Industrial furnace and production process for composition adjustment of smelting slags

A composition adjustment and industrial furnace technology, which is applied to the industrial furnace and production process for smelting slag composition adjustment, high-temperature molten smelting slag composition adjustment device field, can solve problems such as unevenness, rapid electrode consumption, grid pollution, etc., to achieve current Smooth voltage regulation, good production stability, and high labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

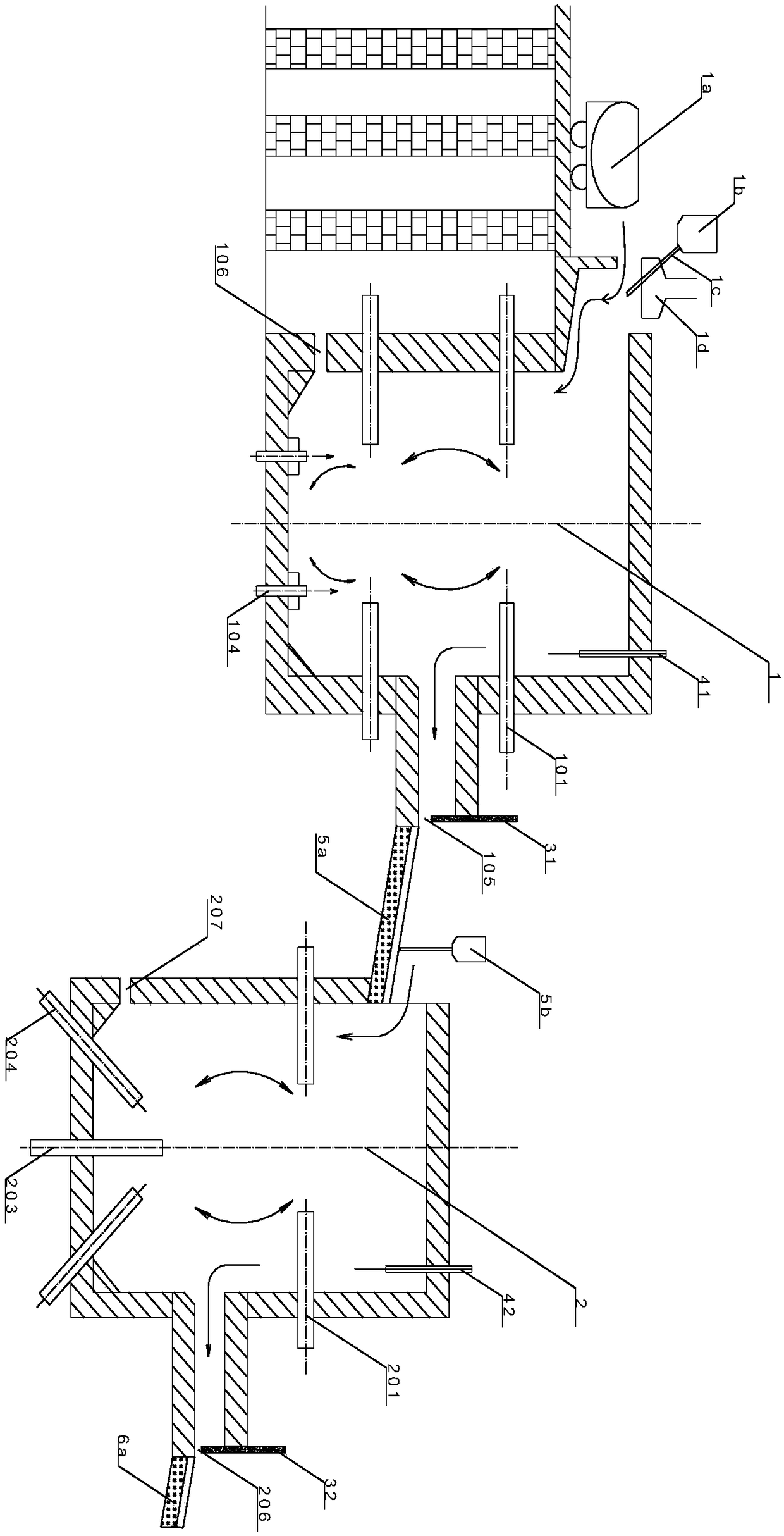

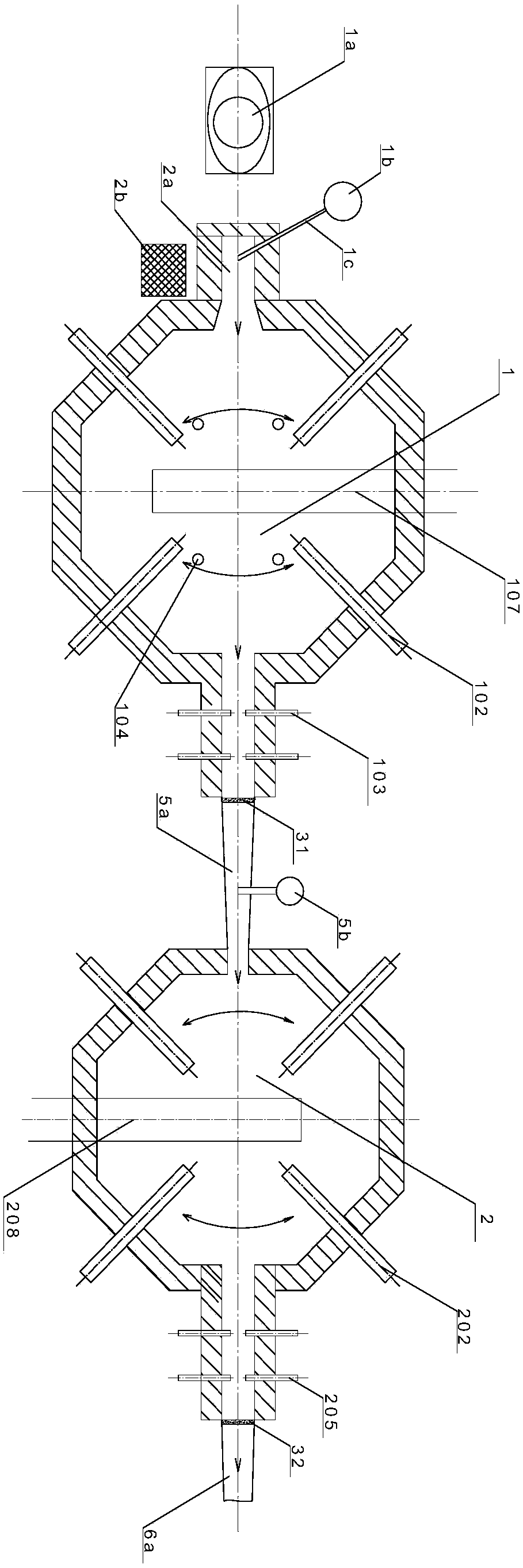

Image

Examples

Embodiment 1

[0053] Silico-manganese smelting slag is industrial waste generated in the production of silicon-manganese alloy enterprises, and 1.2-1.3 tons of silicon-manganese slag will be produced for every 1 ton of silicon-manganese alloy produced. In the silicon-manganese alloy smelting process, manganese ore, manganese-rich ore, silica and coke are mainly used as raw materials for smelting. The high-temperature slag produced in the smelting process usually becomes solid after water quenching or natural cooling in the air. The industrial furnace can directly produce a glass-ceramic plate for architectural decoration after properly adjusting the composition of the slag in a molten state. The chemical composition of silicomanganese slag is mainly composed of silicon dioxide and calcium oxide, aluminum oxide and magnesium oxide, among which CaO and SiO 2 The total content of the two > 60%, CaO / SiO 2 3 , 3~5%Na 2 CO 3, 8-10% quartz sand, 5-8% potassium feldspar, etc. can be used to prod...

Embodiment 2

[0056] Lead slag is the waste residue produced in the process of pyrometallurgy, and its main component is generally 20-30% SiO 2 , 30-40% FeO, 15-20% CaO, 5-25% ZnO. According to the chemical composition of lead slag, use 72% lead smelting slag as the main raw material, add 2-3% Glauber's salt, 15-20% quartz sand, 5-8% borax, etc. to adjust the composition, and then produce foamed microcrystalline plates with water quenching pellets. The slag composition adjustment process of this embodiment is the same as that of Example 1, the difference lies in the melting temperature and time, wherein the melting temperature of the mixing furnace is 1580 ° C, and the melting time is 8 to 10 hours; the melting temperature of the melting furnace is 1520°C, melting and homogenization time is 15-18 hours.

Embodiment 3

[0058] Ferrochrome slag is mainly chromium-containing waste slag produced during the smelting of high-carbon ferrochrome by the submerged arc furnace method, and its main component is 3-5% Cr 2 o 3 , 28-34% SiO 2 , 20-25% Al 2 o 3 , 25~30% MgO, 1~3% Fe 2 o 3 , 1-5% CaO. According to the chemical composition of ferrochrome slag, 75% ferrochrome slag is used as the main raw material, 2-3% soda ash, 10-15% quartz sand, etc. are added to adjust the composition to produce mineral insulation wool. The slag composition adjustment process of this embodiment is the same as that of Example 1, the difference lies in the melting temperature and time, wherein the melting temperature of the mixing furnace is 1490 ° C, and the melting time is 6 to 8 hours; the melting temperature of the melting furnace is 1450°C, melting and homogenization time is 8-10 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com