Biochar filtration system for high-nitrogen wastewater treatment and operation way of biochar filtration system

A filtration system and wastewater treatment technology, which is applied in water/sewage treatment, water treatment parameter control, biological water/sewage treatment, etc., can solve the problems of large area, complex project cost, unstable effluent quality, etc., and meet the construction period Short, strong adsorption performance, prolonging the effect of hydraulic retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

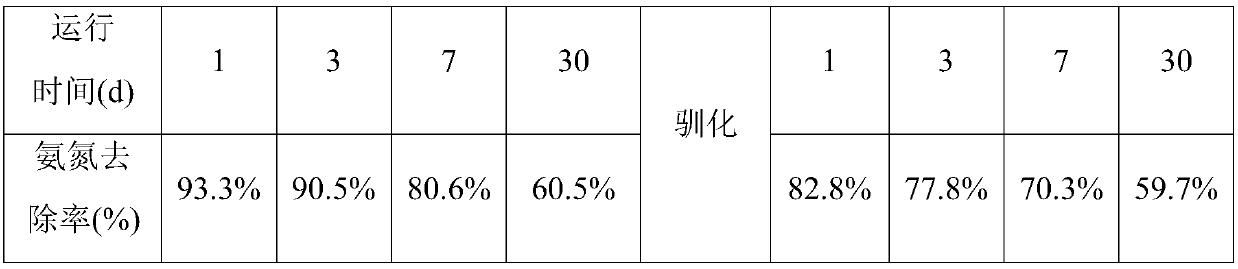

[0021] Adopt biochar high-nitrogen wastewater filtration system of the present invention to process pig farm wastewater, ammonia nitrogen concentration 150mg / L, system height 50cm, large particle biochar, biochar / sponge composite material, biochar / clay mineral composite material and activated biochar Fill in order from top to bottom with a thickness ratio of 7:5:3:1. The activated Bacillus subtilis, Bacillus amyloliquefaciens and yeast were mixed in equal proportions into the system, and the time ratio of the time for the injection of the bacteria liquid into the system and the time for the outflow of the system was adjusted to 1:5, and the acclimation period was 4 days. After the system is acclimatized, let it stand for 1 day, pass it into the waste water of high-nitrogen pig farms, distribute water according to the ratio of water distribution time and drying time of 1:5, run it for 30 days, acclimatize it again, and then run it again, and use the Nessler reagent method to mea...

example 2

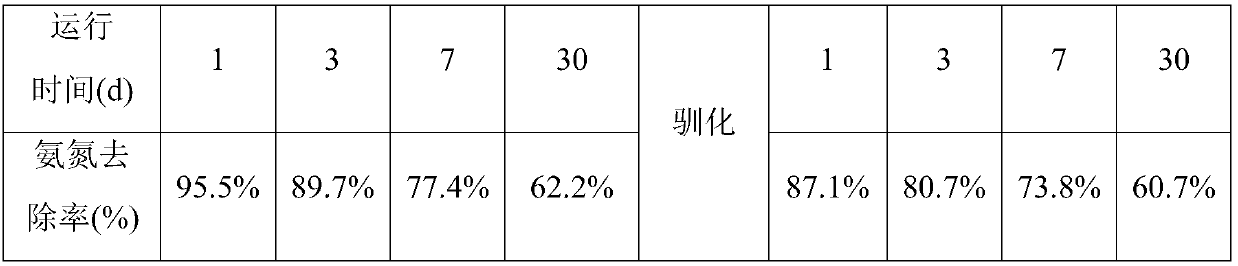

[0025] The biochar high-nitrogen wastewater filtration system of the present invention is used to treat bamboo processing wastewater, the ammonia nitrogen concentration is 100mg / L, and the system height is 50cm. Large particle biochar, biochar / sponge composite material, biochar / clay mineral composite material and activated biochar are filled in order from top to bottom, with a thickness ratio of 7:5:3:1. Activated bacterial solution (mixed in equal proportions of Bacillus licheniformis, Bacillus subtilis, Bacillus amyloliquefaciens, lactic acid bacteria, bifidobacteria, yeast and actinomycetes) is introduced into the system, and the time of injection of the bacterial solution into the system and the flow rate of the outflow system are adjusted. The time ratio is 1:8, acclimation 4d. After the acclimatized system was left standing for 1 day, the waste water from high-nitrogen bamboo processing was introduced, and the water distribution time was 1:8 according to the ratio of wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com