Preparation method of self-repairing fluorocarbon coating for ships

A fluorocarbon coating and self-healing technology, applied in the preparation of microspheres, epoxy resin coatings, coatings, etc., can solve the problems of coating cracks and poor salt spray resistance of fluorocarbon coatings, achieve good fluidity and enhance siphon The effect with broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

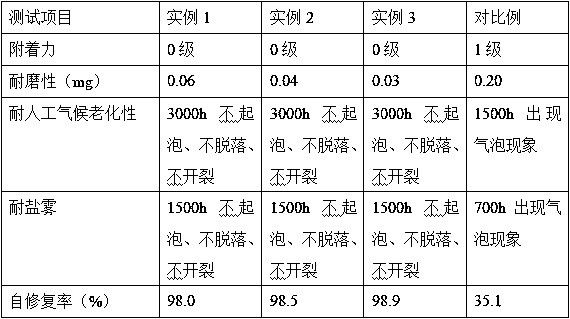

Examples

example 1

[0026]Add 20g of urea and 70mL of formaldehyde solution with a mass fraction of 35% into the Erlenmeyer flask, stir until the urea is completely dissolved, adjust the pH of the reaction system in the Erlenmeyer flask to 8.5 with triethanolamine, put the Erlenmeyer flask into a water bath, Heating to 70°C, keeping it warm for 40 minutes to obtain a viscous transparent liquid, after cooling to room temperature, adjusting the pH to 6.8 with 10% hydrochloric acid to obtain a urea-formaldehyde prepolymer; mix fluorocarbon resin masterbatch with E- 51 type epoxy resin masterbatches were mixed according to the mass ratio of 3:2 to obtain oil-soluble capsule cores, and 100 mL of sodium dodecylbenzenesulfonate solution with a mass fraction of 3% and 40 g of oil-soluble capsule cores were added to the four-necked flask. , 0.5mL n-butanol, start the agitator, stir at a speed of 500r / min, emulsify and disperse for 30min, and obtain an oil-in-water emulsion; add 60mL urea-formaldehyde prepo...

example 2

[0028] Add 23g of urea and 75mL of formaldehyde solution with a mass fraction of 35% into the Erlenmeyer flask, stir until the urea is completely dissolved, adjust the pH of the reaction system in the Erlenmeyer flask to 9.0 with triethanolamine, put the Erlenmeyer flask into a water bath, Heating up to 75°C, keeping it warm for 45 minutes to obtain a viscous transparent liquid, after cooling to room temperature, adjusting the pH to 6.9 with 10% hydrochloric acid to obtain a urea-formaldehyde prepolymer; mix fluorocarbon resin masterbatch with E- 51 type epoxy resin master batches are mixed according to the mass ratio of 3: 2 to obtain oil-soluble capsule cores, and 110 mL of sodium dodecylbenzenesulfonate solution with a mass fraction of 3% and 43 g of oil-soluble capsule cores are added to the four-necked flask. , 0.6mL n-butanol, start the agitator, stir with a rotating speed of 525r / min, emulsify and disperse for 33min, and obtain an oil-in-water emulsion; add 65mL urea-for...

example 3

[0030] Add 25g of urea and 80mL of formaldehyde solution with a mass fraction of 35% into the Erlenmeyer flask, stir until the urea is completely dissolved, adjust the pH of the reaction system in the Erlenmeyer flask to 9.5 with triethanolamine, put the Erlenmeyer flask into a water bath, Heating up to 80°C, keeping it warm for 50 minutes to obtain a viscous transparent liquid, after cooling to room temperature, adjusting the pH to 7.0 with 10% hydrochloric acid to obtain a urea-formaldehyde prepolymer; mixing fluorocarbon resin masterbatch with E- 51 type epoxy resin master batches were mixed according to the mass ratio of 3:2 to obtain oil-soluble capsule core, and 120mL of 3% sodium dodecylbenzenesulfonate solution and 45g oil-soluble capsule core were added to the four-necked flask. , 1.0mL n-butanol, start the agitator, stir with a rotating speed of 550r / min, emulsify and disperse for 35min, and obtain an oil-in-water emulsion; add 70mL urea-formaldehyde prepolymer to 130...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com