Lithium-rich material/conductive organic polymer composite positive material and electrode preparation method

A technology of composite cathode materials and lithium-rich cathode materials, which is applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc. and other problems, to achieve the effect of improving electron transfer rate, short diffusion path, and improving conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of lithium-rich cathode materials:

[0044] The lithium acetate of stoichiometric ratio, manganese acetate, cobalt acetate, nickel acetate are dissolved in the ethanol solution of 50%, obtain the metal ion concentration and be the mixed solution A of 2mol / L, oxalic acid is dissolved in the ethanol solution of 99.5%, obtain The concentration of oxalic acid is 2mol / L mixed solution B. Add the mixed solution A dropwise to the mixed solution B, stir at 60°C for 1 hour, transfer to a polytetrafluoroethylene hydrothermal kettle, then seal the reaction kettle and place it in an oven, and react at a constant temperature of 180°C for 12 hours. Dry at 80°C for 12h under vacuum, calcinate at 450°C for 6h in a muffle furnace, then calcinate at 500°C for 5h, 750°C for 2h, and 900°C for 12h in an air atmosphere in a tube furnace, then quench with liquid nitrogen to room temperature. Obtain nano / micro rod-like hierarchical structure lithium-rich layered oxide cathode ...

Embodiment 2

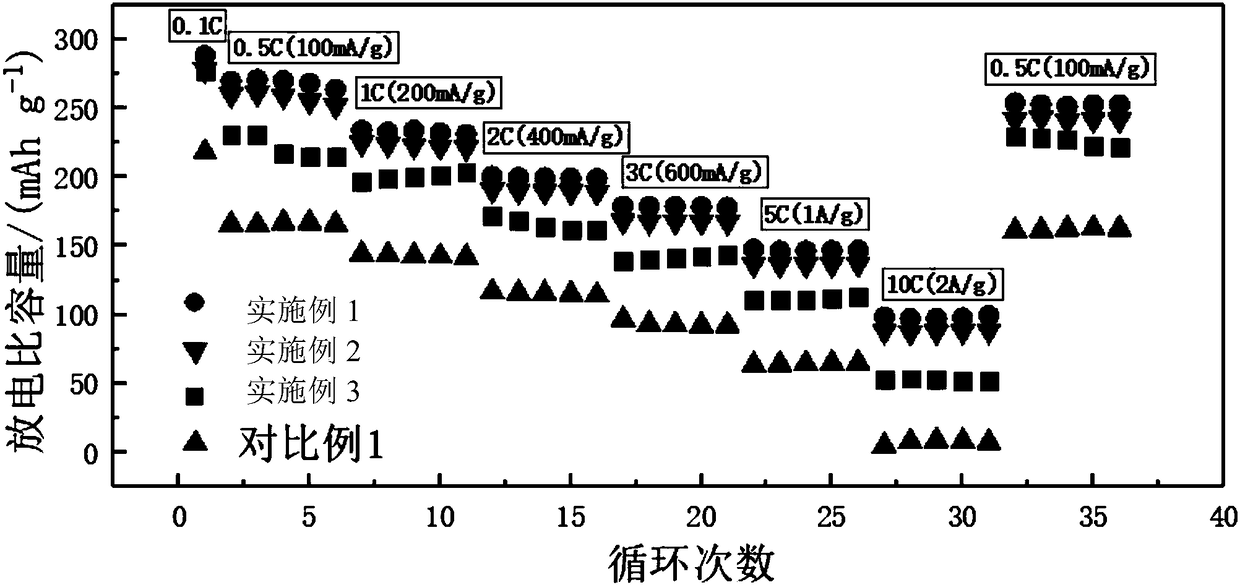

[0055] The preparation method of embodiment 2 is the same as embodiment 1, and the only difference is that lithium acetate of stoichiometric ratio, manganese acetate, cobalt acetate, nickel acetate are dissolved in the ethanol solution of 70% instead of being dissolved in the ethanol solution of 50%. The rate performance test results are as follows: figure 1 shown.

Embodiment 3

[0057] The preparation method of Example 3 is the same as that of Example 1, the only difference is that the above-mentioned lithium-rich positive electrode material and conductive cross-linked polymer are dissolved in chloroform at a mass ratio of 90:10 instead of being dissolved in chloroform at a mass ratio of 85:15. in chloroform. The rate performance test results are as follows: figure 1 As shown, compared with the sol-gel method, adopting the method of the present invention to synthesize the lithium-rich positive electrode material has higher rate performance; in the process of preparing the lithium-rich positive electrode material, 50% ethanol solution is used, and the lithium-rich positive electrode material and the conductive cross-linked polymer The in-situ coating ratio performance is the best with the mass ratio of 90:10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com