A kind of banana fiber nutrition cup and preparation method thereof

A technology of banana fiber and nutrition cup, which is applied in the direction of fiber treatment, fiber chemical characteristics, chemical method to produce bast fiber, etc., can solve the problems of increasing environmental pressure, harmful substance residue, damage to seedling root system, etc., to improve decomposition ability, improve Effect of fiber toughness and force reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

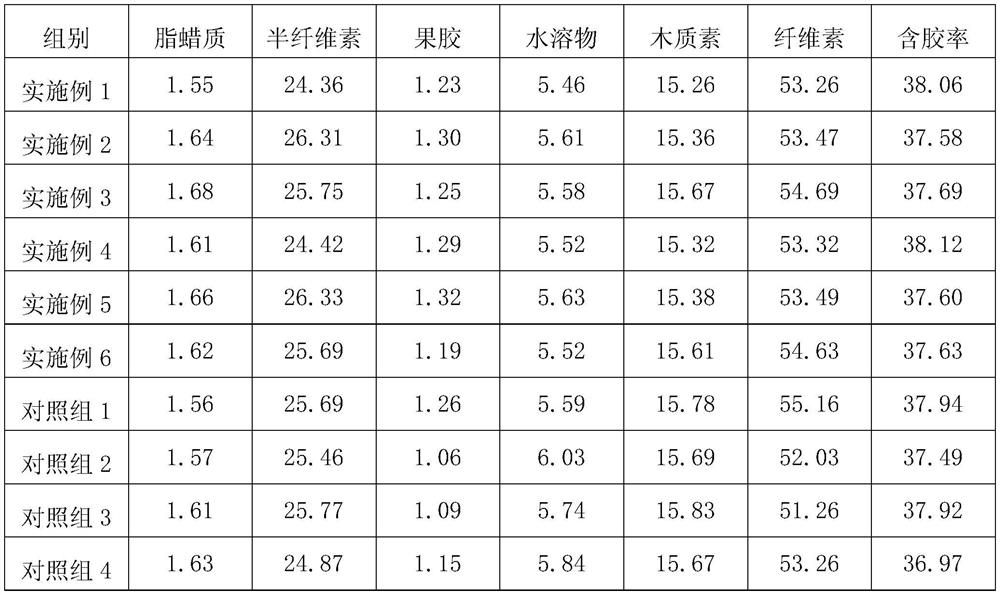

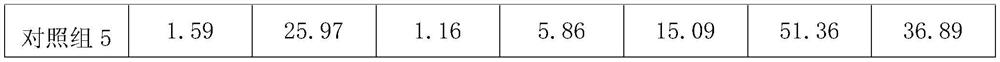

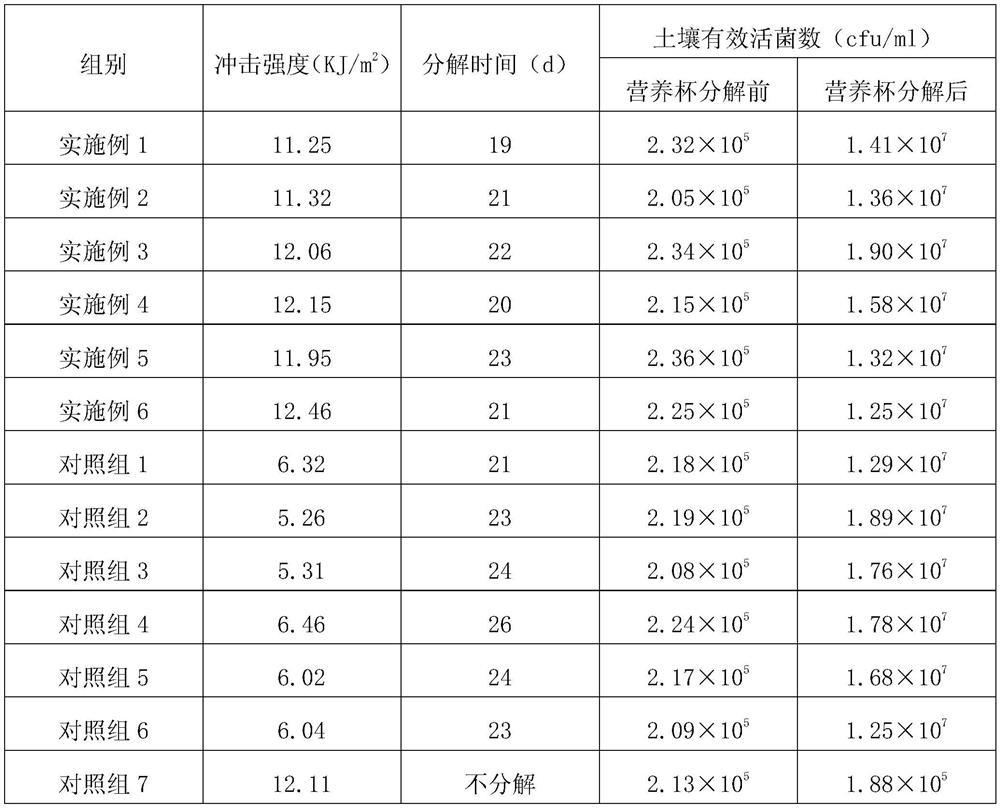

Examples

Embodiment 1

[0038] A preparation method for preparing a nutritional cup using banana fiber, the method is:

[0039] (1) prepare banana fiber:

[0040] (1) Raw material pretreatment: take the banana peel, leaves or stems and cut them into sections, and then tear the pieces into flakes with a thickness of 0.5 mm, press, scrape, and dry to obtain hemp;

[0041] (2) Degumming treatment: the hemp in step (1) is sequentially subjected to expansion treatment, oxidation treatment, acid treatment, biological enzyme treatment, enzyme inactivation treatment, dehydration, oil supply, and drying to obtain crude fiber;

[0042] The processing method of the puffing treatment is: mix the hemp with the sodium hydroxide solution whose mass concentration is 2g / L and mix according to the solid-to-liquid mass ratio of 1:17, then rapidly heat to 95°C, and boil at constant temperature for 20min, Drain the sodium hydroxide solution, remove the hemp, put it in hot water with a pressure of 7MPa and a temperature ...

Embodiment 2

[0063] A preparation method for preparing a nutritional cup using banana fiber, the method is:

[0064] (1) prepare banana fiber:

[0065] (1) Raw material pretreatment: take banana skin, leaves or stems and cut them into sections, and then tear the pieces into flakes with a thickness of 2mm, press, scrape, and dry to obtain hemp;

[0066] (2) Degumming treatment: the hemp in step (1) is sequentially subjected to expansion treatment, oxidation treatment, acid treatment, biological enzyme treatment, enzyme inactivation treatment, dehydration, oil supply, and drying to obtain crude fiber;

[0067]The processing method of the puffing treatment is: mix the hemp with the sodium hydroxide solution whose mass concentration is 4g / L and mix according to the solid-to-liquid mass ratio of 1:22, then rapidly heat to 100°C, and boil at constant temperature for 30min, Drain the sodium hydroxide solution, remove the hemp, put it in hot water with a pressure of 8MPa and a temperature of 95°C...

Embodiment 3

[0088] A preparation method for preparing a nutritional cup using banana fiber, the method is:

[0089] (1) prepare banana fiber:

[0090] (1) Raw material pretreatment: take the banana peel, leaves or stems and cut them into sections, and then tear the pieces into flakes with a thickness of 1mm, press, scrape, and dry to obtain hemp;

[0091] (2) Degumming treatment: the hemp in step (1) is sequentially subjected to expansion treatment, oxidation treatment, acid treatment, biological enzyme treatment, enzyme inactivation treatment, dehydration, oil supply, and drying to obtain crude fiber;

[0092] The processing method of the puffing treatment is as follows: mixing hemp with a sodium hydroxide solution with a mass concentration of 3g / L according to a solid-to-liquid mass ratio of 1:20, then rapidly heating to 98°C, and boiling at a constant temperature for 25 minutes, Drain the sodium hydroxide solution, remove the hemp, put it in hot water with a pressure of 7.5 MPa and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com