Preparation method and application of water-insoluble xylan

A water-insoluble xylan technology, applied in the field of food science, can solve problems that do not involve the purity of xylan, do not specify the extraction solution, and do not mention how to separate water-soluble xylan and water-insoluble xylan. Achieve high food hygiene safety, reduce intestinal effects, and good fermentability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

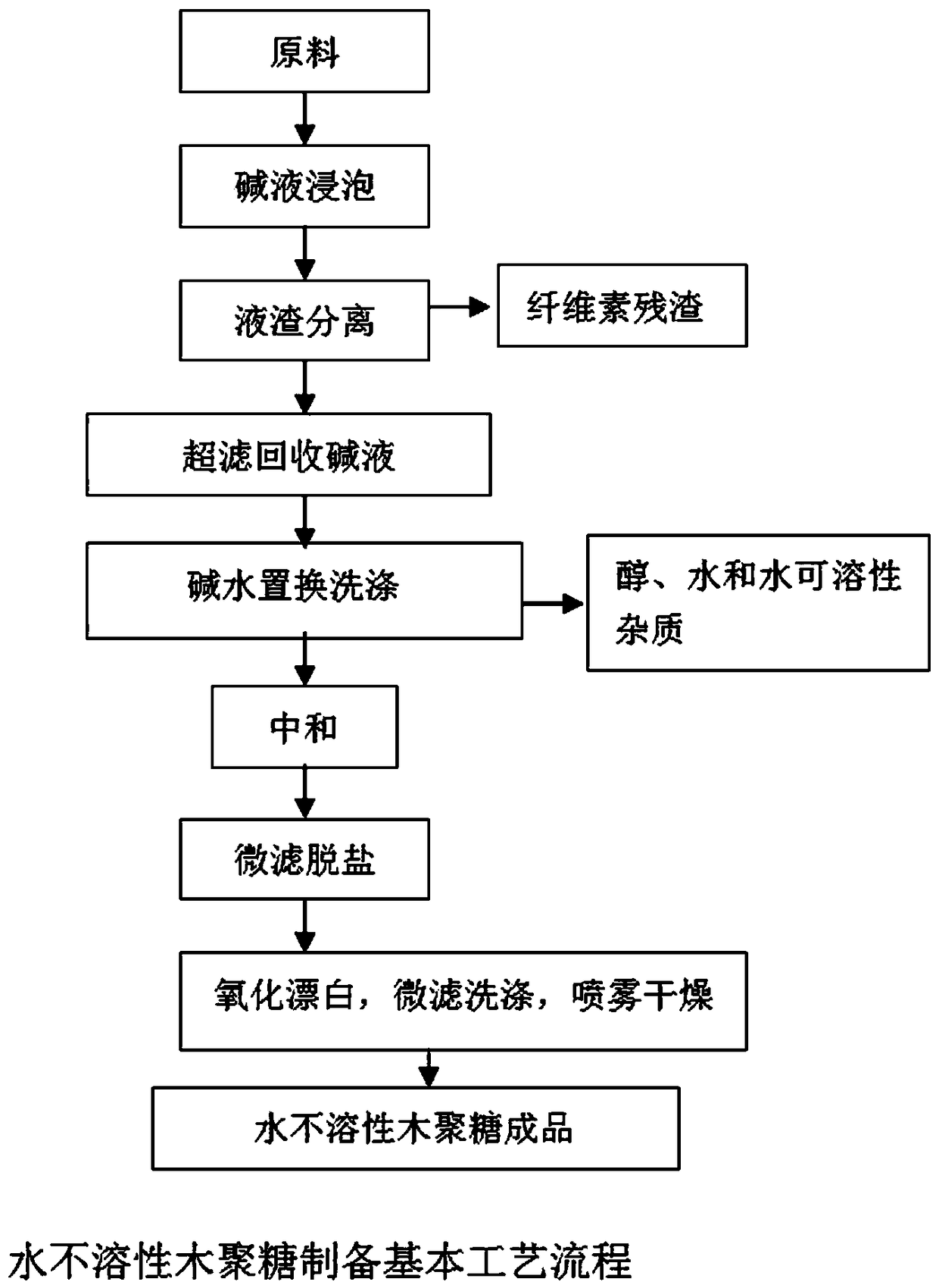

[0049] The preparation method of water-insoluble xylan comprises the following steps:

[0050] 1) Take 100 parts by weight of non-mildew and dry sugarcane straw raw materials, put them into 600 parts by weight of clean water and soak for 2 hours, use a press to remove free water, then soak the sugarcane straw raw materials again and squeeze them dry to obtain clean sugarcane The straw raw material is controlled to have a moisture content of 50%; the cleaned sugarcane straw raw material is put into 800 parts by weight of a sodium hydroxide solution with a mass concentration of 9%, mechanically ground under alkaline conditions, centrifuged and precipitated for solid-liquid Separation to obtain centrifuged residue and extract lye; the centrifuged residue is washed twice with a sodium hydroxide solution with a mass concentration of 6%, and solid-liquid separation is carried out each time;

[0051] 2) Merge three extractions of lye, and use an alkali-resistant ultrafiltration membr...

Embodiment 2

[0057] The preparation method of water-insoluble xylan comprises the following steps:

[0058]1) Take 100 parts by weight of non-mildew and dry corn stalk raw material, put it into 600 parts by weight of clean water and soak for 2 hours, use a press to remove free water, then soak the corn stalk raw material again and squeeze it dry to obtain washed corn The straw raw material is controlled to have a moisture content of 50%; the cleaned corn stalk raw material is put into 1100 parts by weight of a sodium hydroxide solution with a mass concentration of 9%, mechanically ground under alkaline conditions, centrifuged and precipitated for solid-liquid Separation to obtain centrifuged residue and extract lye; the centrifuged residue is washed twice with a sodium hydroxide solution with a mass concentration of 6%, and solid-liquid separation is carried out each time;

[0059] 2) Merge the lye extracted three times, and use an alkali-resistant ultrafiltration membrane with a molecular...

Embodiment 3

[0065] The preparation method of water-insoluble xylan comprises the following steps:

[0066] 1) Take 100 parts by weight of non-mildew and dry wheat straw raw materials, soak them in 600 parts by weight of clean water for 2 hours, use a press to remove free water, soak the raw materials of wheat straws in water again and squeeze them dry to obtain washed wheat The straw raw material is controlled to have a moisture content of 50%; the cleaned wheat straw raw material is put into 1400 parts by weight of a sodium hydroxide solution with a mass concentration of 9%, mechanically ground under alkaline conditions, centrifuged and precipitated for solid-liquid Separation to obtain centrifuged residue and extract lye; the centrifuged residue is washed twice with a sodium hydroxide solution with a mass concentration of 6%, and solid-liquid separation is carried out each time;

[0067] 2) Merge the lye extracted three times, and use an alkali-resistant ultrafiltration membrane with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com