A kind of treatment method of cephalosporin antibiotic production wastewater

A technology for producing wastewater and treatment methods, which is applied in water/sewage treatment, water treatment parameter control, water/sewage multi-stage treatment, etc., can solve the problems of increasing treatment difficulty, iron-carbon fillers prone to hardening, and reduced crystallization efficiency, etc. Achieve the effect of avoiding sulfate accumulation, prolonging operation stability, and reducing the amount of condensed water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

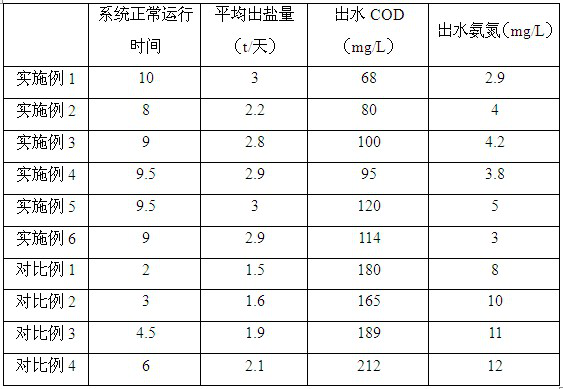

Examples

Embodiment 1

[0029] Processing method of the present invention comprises the following steps:

[0030] 1) Filtration: The raw water is filtered by the basket filter under the action of the raw water delivery pump and then enters the ultrafiltration device. The ultrafiltration device includes four ultrafilters connected in parallel to remove suspended solids and macromolecular organic matter in the raw water. The external pressure hollow fiber membrane is used in the ultrafiltration;

[0031] 2) Electrodialysis: Ultrafiltration effluent enters the first-level concentrated water tank and the first-level fresh water tank of the first-level electrodialysis to make up the liquid level, and the concentrated water of the first-level concentrated water tank and the fresh water of the first-level fresh water tank are transported through the pipeline To the inlet of the concentration chamber and the desalination chamber of the first-stage electrodialysis, set the voltage at 190~240V, and separate th...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that: when the conductivity detector at the outlet of the first-stage electrodialysis concentrated water detects that the conductance of the concentrated water is higher than 160ms / cm, the concentrated concentrated water enters the concentrated concentrated water tank and then enters the MVR; When the conductivity detector at the fresh water outlet of the secondary electrodialysis detects that the conductivity of the fresh water is less than 6ms / cm, the fresh water enters the biochemical system.

Embodiment 3

[0037] The difference between this embodiment and embodiment 1 is that ammonia water is added to the concentrated concentrated water tank to adjust its pH to 6-7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com