Method for preparing vermiculite-based silicon-potassium fertilizer by vermiculite modification

A technology of vermiculite modification, which is applied in the field of vermiculite modification to prepare vermiculite-based silicon-potassium fertilizer, which can solve the problems of uneven silicon fertilizer products and achieve good ventilation, low production cost and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

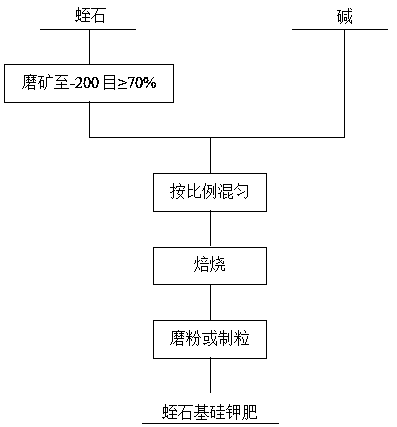

[0026] A method for preparing vermiculite-based silicon-potassium fertilizer (soil conditioner) by modifying vermiculite, such as figure 1 shown, including the following steps:

[0027] (1) Preparation of raw materials: obtain high-quality vermiculite raw materials with heavy metal ions and harmful elements not exceeding the standard through selection or beneficiation, choose a vermiculite concentrate in Henan, the ore contains SiO 2 Mass percentage content 36.48%, CaO mass percentage content 10.48%, MgO mass percentage content 14.64%, K 2 O mass percentage content 5.13%, Al 2 o 3 Mass percentage content 6.60%, Fe 2 o 3 The mass percentage content is 6.13%. After grinding, grading and dehydration, the particle size after grinding is -200 mesh, which is 80% (mass percentage), and the mass percentage of moisture after dehydration is 15%. The particle size and moisture meet the ingredients requirements;

[0028] (2) Ingredients: Weigh the vermiculite and alkali dehydrated in...

Embodiment 2

[0032] A method for preparing vermiculite-based silicon-potassium fertilizer (soil conditioner) by modifying vermiculite, comprising the following steps:

[0033] (1) Preparation of raw materials: High-quality vermiculite raw materials with heavy metal ions and harmful elements not exceeding the standard are obtained through sorting or beneficiation. In a rutile mine in Shaanxi, vermiculite is the main gangue mineral, accounting for 60% of the total mineral mass. %-70%, followed by dolomite, feldspar, chlorite, etc., using gravity separation, magnetic separation and other conventional combined processes to obtain rutile concentrate, the tailings contain SiO 2 Mass percentage content 37.34%, CaO mass percentage content 17.95%, MgO mass percentage content 10.95%, K 2 O mass percentage content 1.03%, Al 2 o 3 Mass percentage content 8.60%, Fe 2 o3 The mass percentage content is 5.82%. After grinding, grading and dehydration, the particle size after grinding is -200 mesh, which...

Embodiment 3

[0039] A method for preparing vermiculite-based silicon-potassium fertilizer (soil conditioner) by modifying vermiculite, comprising the following steps:

[0040] (1) Preparation of raw materials: High-quality vermiculite raw materials with heavy metal ions and harmful elements not exceeding the standard are obtained through sorting or beneficiation. A vermiculite concentrate in Xinjiang contains SiO 2 The mass percentage content is 36.48%, the CaO mass percentage content is 8.32%, the MgO mass percentage content is 12.37%, K 2 O mass percentage content 7.14%, Al 2 o 3 Mass percentage content 7.43%, Fe 2 o 3 The mass percentage content is 6.42%. After grinding, grading and dehydration, the particle size after grinding is -200 mesh, which is 70% (mass percentage), and the mass percentage of moisture after dehydration is 25%. The particle size and moisture meet the ingredients requirements;

[0041] (2) Ingredients: Weigh the vermiculite and alkali dehydrated in step (1) acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com