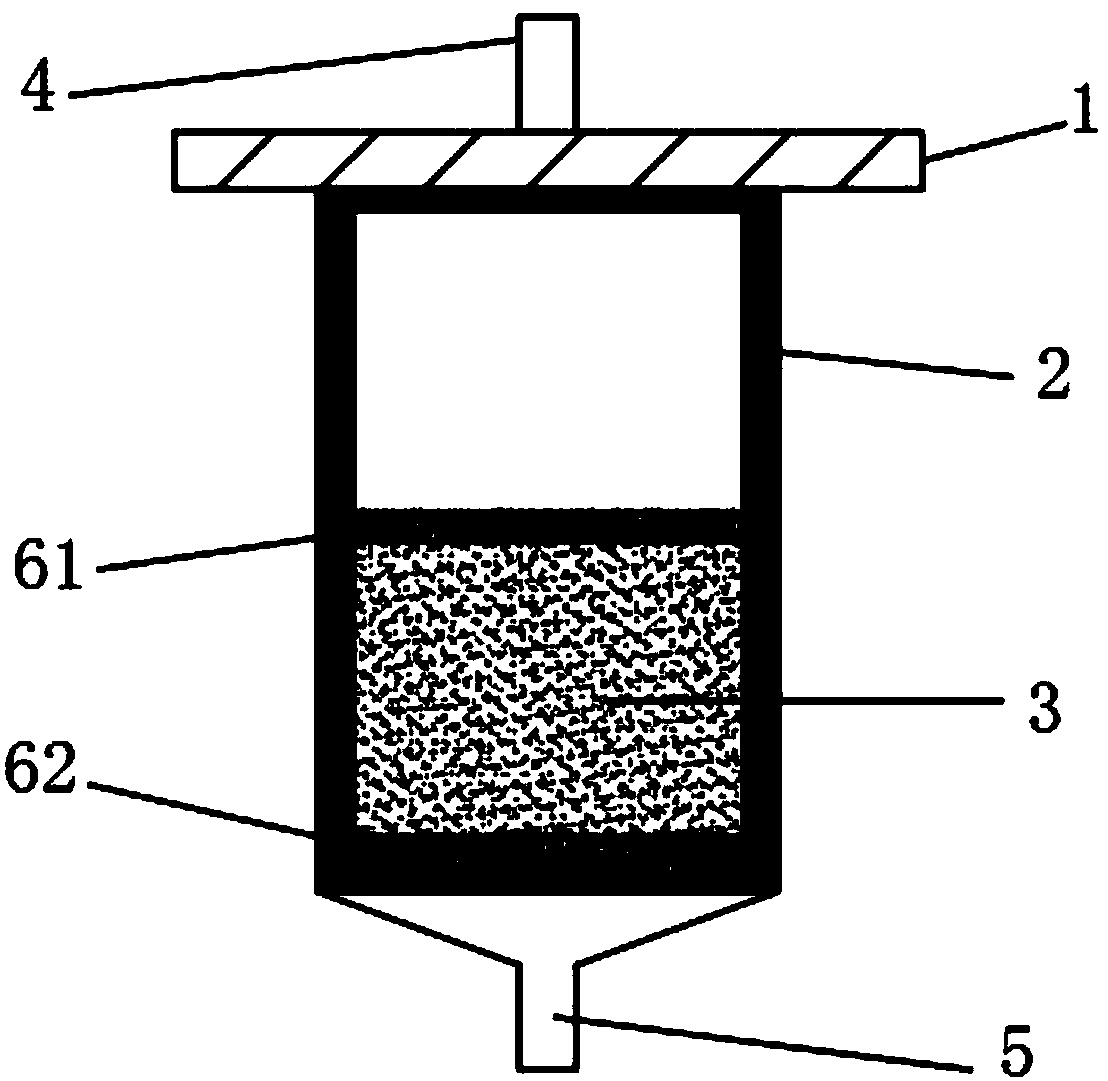

Solid-phase extraction column and solid-phase extraction column filling material production method and method for detecting aflatoxin by using solid-phase extraction column thereof

A solid-phase extraction column and aflatoxin technology, which is applied in the production of solid-phase extraction column and solid-phase extraction column packing, and in the field of detection of aflatoxin, can solve problems such as false positives, high detection costs, and cumbersome processing operations, and achieve Good reproducibility and stability, low detection cost, and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of solid phase extraction packing:

[0031] 1. Carrier synthesis: Add 75g of distilled water and 1g of polyvinyl alcohol powder into a 250ml three-neck flask, stir and dissolve them well as the dispersed phase for later use. Precisely measure 15g of toluene, 5g of n-octane, 9g of N-vinylpyrrolidone and 15g of divinylbenzene into a small beaker, add 0.15g of azobisisobutyronitrile and mix well, then pour into a three-necked flask, stir rapidly for 30min, and heat to 70 ℃ condensed and refluxed, stirred and reacted at 1000r / min for 12h, then stopped the reaction, washed the product with water and methanol, and dried it in vacuum at 80°C for 4h to obtain divinylbenzene-N-vinylpyrrolidone copolymer microspheres. The spherical particle size is 30-50μm.

[0032] 2. Synthesis of ionic liquid: Weigh 25g of N-methylimidazole and 26g of 1-chloro-n-octane in a 100mL flask, heat to reflux for 10h, wash the reacted liquid with hot ethyl acetate several times,...

Embodiment 2

[0039] The preparation method of solid phase extraction packing:

[0040] 1. Carrier synthesis: Add 70 g of distilled water and 1 g of polyvinyl alcohol powder into a 250 ml three-neck flask and stir to dissolve them as a dispersed phase for later use. Precisely measure 15g of toluene, 5g of n-octane, 9g of N-vinylpyrrolidone and 15g of divinylbenzene into a small beaker, add 0.15g of azobisisobutyronitrile and mix well, then pour into a three-necked flask, stir rapidly for 25min, and heat to 65 ℃ reflux, stirring and reacting at 1000r / min for 11.5h, then stop the reaction, wash the product with water and methanol, and dry it in vacuum at 75°C for 3.5h to obtain divinylbenzene-N-vinylpyrrolidone copolymer microspheres. The particle size of the microspheres is 30-50 μm.

[0041] 2. Synthesis of ionic liquid: Weigh 25g of N-methylimidazole and 26g of 1-chloro-n-octane in a 100mL flask, heat to reflux for 10h, wash the reacted liquid with hot ethyl acetate several times, discard...

Embodiment 3

[0049] The preparation method of solid phase extraction packing:

[0050] 1. Carrier synthesis: Add 80 g of distilled water and 1 g of polyvinyl alcohol powder into a 250 ml three-necked flask and stir to dissolve them as a dispersed phase for later use. Precisely measure 15g of toluene, 5g of n-octane, 9g of N-vinylpyrrolidone and 15g of divinylbenzene into a small beaker, add 0.15g of azobisisobutyronitrile and mix well, then pour into a three-necked flask, stir rapidly for 35min, and heat to 75 ℃ condensed and refluxed, stirred and reacted at 1000r / min for 12.5h, then stopped the reaction, washed the product with water and methanol, and dried in vacuum at 85°C for 4.5h to obtain divinylbenzene-N-vinylpyrrolidone copolymer microspheres. The particle size of the microspheres is 30-50 μm.

[0051] 2. Synthesis of ionic liquid: Weigh 25g of N-methylimidazole and 26g of 1-chloro-n-octane in a 100mL flask, heat to reflux for 10h, wash the reacted liquid with hot ethyl acetate se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com