively. And with Bi 2 o 3 , Bi 2 o 3 -C 3 N 4 , Bi 2 o 3 -BiOI, Bi 2 o 3 -BiOI-C 3 N 4 The photocurrents of the electrodes under visible light were compared.

[0068] From image 3 It can be seen that Bi@Bi 2 o 3 -BiOI-C 3 N 4 The photocurrent of the electrode is significantly higher than that of any other electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com