High temperature lepidolite hydrothermal treatment method for producing lithium hydroxide

A technology of lithium hydroxide and lepidolite, which is applied in the direction of lithium oxide; Easy to operate, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

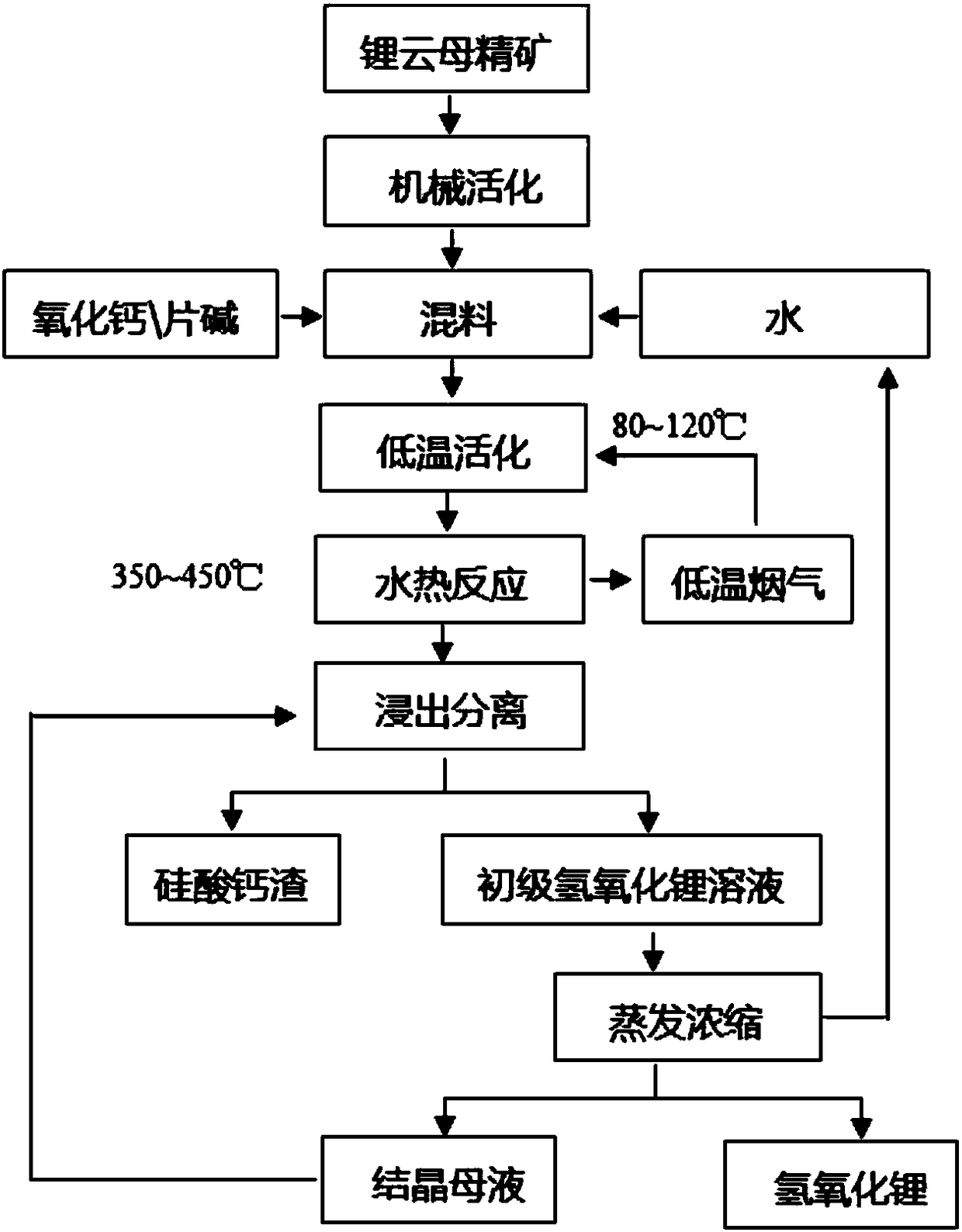

Method used

Image

Examples

Embodiment 1

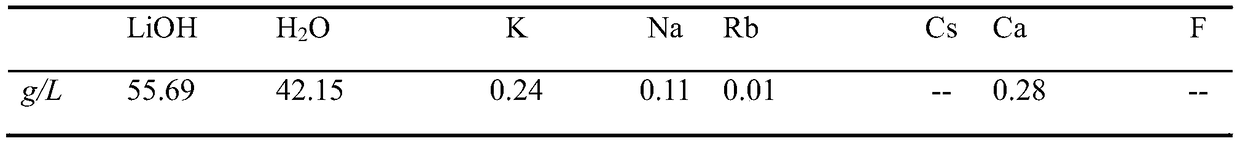

[0033] The lepidolite concentrate is ball milled to an average particle size of 45 μm or less, the slurry overflows into the mixing tank, then granular calcium oxide is added, stirred rapidly, and then transported to the preheated reaction kettle after completion. The ring pipe extends to the reaction kettle, and is directly heated by the exhaust gas of the spray tower, and the temperature is controlled at 100 degrees Celsius for 4 hours. After the preheating reaction, the material is transported to the spray tower by a high-pressure pump, and instantaneous high-temperature water heat occurs at 450 degrees Celsius for 90 seconds. Reaction, after the completion of the hydrothermal reaction, the moisture content of the material is controlled to 20%. Reaction clinker, evaporative concentrated condensate and desalination mother liquor are mixed and leached, and the p-hour value of leaching is accurately controlled to 10 to realize simultaneous leaching and impurity removal. The lea...

Embodiment 2

[0038] The lepidolite concentrate is ball milled to an average particle size of 45 μm or less, the slurry overflows into the mixing tank, then granular calcium oxide is added, stirred rapidly, and then transported to the preheated reaction kettle after completion. The loop pipe extends to the reaction kettle, and is directly heated by the tail gas of the spray tower, and the temperature is controlled at 95 degrees Celsius for 6 hours. After the preheating reaction, the material is transported to the spray tower by a high-pressure pump, and instantaneous high-temperature water heat occurs at 420 degrees Celsius for 80 seconds. Reaction, after the completion of the hydrothermal reaction, the moisture content of the material is controlled to 20%. Reaction clinker, evaporative concentrated condensed water and desalted mother liquor are mixed and leached, and the leaching pH value is precisely controlled to 10 to realize simultaneous leaching and impurity removal. The leaching liqui...

Embodiment 3

[0043]The lepidolite concentrate is ball milled to an average particle size of 45 μm or less, the slurry overflows into the mixing tank, then granular calcium oxide is added, stirred rapidly, and then transported to the preheated reaction kettle after completion. The loop pipe extends to the reaction kettle, and is directly heated by the tail gas of the spray tower. The temperature is controlled at 90 degrees Celsius for 8 hours. After the preheating reaction, the material is transported to the spray tower by a high-pressure pump, and instantaneous high-temperature water heat occurs at 400 degrees Celsius for 90 seconds. Reaction, after the completion of the hydrothermal reaction, the moisture content of the material is controlled to 20%. Reaction clinker, evaporative concentrated condensed water and desalination mother liquor are mixed and leached, and the leaching pH value is precisely controlled to 10 to realize simultaneous leaching and impurity removal. The leaching liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com