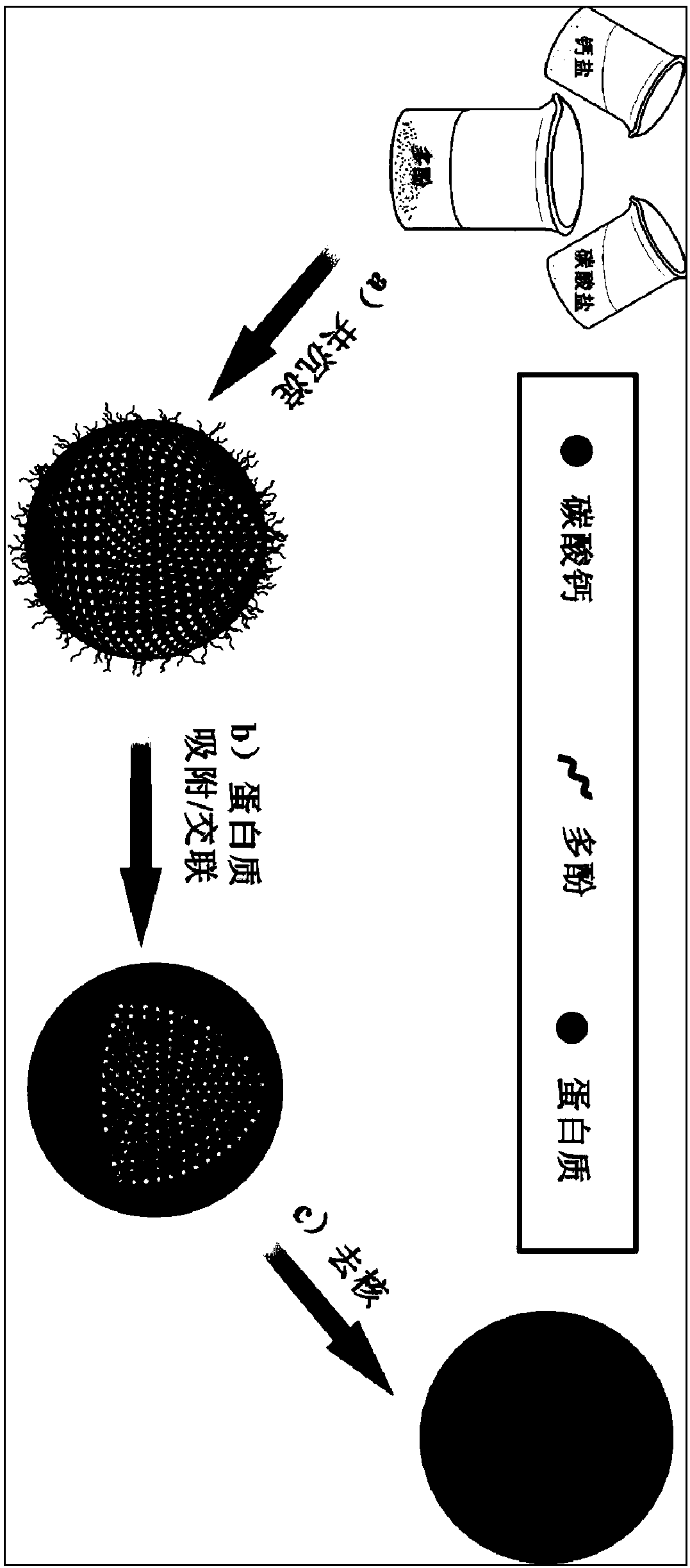

One-step adsorption method used for preparing protein microcapsules

A protein and microcapsule technology, applied in the preparation of protein microcapsules, refers to the field of protein microcapsules prepared by one-step adsorption method, which can solve the problems of cumbersome operation steps, difficult process, high loss, etc., and achieve simple preparation process, mild conditions, Good universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] At 25°C, stir 1mL of 1M calcium chloride solution and 2mL of 2.5mg / mL tannic acid solution evenly, adjust the rotation speed to 1200 rpm, and quickly add 3mL of 0.33M sodium carbonate solution , stirred for 30 s, stood still for 10 min, centrifuged, and washed three times with ultrapure water to obtain tannin-doped calcium carbonate particles.

[0037] Dry the collected tannic acid-doped calcium carbonate particles in an oven at 60°C overnight, and observe the particle morphology with a scanning electron microscope (FESEM, SU8010 HITACHI, the same below), see figure 2 shown.

[0038] Put the collected particles into a centrifuge tube, add 15mL bovine serum albumin solution with a concentration of 20mg / mL, adjust the pH of the buffer solution to 9.5, incubate at 20°C for 2 hours, centrifuge, wash with the buffer solution, and redisperse in In a centrifuge tube, add 10 mL of 4-(4,6-dimethoxytriazin-2-yl)-4-methylmorpholine hydrochloride solution with a concentration of 60...

Embodiment 2

[0041] At 15°C, mix 1mL of calcium nitrate solution with a concentration of 0.1M and 2mL of a solution of epigallocatechin gallate with a concentration of 2mg / mL, stir evenly, adjust the speed to 450 rpm, and quickly add 3mL of It is a 0.033M potassium carbonate solution, stirred for 35s, allowed to stand for 10min, centrifuged, and washed three times with ultrapure water to obtain epigallocatechin gallate-doped calcium carbonate particles.

[0042] Put the particles in a centrifuge tube, add 20mL of thyroglobulin solution with a concentration of 0.1mg / mL, adjust the pH of the buffer solution to 7.0, incubate at 25°C for 6 hours, centrifuge, wash with the buffer solution, and redisperse in the centrifuge tube Add 10 mL of 4-(4,6-dimethoxytriazin-2-yl)-4-methylmorpholine hydrochloride solution with a concentration of 20 mg / mL, incubate for 6 hours, centrifuge, and wash with ultrapure water three times.

[0043] Immerse with 0.01M hydrochloric acid for 5 hours, centrifuge, and ...

Embodiment 3

[0045] At 20°C, mix 1mL of 0.33M calcium chloride and 2mL of 10mg / mL tannic acid solution, stir evenly, adjust the ultrasonic frequency to 20kHz, and quickly add 3mL of 0.33M ammonium bicarbonate solution , ultrasonically shaked for 40 s, allowed to stand for 20 min, centrifuged, and washed with ultrapure water three times to obtain tannic acid-doped calcium carbonate particles.

[0046] Put the collected particles into a centrifuge tube, add 20mL of gelatin solution with a concentration of 10mg / mL, adjust the pH of the buffer solution to 8.0, incubate at 15°C for 4 hours, centrifuge, wash with the buffer solution, and redisperse in the centrifuge tube , add 80 mL of 4-(4,6-dimethoxytriazin-2-yl)-4-methylmorpholine hydrochloride solution with a concentration of 5 mg / mL, incubate for 2 hours, centrifuge, and wash with ultrapure water three times .

[0047] Immerse with 0.05M hydrochloric acid for 5 hours, centrifuge, and wash with ultrapure water to obtain gelatin microcapsule...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com