A preparation method based on gold/silica core-shell microstructure and molybdenum disulfide composite thin film transistor

A technology of molybdenum disulfide and composite thin film, which is applied in the direction of transistor, semiconductor/solid-state device manufacturing, semiconductor device, etc., can solve the problems of sensitivity, limited switching frequency and speed, limited overall performance of the device, and difficulty in meeting the demand, so as to improve electrical The effect of performance, novel preparation method and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

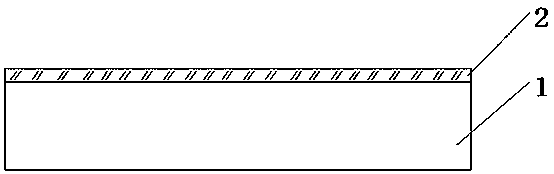

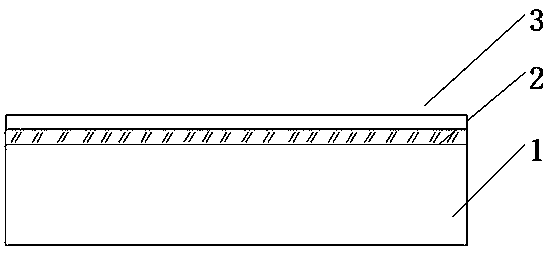

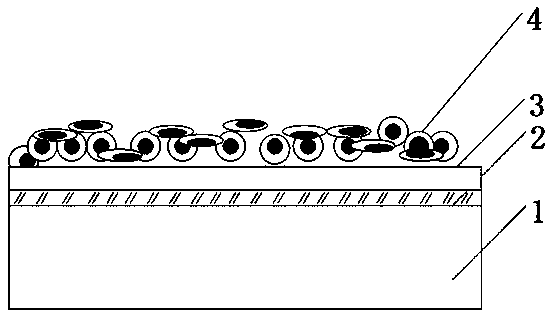

Method used

Image

Examples

Embodiment 1

[0038] (1) Prepare 0.07M ammonium tetrathiomolybdate solution, add it into a 10ml vial; measure 0.9ml of DMF and 0.1ml of ethanolamine into a 10ml vial, mix the three solutions, put the vial Put it into an ultrasonic machine for 30 minutes of ultrasonication, then put it on a magnetic stirrer and stir for about 3 hours, until the solution gradually dissolves and no obvious particles can be seen, and the molybdenum disulfide precursor solution is obtained;

[0039] (2) Measure 200ml of chloroauric acid solution with a graduated cylinder, the concentration of chloroauric acid is 0.005wt%, add it into a 500ml round bottom flask and heat and stir until boiling. Weigh 0.07g of sodium citrate (stable in air at normal temperature) and add 7ml of deionized water to make a sodium citrate solution, the concentration of the sodium citrate solution is 1wt%. Take 1.4ml of sodium citrate solution with a syringe and quickly add it to the above-mentioned flask. At this time, the temperature o...

Embodiment 2

[0046] (1) Prepare 0.1M ammonium tetrathiomolybdate solution, add it into a 10ml vial; measure 1.8ml of DMF and 0.2ml of ethanolamine into a 10ml vial, mix the three solutions, put the vial Put it into an ultrasonic machine for ultrasonication for 50 minutes, then put it on a magnetic stirrer and stir for about 5 hours, until the solution gradually dissolves and no obvious particles can be seen, and the molybdenum disulfide precursor solution is obtained;

[0047] (2) Measure 200ml of chloroauric acid solution with a graduated cylinder, the concentration of chloroauric acid is 0.01wt%, add it into a 500ml round bottom flask and heat and stir until boiling. Weigh 0.14g of sodium citrate (stable in air at room temperature) and add 14ml of deionized water to make a sodium citrate solution, the concentration of which is 1wt%. Take 1.4ml of sodium citrate solution with a syringe and quickly add it to the above-mentioned flask. At this time, the temperature of the solution is about ...

Embodiment 3

[0054] (1) Prepare 0.13M ammonium tetrathiomolybdate solution and add it into a 10ml vial; measure 0.45ml of DMF and 0.05ml of ethanolamine into a 10ml vial, mix the three solutions, put the vial Put it into an ultrasonic machine for ultrasonication for 15 minutes, then put it on a magnetic stirrer and stir for about 1.5 hours, until the solution gradually dissolves and no obvious particles can be seen, and the molybdenum disulfide precursor solution is obtained;

[0055] (2) Measure 100ml of chloroauric acid solution with a measuring cylinder, the heavy concentration of chloroauric acid is 0.015wt%, add it into a 500ml round bottom flask and heat and stir until boiling. Weigh 0.035g of sodium citrate (stable in air at room temperature) and add 3.5ml of deionized water to make a sodium citrate solution, the concentration of the sodium citrate solution is 1wt%. Take 0.7ml of sodium citrate solution with a syringe and quickly add it to the above-mentioned flask. At this time, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com