Preparation method of perovskite solar cell based on ionic liquid additives

A technology of solar cells and perovskite, applied in the field of preparation of perovskite solar cells, can solve the problems of unfavorable production environment safety, affecting the quality of perovskite film formation, unfavorable mass production, etc., to improve the film coverage. , improve repeatability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

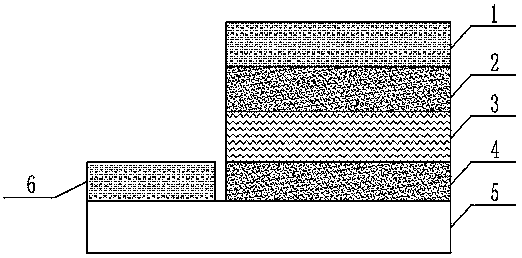

[0029] see figure 1 , spin-coated tin dioxide (SnO 2 2 ) nano solution, and annealed at 200°C for 30 minutes to prepare electron transport layer 4;

[0030] Prepare CH 3 NH 3 I and PbI 2 mixed solution of PbI 2 The concentration is 1.2 mol / L (the solvent is dimethylformamide, CH 3 NH 3 I and PbI 2 The molar ratio is 1:1), add 10wt% methylamine acetate, drop the above mixed solution on the electron transport layer 4, immediately roll coat at a constant speed (1-100 mm / s) and blow dry with nitrogen flow, at 100- Annealing at 200°C for 10 minutes to prepare the perovskite absorber layer 3;

[0031] Then spin-coat Spiro-OMeTAD (2,2',7,7'-tetrakis[N,N-bis(4-methoxyphenyl)amino]-9,9'-spirobifluorene) solution to prepare empty Cave transport layer 2;

[0032] Finally, the gold counter electrode is vapor-deposited to obtain an n-i-p type perovskite solar cell. The preparation method of the top electrode 1 and the bottom electrode 6 can adopt thermal evaporation method.

Embodiment 2

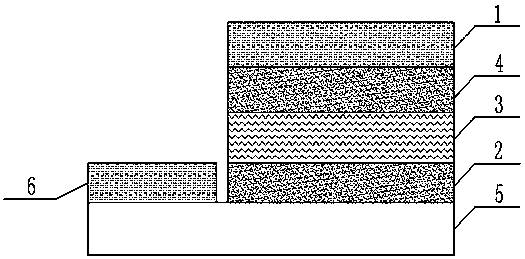

[0034] see figure 2 , Spin-coat PEDOT:PSS solution on fluorine-doped tin oxide (FTO) or tin-doped indium oxide (ITO) glass substrate (transparent conductive substrate 5) after cleaning and UV ozone treatment, at 100-200 °C Lower annealing for 15 minutes to prepare the hole transport layer 2;

[0035] Prepare CH 3 NH 3 I and PbI 2 mixed solution of PbI 2 The concentration is 1.2 mol / L (the solvent is dimethylformamide and dimethyl sulfoxide, the volume ratio is 20:1, CH 3 NH 3 I and PbI 2The molar ratio is 1:1), add the ionic liquid additive MY (MY is methylamine formate) of 10wt% of the total weight of the solution, drop the above mixed solution on the hole transport layer, and immediately roll coat at a uniform speed (1-100 mm / seconds) and blown dry with nitrogen flow, and annealed at 50°C for 20 minutes to obtain perovskite absorber layer 3;

[0036] Then spin-coat polystyrene sulfonate (such as PSSA) solution to prepare electron transport layer 4;

[0037] Finall...

Embodiment 3

[0039] Roll coating of titanium dioxide (TiO 2 ) nano solution, blown dry with nitrogen flow, and annealed at 200° C. for 30 minutes to prepare electron transport layer 4;

[0040] Prepare CH 3 NH 3 I and PbCl 2 mixed solution of PbCl 2 The concentration is 0.3 mol / L (the solvent is dimethylformamide (DMF), dimethyl sulfoxide (DMSO) and γ-butyrolactone, the volume ratio is 10:1:1, CH 3 NH 3 I and PbCl 2 The molar ratio is 3:1), add 0.1wt% ionic liquid additive MY (M is propylmethylamine salt cation, Y is formate ion) of the total weight of the solution, and directly drop-coat the above mixed solution on the electron transport layer 4 , and dried with nitrogen flow, and annealed at 100° C. for 15 minutes to obtain perovskite absorber layer 3;

[0041] Then spin-coat poly[bis(4-phenyl)(2,4,6-trimethylphenyl)amine] (PTAA) solution to prepare hole transport layer 2;

[0042] Finally, a top electrode and a bottom electrode are prepared, and the top electrode 1 and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com