Fabrication method of Sb2S3-based full-inorganic thin film solar cell

A technology of solar cells and inorganic thin films, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor battery stability, easy to agglomerate, and limit the application of antimony sulfide, and achieve the effect of good stability and large open-circuit photovoltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

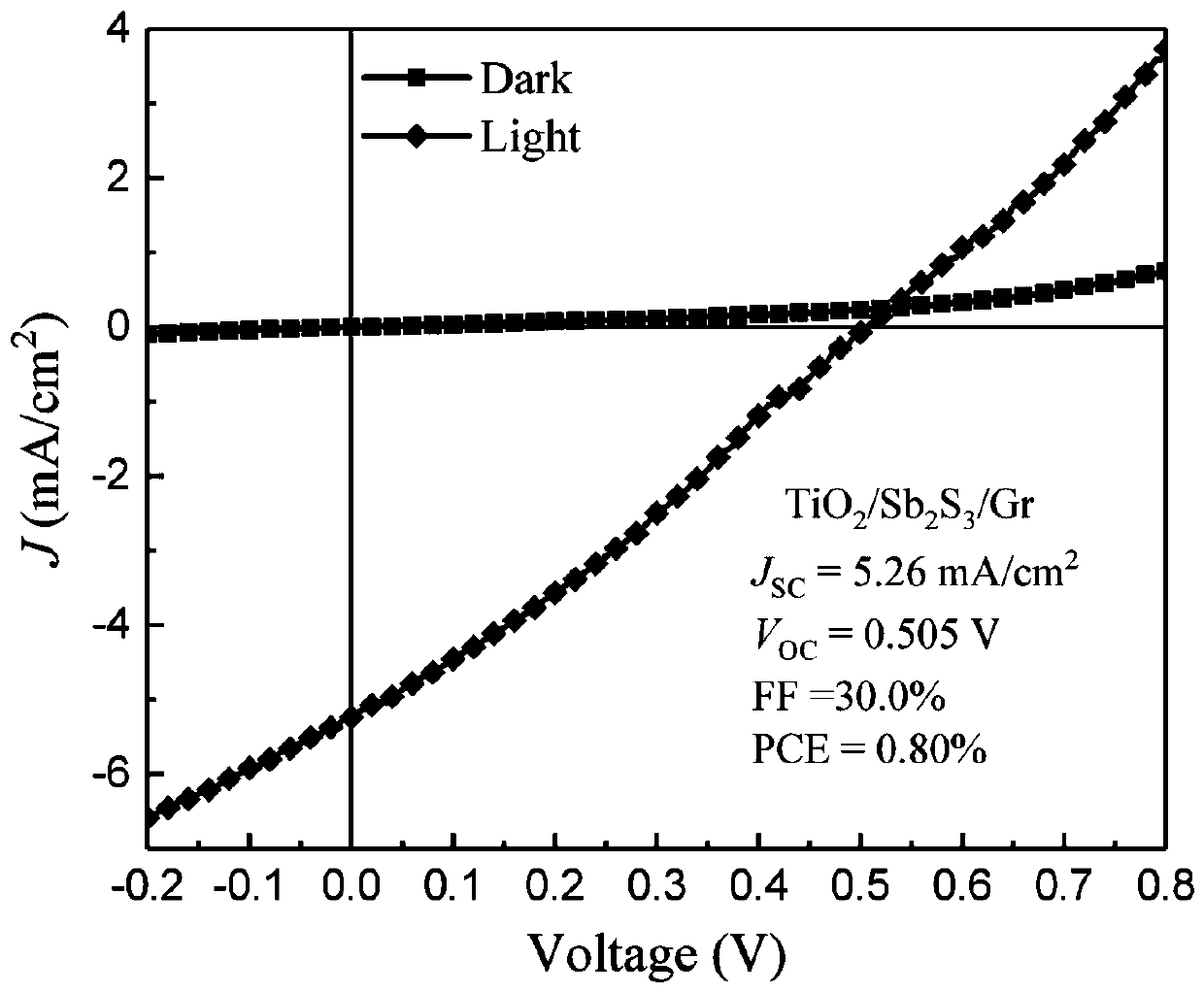

Embodiment 1

[0021] The preparation process and steps of this embodiment are as follows:

[0022] (1) Substrate pretreatment: SnO doped with fluorine 2 Transparent conductive glass (FTO) (~7 Ω sq) was used as the substrate, which was ultrasonically cleaned with deionized water, ethanol and acetone for 5-15 minutes to remove impurities and organic matter on the surface, and then rinsed with deionized water and cleaned with argon. Air-dried for later use;

[0023] (2) TiO 2 Film preparation: first configure 2.5mL of 0.5mol / L titanium tetraisopropoxide ethanol solution, in which the purity of titanium tetraisopropoxide is 99.8%; at the same time configure 2.5mL 0.04mol / L hydrochloric acid ethanol solution; After the solution was mixed evenly, it was spin-coated on the cleaned FTO, and the edge of the FTO was stuck 0.2cm with a high-temperature tape before the spin-coating as the back electrode of the battery; finally, the FTO with the titanium dioxide precursor was put into a tubular resist...

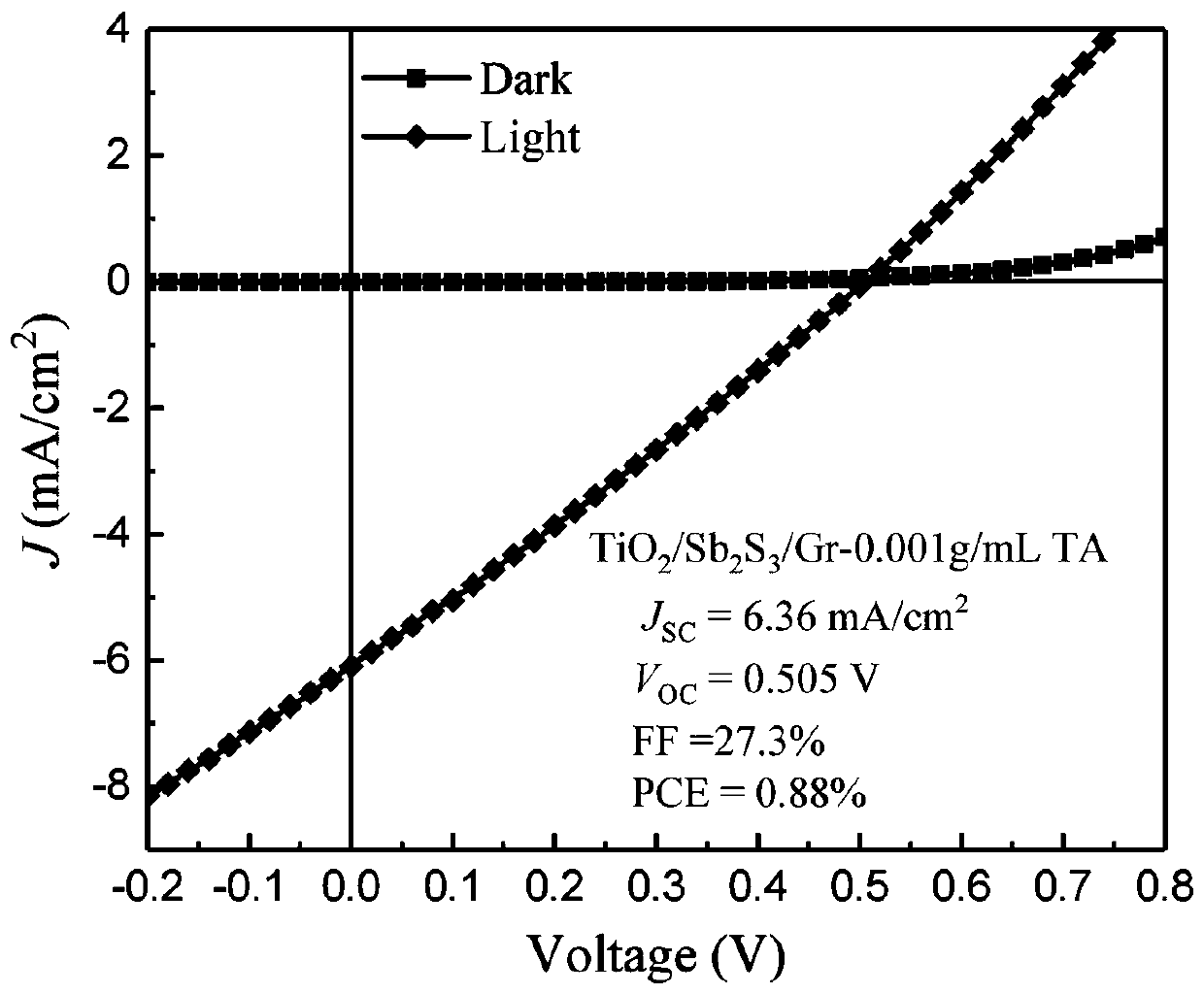

Embodiment 2

[0028] The preparation process and steps of this embodiment are as follows:

[0029] (1) Substrate pretreatment: SnO doped with fluorine 2Transparent conductive glass (FTO) (~7 Ω sq) was used as the substrate, which was ultrasonically cleaned with deionized water, ethanol and acetone for 5-15 minutes to remove impurities and organic matter on the surface, and then rinsed with deionized water and cleaned with argon. Air-dried for later use;

[0030] (2) TiO 2 Film preparation: first configure 2.5mL of 0.5mol / L titanium tetraisopropoxide ethanol solution, in which the purity of titanium tetraisopropoxide is 99.8%; at the same time configure 2.5mL 0.04mol / L hydrochloric acid ethanol solution; After the solution was mixed evenly, it was spin-coated on the cleaned FTO, and the edge of the FTO was stuck 0.2cm with a high-temperature tape before the spin-coating as the back electrode of the battery; finally, the FTO with the titanium dioxide precursor was put into a tubular resista...

Embodiment 3

[0035] The preparation process and steps of this embodiment are as follows:

[0036] (1) Substrate pretreatment: SnO doped with fluorine 2 Transparent conductive glass (FTO) (~7 Ω sq) was used as the substrate, which was ultrasonically cleaned with deionized water, ethanol and acetone for 5-15 minutes to remove impurities and organic matter on the surface, and then rinsed with deionized water and cleaned with argon. Air-dried for later use;

[0037] (2) TiO 2 Film preparation: first configure 2.5mL of 0.5mol / L titanium tetraisopropoxide ethanol solution, in which the purity of titanium tetraisopropoxide is 99.8%; at the same time configure 2.5mL 0.04mol / L hydrochloric acid ethanol solution; After the solution was mixed evenly, it was spin-coated on the cleaned FTO, and the edge of the FTO was stuck 0.2cm with a high-temperature tape before the spin-coating as the back electrode of the battery; finally, the FTO with the titanium dioxide precursor was put into a tubular resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com