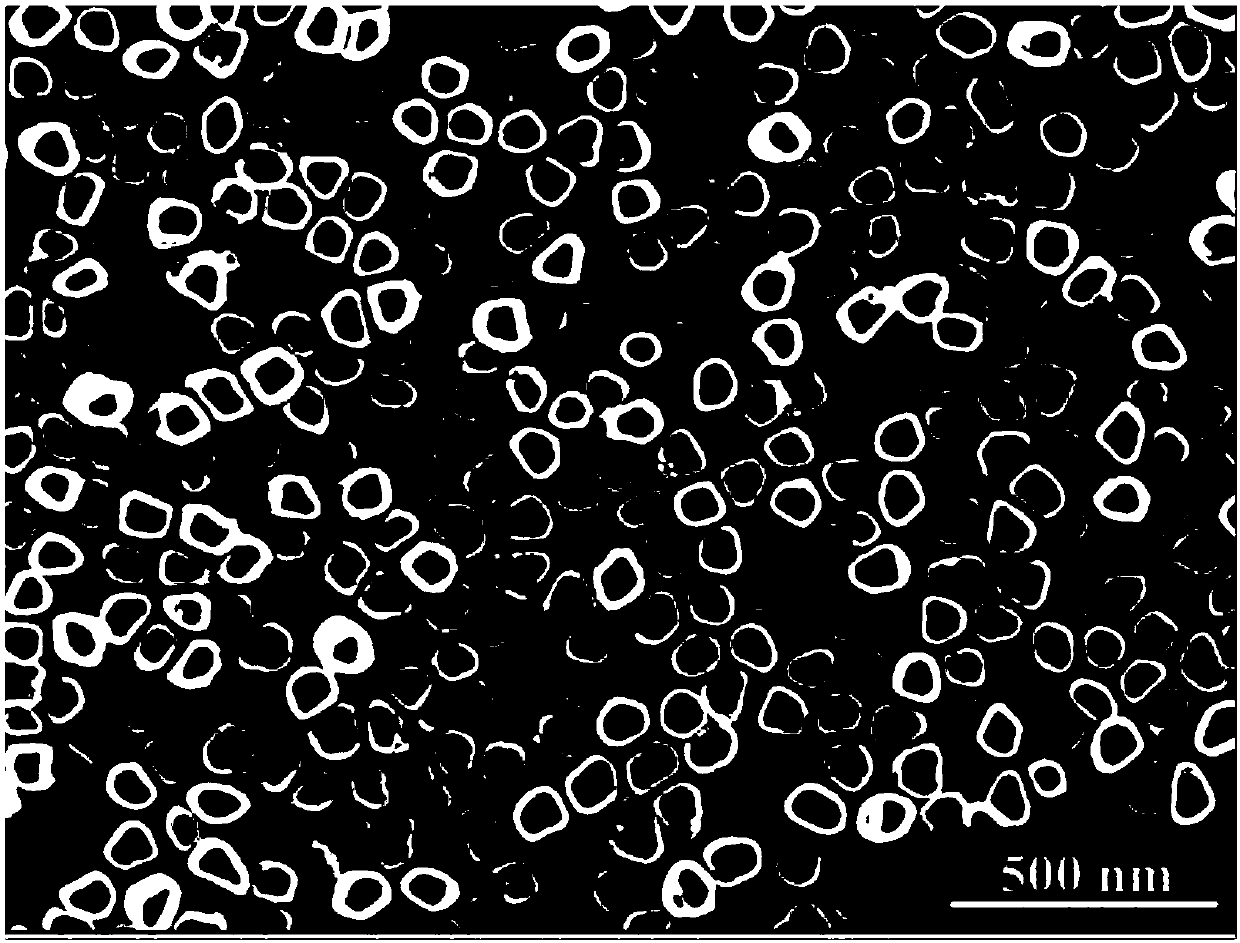

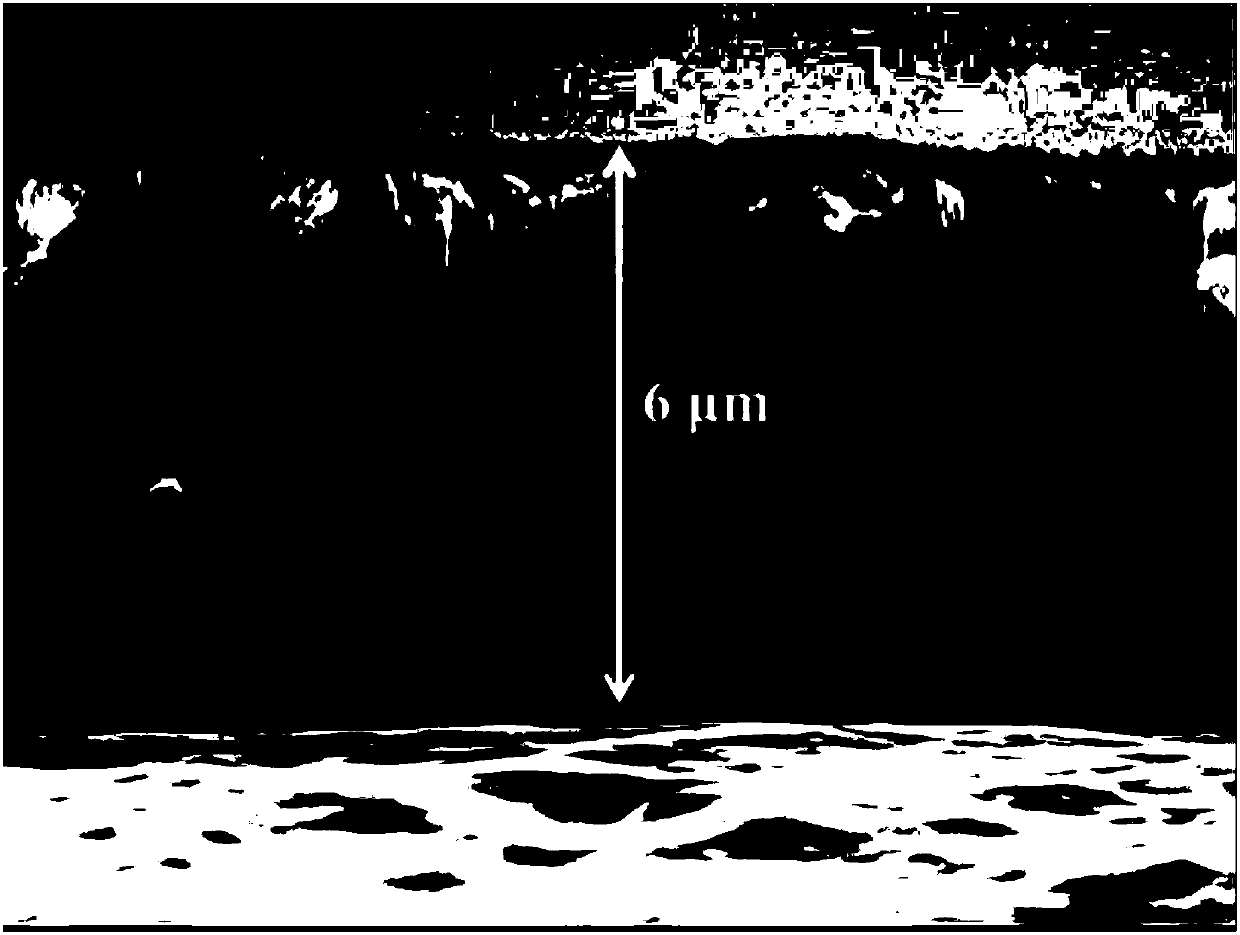

Preparation method of tungsten-doped titanium dioxide nanotube array

A nanotube array, titanium dioxide technology, applied in nanotechnology, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problems of controllable W element distribution and doping amount, and achieve good binding force, simplified process flow, convenient effect of regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1, titanium sheet pretreatment;

[0028] Step 2: Weighing 0.8 wt% ammonium fluoride (about 0.92 g) was dissolved in 35 mL of water, stirred for 10 minutes, and fully dissolved to obtain an ammonium fluoride aqueous solution.

[0029] Step 3. Add 0.04wt% (about 0.05g) sodium tungstate dihydrate to the ammonium fluoride aqueous solution in step 2, stir magnetically for 10 minutes, then add 65mL glycerol, and stir magnetically at 50°C After 30 minutes, the solution was mixed uniformly to obtain an electrolyte solution.

[0030] Step 4. Connect the titanium sheet pretreated in step 1 to the positive electrode of the constant voltage DC power supply, and the graphite sheet or platinum sheet to the negative electrode of the power supply, and simultaneously immerse it in the electrolyte solution of step 3, constant voltage 30V, electrode spacing 3cm, electrolyte constant temperature 25°C. The anodizing time was set at 3 hours, and the whole process was accompanied by ma...

Embodiment 2

[0034] The preparation process is substantially the same as in Example 1, except that:

[0035] (1) In the ammonium fluoride aqueous solution in step 2, add sodium tungstate dihydrate with a mass percentage of 0.08wt% (about 0.10g), stir magnetically for 10 minutes, then add 65mL glycerol, and stir magnetically at 50°C After 30 minutes, the solution was mixed uniformly to obtain an electrolyte solution.

[0036] (2) Connect the titanium sheet pretreated in step 1 to the positive electrode of the constant voltage DC power supply, and the graphite sheet or platinum sheet to the negative electrode of the power supply and simultaneously immerse it in the electrolyte solution with a constant voltage of 35V, an electrode spacing of 3cm, and a constant temperature of the electrolyte at 25°C. The anodizing time was set at 3 hours, and the whole process was accompanied by magnetic stirring. After the anodizing process is completed, the sample is taken out, ultrasonically cleaned with ...

Embodiment 3

[0040] The preparation process is substantially the same as in Example 1, except that:

[0041] (1) In the ammonium fluoride aqueous solution in step 2, add sodium tungstate dihydrate with a mass percentage of 0.16wt% (about 0.20g), stir magnetically for 10 minutes, then add 65mL glycerol, and stir magnetically at 50°C After 40 minutes, the solution was mixed uniformly to obtain an electrolyte solution.

[0042] (2) Connect the titanium sheet pretreated in step 1 to the positive electrode of the constant voltage DC power supply, and the graphite sheet or platinum sheet to the negative electrode of the power supply and simultaneously immerse it in the electrolyte solution with a constant voltage of 35V, an electrode spacing of 3cm, and a constant temperature of the electrolyte at 25°C. The anodizing time was set at 4 hours, and the whole process was accompanied by magnetic stirring. After the anodizing process is completed, the sample is taken out, ultrasonically cleaned with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com