High-efficiency cleaner for electronic products

A technology of electronic products and cleaning agents, applied in the field of cleaning agents, can solve problems such as unsafe use, environmental pollution, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

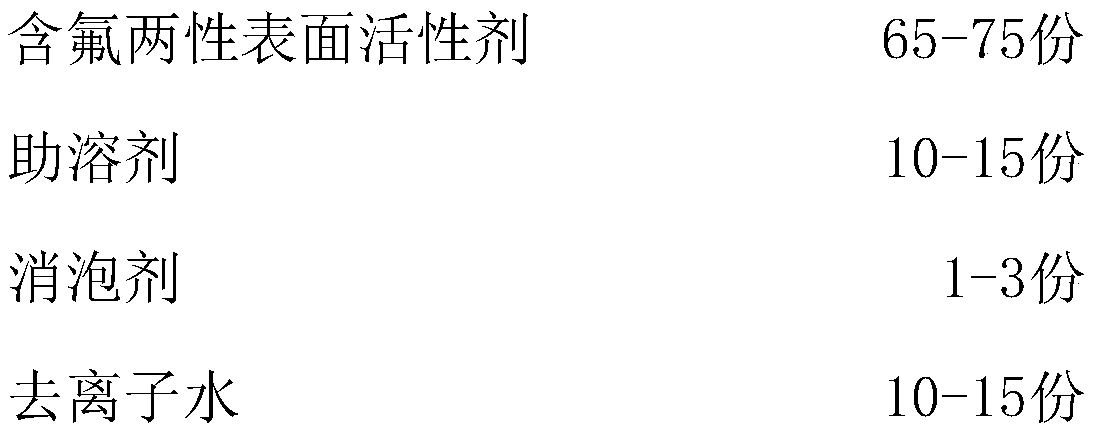

[0026] A high-efficiency cleaning agent for electronic products is made of the following raw materials in parts by weight:

[0027]

[0028] The preparation method of described fluorine-containing amphoteric surfactant, comprises the steps:

[0029] 1) Dissolve 100 g of N-tris(hydroxymethyl)methyl-2-aminoethanesulfonic acid in 400 g of acetonitrile, and add 200 g of 1-bromooctadecane therein, stir and react at 40° C. for 6 hours, and then pass Rotary steaming, washing 5 times with ether, and rotary steaming again to obtain the intermediate product;

[0030] 2) 90 g of the intermediate product prepared in step 1) was dissolved in 150 g of deionized water, and then 45 g of sodium hydroxide and 36 g of tetrabutylammonium bromide were added thereto, and stirred at room temperature for 0.5 hours, and then added 75g of perfluorodecane bromide, reflux and stir at 70°C for 1 hour, cool down after the reaction, extract with dichloromethane, wash 3 times with water, take the organic...

Embodiment 2

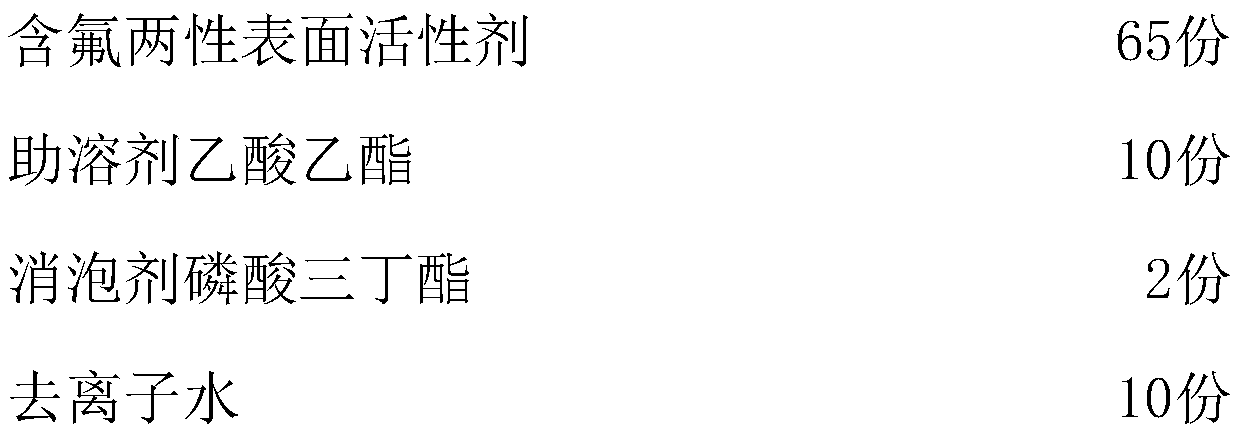

[0032] A high-efficiency cleaning agent for electronic products is made of the following raw materials in parts by weight:

[0033]

[0034] The preparation method of described fluorine-containing amphoteric surfactant, comprises the steps:

[0035] 1) Dissolve 100 g of N-tris(hydroxymethyl)methyl-2-aminoethanesulfonic acid in 500 g of ether, and add 220 g of 1-bromohexadecane to it, stir and react at 43°C for 7 hours, then pass Rotary steaming, washing with ether 6 times, rotary steaming again to obtain the intermediate product;

[0036] 2) 90 g of the intermediate product prepared in step 1) was dissolved in 160 g of deionized water, then 55 g of sodium hydroxide and 38 g of tetrabutylammonium bromide were added thereto, and stirred at room temperature for 1 hour, and then added 80g perfluorooctyl bromide, refluxed and stirred at 75°C for 17 hours, cooled after the reaction, extracted with dichloromethane, washed 4 times with water, dried the organic layer with anhydrous...

Embodiment 3

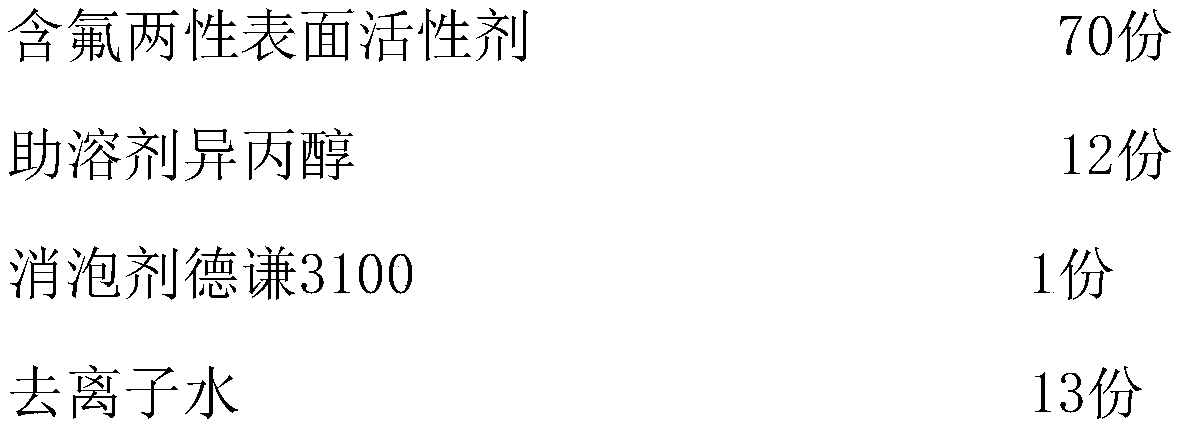

[0038] A high-efficiency cleaning agent for electronic products is made of the following raw materials in parts by weight:

[0039]

[0040] The preparation method of described fluorine-containing amphoteric surfactant, comprises the steps:

[0041] 1) 100 g of N-tris(hydroxymethyl)methyl-2-aminoethanesulfonic acid was dissolved in 550 g of ethyl acetate, and 280 g of 1-chlorohexadecane was added thereto, and the reaction was stirred at 50° C. for 7 hours, Then by rotary evaporation, washed 6 times with ether, and rotary evaporation again to obtain the intermediate product;

[0042] 2) 90 g of the intermediate product prepared in step 1) was dissolved in 170 g of deionized water, and then 49 g of sodium hydroxide and 39 g of tetrabutylammonium bromide were added thereto, and stirred at room temperature for 0.9 hours, and then added 86g perfluorodecane bromide, reflux and stir at 79°C for 19 hours, cool down after the reaction, extract with dichloromethane, wash 5 times wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com