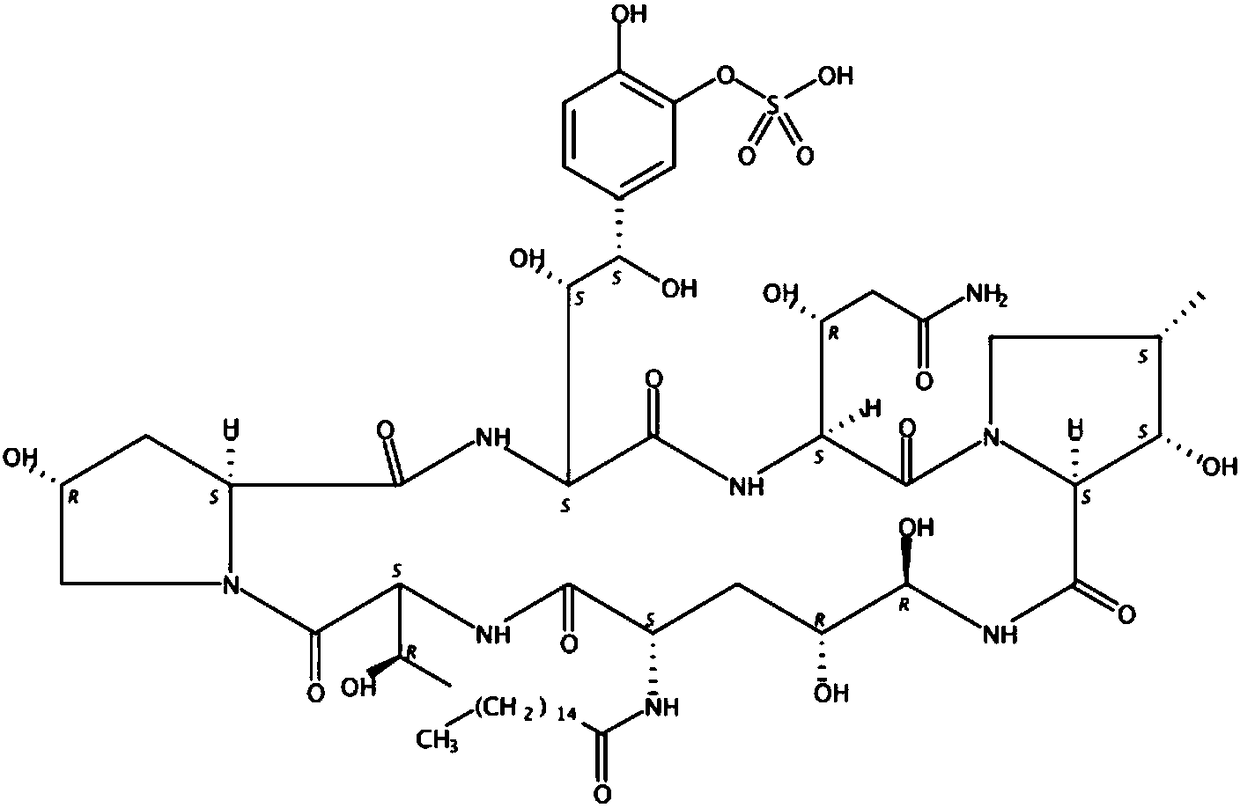

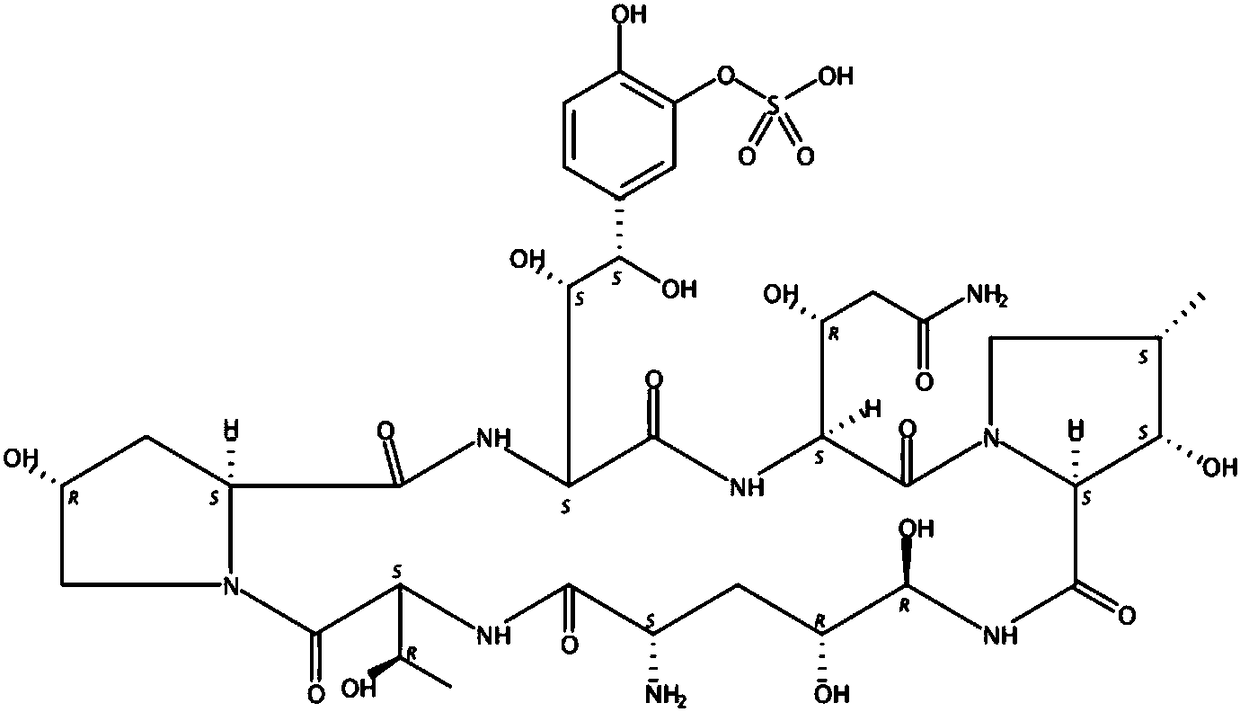

Fermentation method of micafungin sodium precursor FR179642

A polymer and cross-linking enzyme technology, applied in the direction of fermentation, peptide, etc., can solve the problems of complicated separation and purification steps, slow conversion speed, poor stability, etc., and achieve the effect of simple operation, avoiding inactivation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 produces the fermentation of deacylase bacterial strain and crude enzyme preparation

[0036] Bacterial species: Streptomyces albus (Streptomyces albus), preservation number: ATCC21725; -80°C cryopreservation tube;

[0037] Seed medium: 0.5% hot-fried soybean cake powder (w / v, the same below), 0.5% yeast powder, 0.5% peptone, 1% glucose, pH about 6.8-7.2, cultured at 30°C for 1-2 days;

[0038] Fermentation medium: hot fried soybean cake powder 1%, yeast powder 1%, peptone 1%, glucose 3%, sodium chloride 0.5%, magnesium sulfate heptahydrate 0.2%, dipotassium hydrogen phosphate 0.1%, pH about 6.8-7.2 , cultured at 30°C for 2 to 3 days;

[0039] Inoculate the genetically engineered strain of Streptomyces albicans on the seed medium, culture at 30°C for 1-2 days, then inoculate 5% of the fermentation volume into the fermentation medium, and cultivate at 30°C for 2-3 days;

[0040] After the fermentation is completed, filter the fermented liquid to obtain the...

Embodiment 2

[0041] Embodiment 2 Preparation of FR901379

[0042] Coleophoma empetri strains were grown in seed medium. The seed culture medium is glucose 10g / L, soluble starch 30g / L, cottonseed cake powder 20g / L, dry corn steep liquor 5g / L, dipotassium hydrogen phosphate 2g / L, calcium carbonate 3g / L, defoamer 1g / L.

[0043] Prepare an appropriate amount of seed medium, sterilize at 120°C for 30 minutes, cool to 24-26°C, insert 48h seed-age shake flask seeds at an inoculum volume ratio of 0.5-1% of the seed medium volume, and then culture at 24-26°C for 48h .

[0044] Transfer the cultured seeds to 12000L fermentation medium at 120°C for 30 minutes and cool to 24-26°C at a ratio of 2%. The composition of the fermentation medium is as follows: fructose 140. Corn gluten powder 10, casein 6, yeast peptone 7, magnesium sulfate 2, dipotassium hydrogen phosphate 0.5, calcium carbonate 3, defoamer 0.5, and the rest is water.

[0045] During the fermentation process, the temperature is 24-26°...

Embodiment 3

[0047] Example 3 Deacylase cross-linking conversion to produce micafungin core

[0048] Prepare 1000 L of phosphate buffer solution in the reaction tank, containing 2.24 g / L of potassium dihydrogen phosphate and 1.24 g / L of disodium hydrogen phosphate, and adjust the pH to 6.0 with hydrochloric acid or sodium hydroxide.

[0049] Add 20 kg of crude enzyme and 2 kg of bovine serum albumin (BSA) to the phosphate buffer, feed air at a flow rate of 200 L per minute, stir for 30 minutes at a stirring speed of 80 rpm, and stand at 8° C. for 1 hour.

[0050] Add 20 mmol / L of glutaraldehyde to the reaction solution, stir at 30° C. for 2 hours, and the stirring speed is 100 rpm.

[0051] Add 20kg of micafungin precursor FR901379 to the reaction solution, stir and react at 30°C for 6-24 hours, the stirring speed is 100rpm, and monitor the micafungin precursor FR901379 and micafungin in the conversion system by HPLC during the conversion process Mother nucleus concentration, when the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com