Method of Boehmite Composite Alkaline Ionic Liquid Catalyzed Transesterification Reaction

A technology of transesterification and basic ions, applied in catalytic reactions, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve catalyst recovery and recycling loss, increase equipment investment and operation Difficulty, harsh process conditions of transesterification reaction, etc., to achieve the effect of reducing equipment investment, facilitating large-scale industrial production, and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

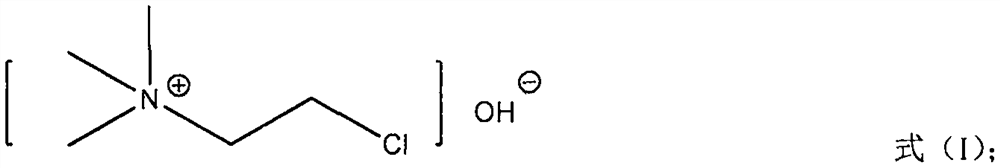

[0031] Preparation of basic ionic liquid: In a 100mL round bottom flask, add 0.1mol (15.8g) (2-chloroethyl) trimethyl ammonium chloride, 0.1mol (5.61g) potassium hydroxide and 30mL absolute ethanol, room temperature Under the conditions, stirring and reacting for 2 to 3 hours, filtering to remove potassium chloride precipitate, reducing price distillation to remove the ethanol solvent, vacuum drying to obtain a colorless liquid which is the target ionic liquid, and the yield is 95%;

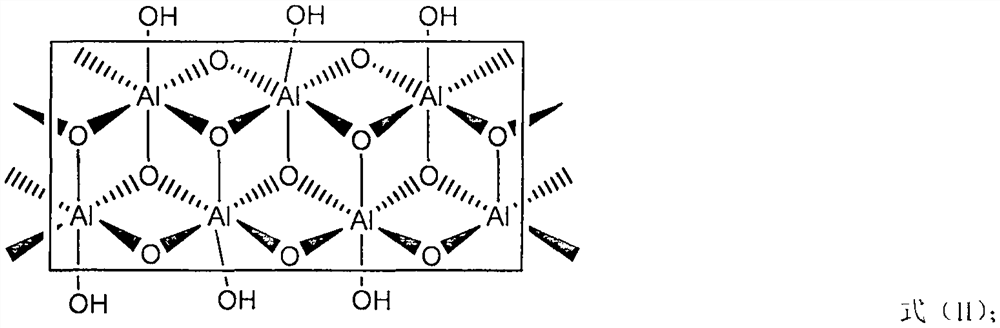

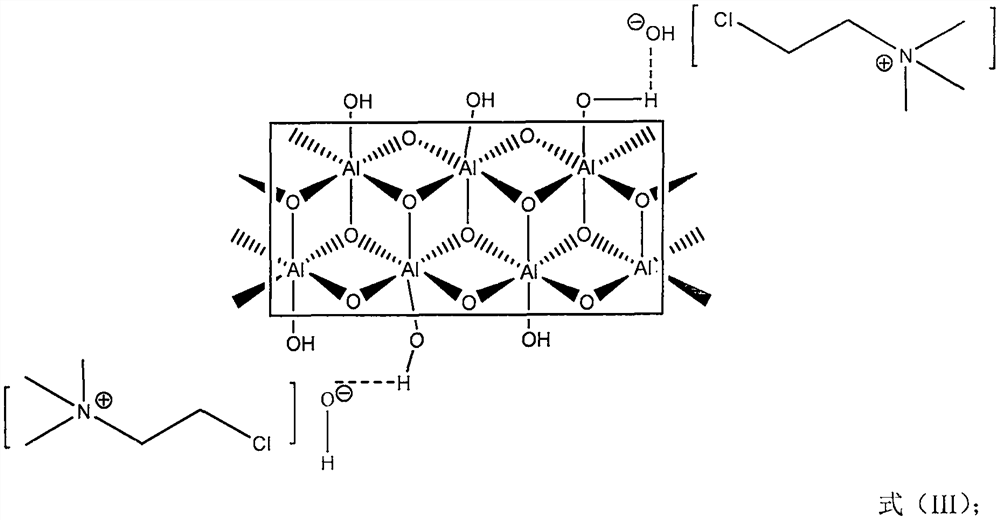

[0032] Boehmite composite ionic liquid: in a 50mL round bottom flask, add alkaline ionic liquid, boehmite (mass percentage of alkaline ionic liquid and boehmite=1:0.5~1.0), and 20mL cyclohexane successively, Stir and react under reflux for 5-6 hours, cool, filter, wash with absolute ethanol, and dry to obtain the target compound ionic liquid complex with a yield of 98%.

Embodiment 2

[0034] In a 100mL round bottom flask, add 0.067mol (20g) of fatty acid methyl ester, 0.067mol (4.97g) of n-butanol and 0.1g of boehmite composite basic ionic liquid catalyst, heat to 58°C, and mix and stir under normal pressure React for 1.0 hour, cool to room temperature, filter to separate and recover the catalyst, transfer the filtrate to a separatory funnel and let it stand for stratification. The lower layer is a mixture of methanol and unreacted butanol. Pressure distillation separates methanol and butanol, which can be reused; the upper layer is the crude product of fatty acid n-butyl ester, washed with water, dried, and can be refined by distillation under reduced pressure at 400Pa or rectification with a rectifying tower, and the yield is 81 %.

Embodiment 3

[0036] In a 100mL round bottom flask, add 0.067mol (20g) of fatty acid methyl ester, 0.067mol (4.97g) of n-butanol and 1.0g of boehmite composite basic ionic liquid catalyst, heat to 62°C, and mix and stir under normal pressure After reacting for 6.0 hours, it was cooled to room temperature, and the remaining operations were the same as in Example 2, and the yield was 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com