High-flame-retardance polyurethane and preparation method thereof

A polyurethane, high flame retardant technology, used in building components, building insulation materials, buildings, etc., can solve the problem of insufficient flame retardant performance of polyurethane, and achieve the effect of improving flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

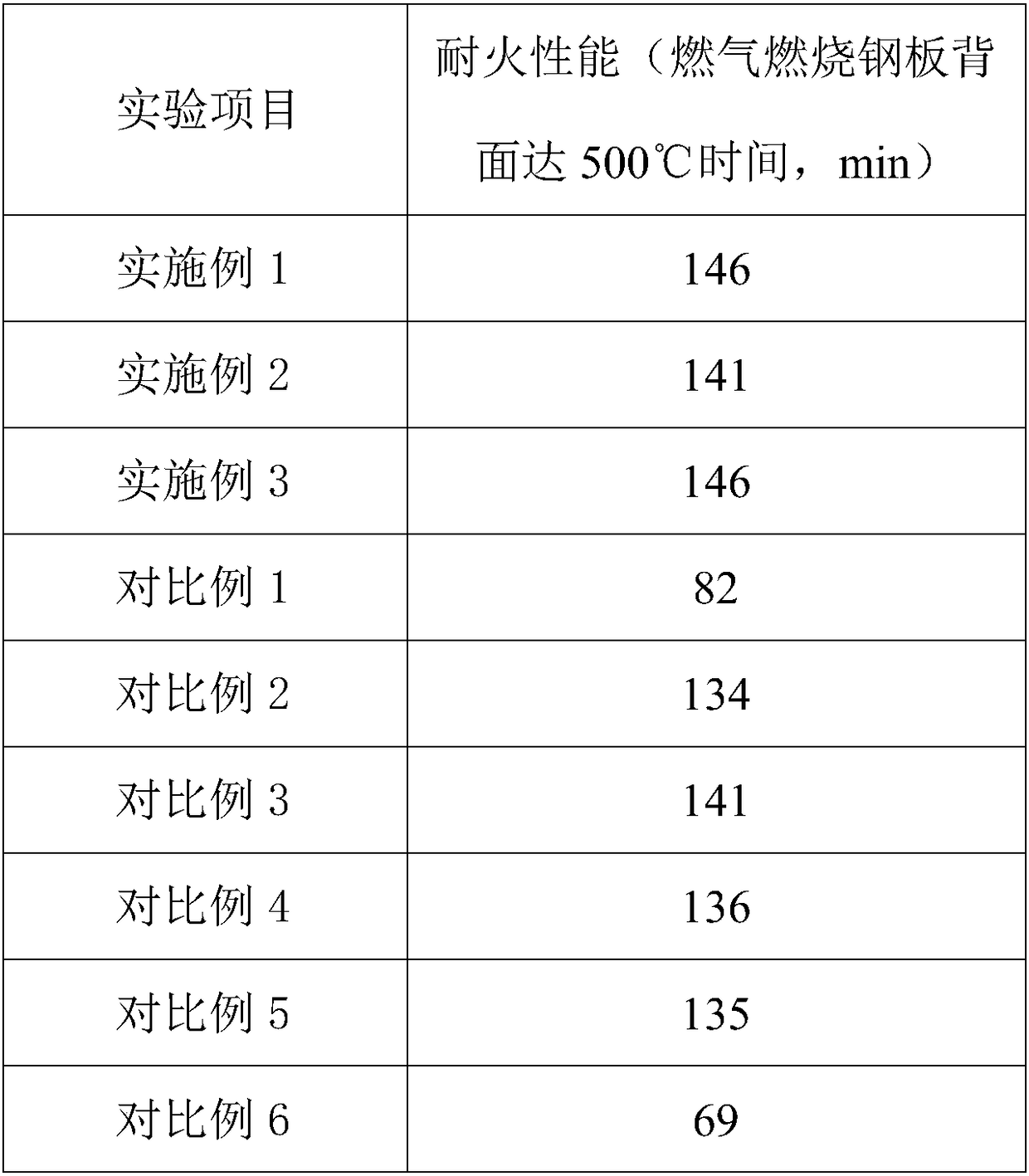

Examples

preparation example Construction

[0020] The preparation method of the polyurethane with high flame retardant performance comprises the following steps:

[0021] S1. Mix polyurethane, polycaprolactone diol, alkyd resin, polyester acrylate resin, trimethylolpropane triacrylate, polyacrylic acid, chlorinated rubber, and silicone resin evenly, at 850-1050r / Stir at min speed for 10-30min, heat up to 80-90°C, keep warm for 20-40min, then add azodicarbonamide, diethylenetriamine, benzotriazole, zinc borate, aluminum tripolyphosphate, nitrocellulose, molybdenum sodium phosphate, nano-alumina, magnesium hydroxide, chlorinated paraffin, micaceous iron oxide, hydroxypropyl silicone oil, aluminum diethylphosphinate, sodium metaborate, chlorinated paraffin, emulsified asphalt, dicumyl peroxide mixed Evenly, cool to room temperature after ball milling to obtain the base material;

[0022] S2. Mix antimony trioxide, nano-boron nitride, and flame retardant modification additives evenly, heat up to 60-80°C, keep warm for 10...

Embodiment 1

[0026] A kind of polyurethane with high flame retardancy, in parts by weight, comprising the following raw materials: 85 parts of polyurethane, 20 parts of polycaprolactone diol, 12 parts of alkyd resin, 6 parts of polyester acrylate resin, trimethylol 4 parts of propane triacrylate, 3 parts of polyacrylic acid, 4.5 parts of chlorinated rubber, 6 parts of silicone resin, 3.5 parts of azodicarbonamide, 3 parts of diethylenetriamine, 4.5 parts of benzotriazole, zinc borate 3.5 parts, 3 parts of aluminum tripolyphosphate, 3.5 parts of nitrocellulose, 3 parts of sodium molybdate, 3 parts of nano-alumina, 3.5 parts of magnesium hydroxide, 3 parts of chlorinated paraffin, 4.5 parts of mica iron oxide, 3.5 parts of hydroxypropyl silicone oil 3 parts, 3 parts of aluminum diethylphosphinate, 4.5 parts of sodium metaborate, 3.5 parts of chlorinated paraffin, 3 parts of emulsified asphalt, 6 parts of dicumyl peroxide, 4 parts of antimony trioxide, 6 parts of nano boron nitride 3 parts, 3...

Embodiment 2

[0033] A kind of polyurethane with high flame retardant performance, in parts by weight, comprising the following raw materials: 80 parts of polyurethane, 25 parts of polycaprolactone diol, 8 parts of alkyd resin, 8 parts of polyester acrylate resin, trimethylol 2 parts of propane triacrylate, 5 parts of polyacrylic acid, 3 parts of chlorinated rubber, 8 parts of silicone resin, 2 parts of azodicarbonamide, 5 parts of diethylenetriamine, 3 parts of benzotriazole, zinc borate 5 parts, 1 part of aluminum tripolyphosphate, 5 parts of nitrocellulose, 1 part of sodium molybdate, 5 parts of nano-alumina, 2 parts of magnesium hydroxide, 4 parts of chlorinated paraffin, 3 parts of mica iron oxide, 5 parts of hydroxypropyl silicone oil 1 part, 1 part of aluminum diethylphosphinate, 6 parts of sodium metaborate, 2 parts of chlorinated paraffin, 5 parts of emulsified asphalt, 3 parts of dicumyl peroxide, 5 parts of antimony trioxide, 4 parts of nano boron nitride parts, 4 parts of silane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com