Biodegradable slow-release carbon source filler and preparation method thereof

A slow-release carbon source and biodegradation technology, applied in chemical instruments and methods, biological water/sewage treatment, water pollutants, etc., can solve the problems of unfavorable microbial attachment, small specific surface area, single nutrition, etc., and achieve excellent physiological inertia , Improve the specific surface area, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

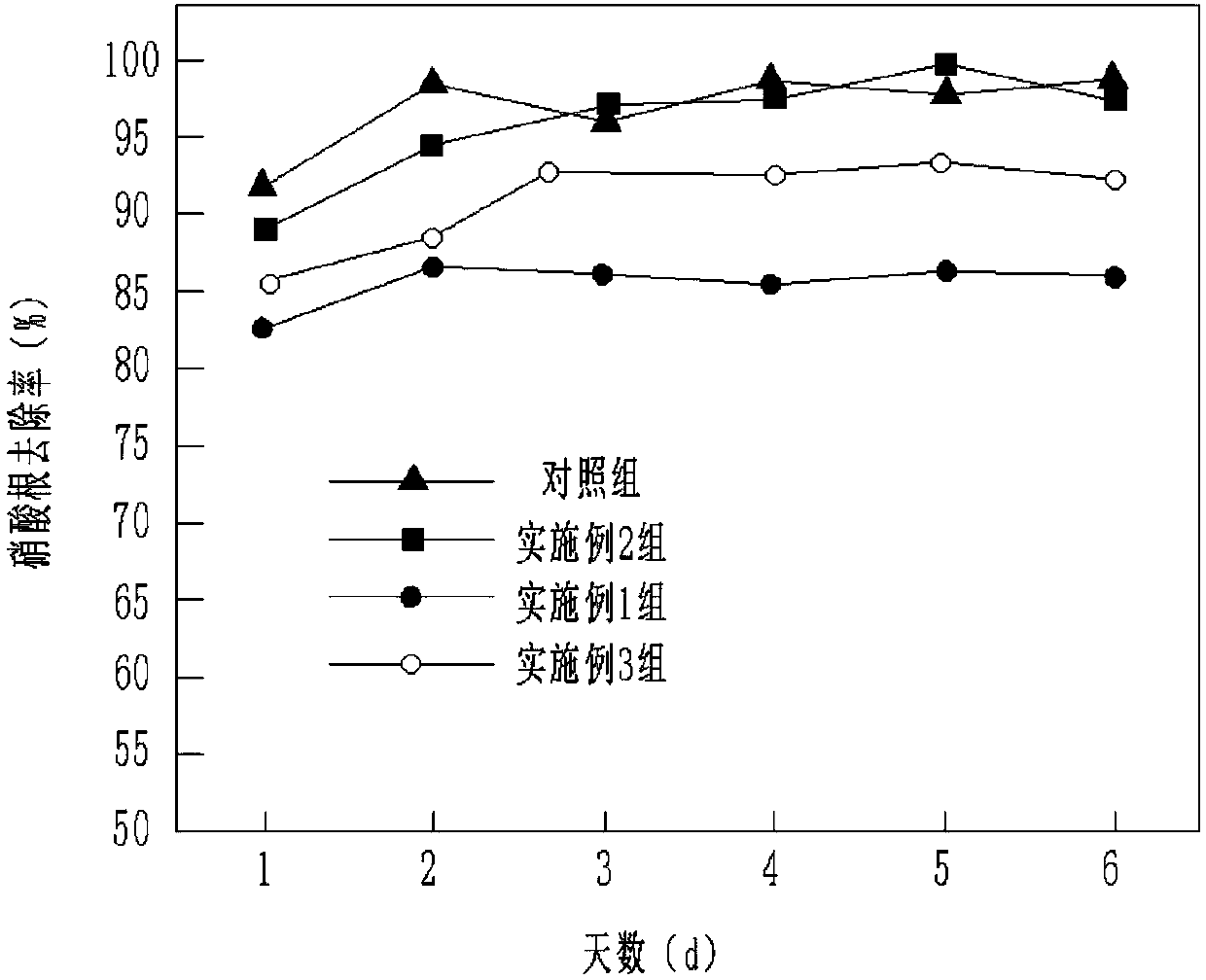

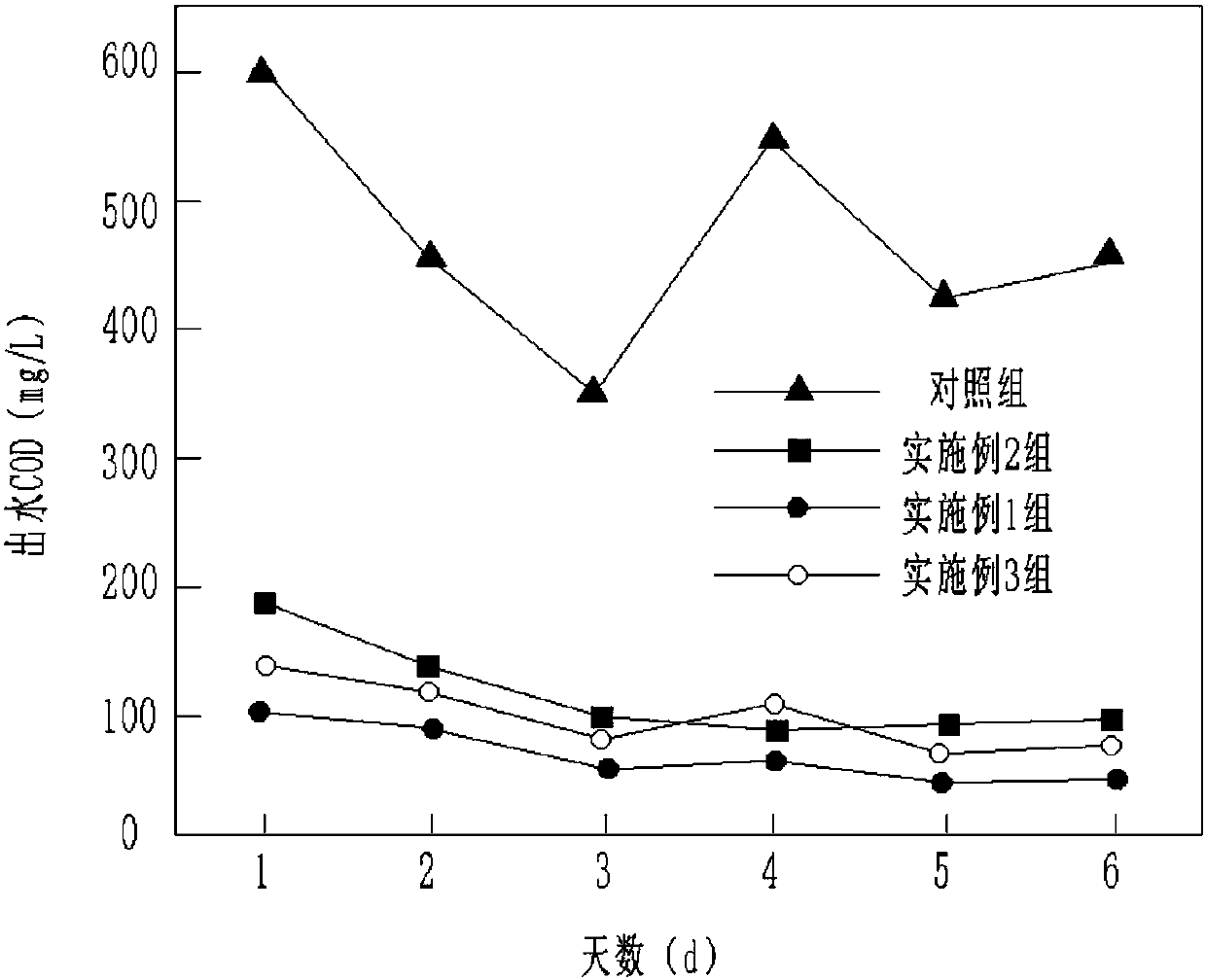

Embodiment 1

[0044] A biodegradable slow-release carbon source filler mainly includes an external carbon source layer, an internal carbon source layer and a connecting colloid, and the mass ratio of the external carbon source layer, the internal carbon source layer and the connecting colloid is: 3:1: 2. The external carbon source layer wraps the internal carbon source layer through the connecting colloid to form a multi-layer spherical structure; the internal specific surface area of the multi-layer structure is large, which is conducive to the attachment of microorganisms.

[0045] The external carbon source layer mainly includes: 25% biodegradable polymer (polyvinyl alcohol), 25% starch (common starch), 3% emulsifier (fatty acid polyglycerol ester), 0.8% catalyst, 6% graphite powder, 6% iron powder, and the balance is hard water;

[0046] Wherein, the preparation method of the external carbon source layer comprises the following steps:

[0047] S1: Mix the biodegradable polymer (polyv...

Embodiment 2

[0070] A biodegradable slow-release carbon source filler mainly includes an external carbon source layer, an internal carbon source layer and a connecting colloid, and the mass ratio of the external carbon source layer, the internal carbon source layer and the connecting colloid is: 4:1: 2.5. The external carbon source layer wraps the internal carbon source layer through the connecting colloid to form a multi-layer spherical structure; the internal specific surface area of the multi-layer structure is large, which is conducive to the attachment of microorganisms.

[0071] The external carbon source layer mainly includes: 28% biodegradable polymer (polyvinyl alcohol), 28% starch (expanded glutinous rice flour), 4% emulsifier (sorbitol glyceride), 1.0% catalyst, 7% graphite powder, 7% iron powder, and the balance is hard water;

[0072] Wherein, the preparation method of the external carbon source layer comprises the following steps:

[0073] S1: Mix the biodegradable polymer...

Embodiment 3

[0096] A biodegradable slow-release carbon source filler mainly includes an external carbon source layer, an internal carbon source layer and a connecting colloid, and the mass ratio of the external carbon source layer, the internal carbon source layer and the connecting colloid is: 5:1: 3. The external carbon source layer wraps the internal carbon source layer through the connecting colloid to form a multi-layer spherical structure; the internal specific surface area of the multi-layer structure is large, which is conducive to the attachment of microorganisms.

[0097] The outer carbon source layer mainly includes: 30% biodegradable polymer (polycaprolactone), 30% starch (acetate starch), 5% emulsifier (sorbitol glyceride), 1.2% catalyst , 8% graphite powder, 8% iron powder, and the balance is hard water;

[0098] Wherein, the preparation method of the external carbon source layer comprises the following steps:

[0099] S1: Mix the biodegradable polymer (polycaprolactone) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com