Charcoal-base microbial compound fertilizer and preparation method thereof

A technology of microorganisms and compound fertilizers, applied in the field of compound fertilizers, can solve the problems of aggravating the greenhouse effect, the decline of agricultural product quality and environmental quality, groundwater pollution, etc., and achieve the effect of simple process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

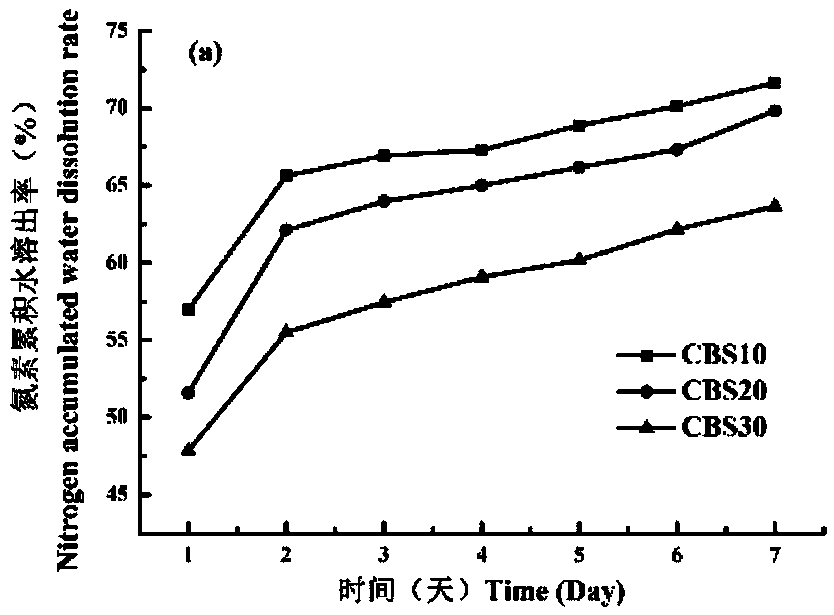

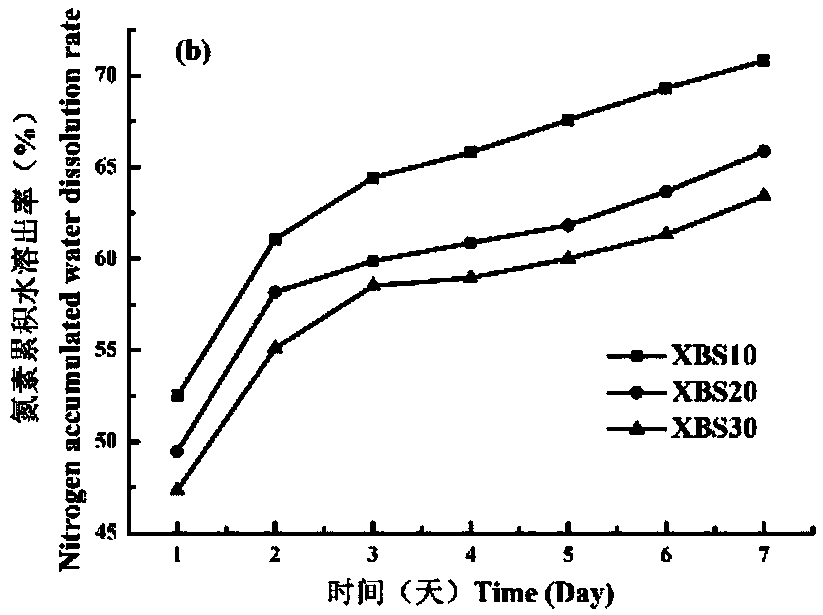

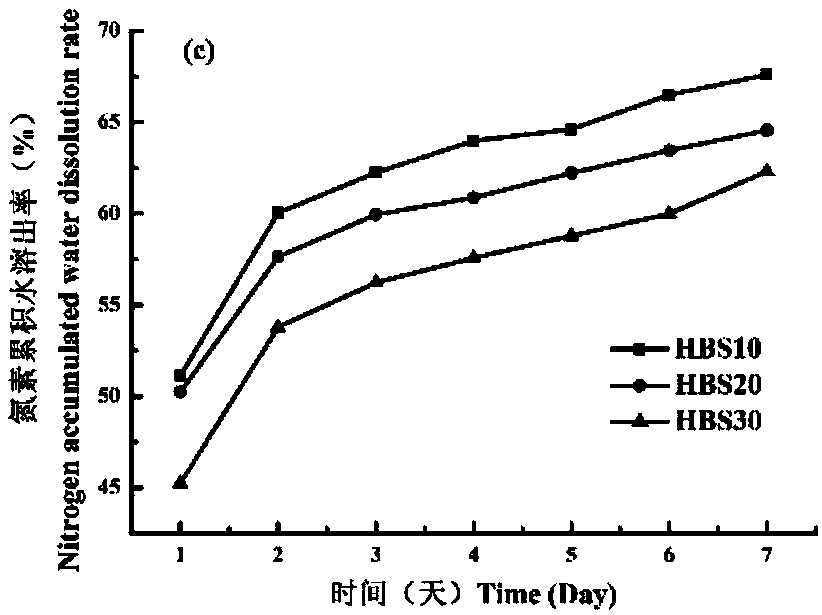

Image

Examples

Embodiment 1

[0048] A carbon-based microbial compound fertilizer, which is prepared by microbial compound fertilizer, coating agent, biochar and zeolite in a weight ratio of 100:10:10:5; the microbial compound fertilizer is composed of nitrogen fertilizer, phosphate fertilizer, potash fertilizer and nitrogen-fixing microorganisms, and the microorganism The weight percent of each component in the compound fertilizer is 45wt% of nitrogen fertilizer, 23.5wt% of phosphate fertilizer, 23.5wt% of potash fertilizer, 7% of nitrogen-fixing microorganism; The weight percent of the aqueous solution is 50wt%, and the weight percent of the attapulgite is 50wt%;

[0049] The nitrogen fertilizer is ammonium nitrate, the phosphate fertilizer is calcium superphosphate, and the potassium fertilizer is potassium sulfate; the nitrogen-fixing microorganism is Bacillus subtilis, here is Bacillus subtilis spore powder; the polyvinyl alcohol aqueous solution is 3wt% polyvinyl alcohol aqueous solution; The attapul...

Embodiment 2

[0055] A carbon-based microbial compound fertilizer, which is prepared by microbial compound fertilizer, coating agent, biochar and zeolite in a weight ratio of 100:12:20:15; the microbial compound fertilizer is composed of nitrogen fertilizer, phosphate fertilizer, potash fertilizer and nitrogen-fixing microorganisms, and the microorganism The percentage by weight of each component in the compound fertilizer is 50wt% of nitrogen fertilizer, 24wt% of phosphate fertilizer, 24wt% of potash fertilizer, 2wt% of nitrogen-fixing microorganism; The weight percentage is 75wt%, and the weight percentage of attapulgite is 25wt%;

[0056] The nitrogen fertilizer is ammonium bicarbonate, the phosphate fertilizer is calcium heavy phosphate, and the potassium fertilizer is potassium nitrate; the nitrogen-fixing microorganism is Bacillus subtilis, here is Bacillus subtilis spore powder; the polyvinyl alcohol aqueous solution is 6wt% polyvinyl alcohol aqueous solution; attapulgite is Cross th...

Embodiment 3

[0062] A carbon-based microbial compound fertilizer, which is prepared by microbial compound fertilizer, coating agent, biochar and zeolite in a weight ratio of 100:15:30:10; the microbial compound fertilizer is composed of nitrogen fertilizer, phosphate fertilizer, potash fertilizer and nitrogen-fixing microorganisms, and the microorganism The weight percent of each component in the compound fertilizer is 47.5wt% of nitrogen fertilizer, 23.75wt% of phosphate fertilizer, 23.75wt% of potash fertilizer, 5wt% of nitrogen-fixing microorganism; Coating agent is made up of attapulgite and polyvinyl alcohol aqueous solution, and polyethylene The weight percent of alcohol aqueous solution is 60wt%, and the weight percent of attapulgite is 40wt%;

[0063] The nitrogen fertilizer is urea, the phosphate fertilizer is calcium superphosphate, and the potassium fertilizer is potassium chloride; the nitrogen-fixing microorganism is Bacillus subtilis, here is Bacillus subtilis spore powder; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com