Preparation method of lithium-sulfur battery positive electrode material

A cathode material, lithium-sulfur battery technology, applied in battery electrodes, lithium storage batteries, nanotechnology for materials and surface science, etc., can solve the problems of material structure collapse, volume expansion, agglomeration, etc., to reduce agglomeration phenomenon, inhibit Effect of crystal aging and conductivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

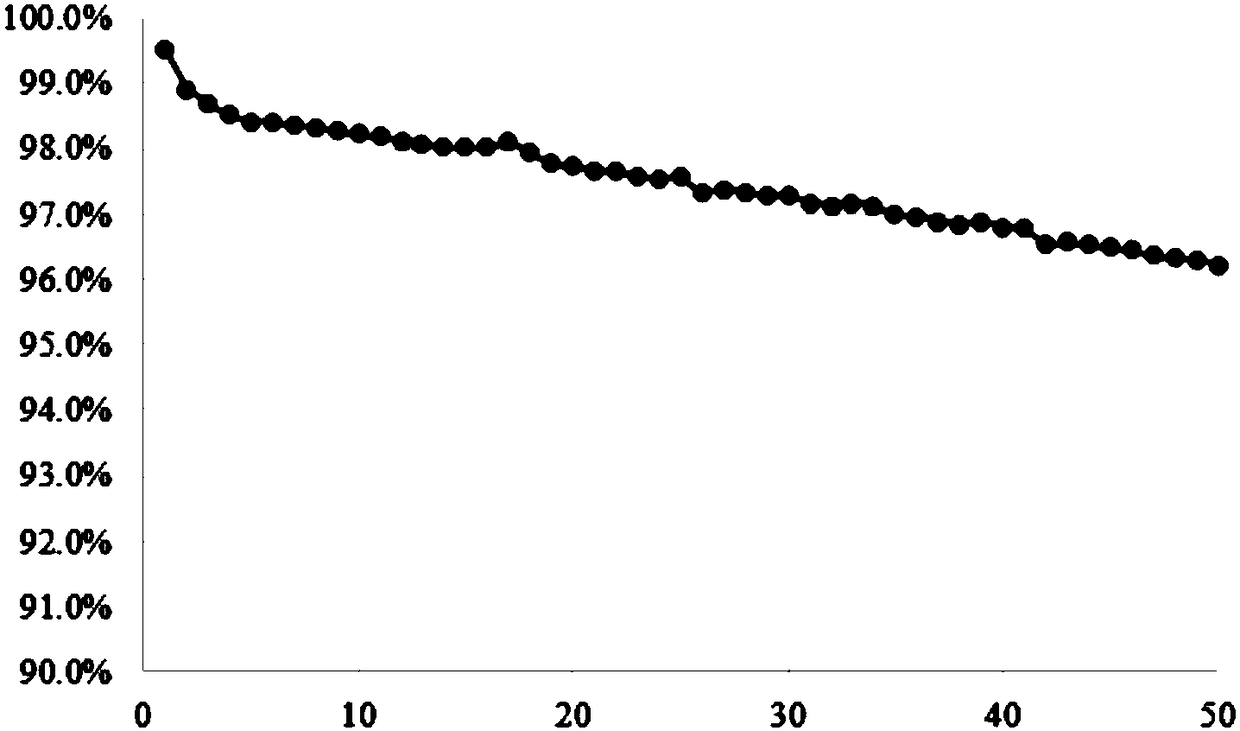

Image

Examples

Embodiment 1

[0025] Conductive polymer monomer solution: Take an appropriate amount of aniline monomer and add it to ethanol solvent, stir rapidly, ultrasonically oscillate, and control the temperature at about 25°C. During the stirring and mixing process, a uniform mixed solution is formed to obtain a concentration of 0.05g / mL The ethanol solution of aniline monomer, standby;

[0026]Polysulfide organic solution: select raw materials according to the raw material ratio of polysulfide organic solution, specifically: take 0.28g flake lithium powder and 5.12g sulfur element, and put them into 1,3 -In a mixed organic solvent of dioxolane and ethylene glycol dimethyl ether (volume ratio 3:1), then, under the constant temperature condition of 60°C, the temperature was controlled and stirred for 48 hours. After the reaction was completed, filter and adjust The amount of solvent, obtains 0.2mol / L maroon lithium polysulfide organic solution, standby;

[0027] Sulfur / conductive polymer composite m...

Embodiment 2

[0031] Conductive polymer monomer solution: Take an appropriate amount of 3,4-ethylenedioxythiophene monomer and add it to n-propanol solvent, stir rapidly and ultrasonically, and control the temperature at about 40°C during the stirring and mixing process to form a uniform mixture to obtain a n-propanol solution of 3,4-ethylenedioxythiophene monomer with a concentration of 0.08g / mL for subsequent use;

[0032] Polysulfide organic solution: select raw materials according to the raw material ratio of polysulfide organic solution, specifically: take 0.28g of powdered lithium powder and 6.4g of sulfur element, and put them into carbitol solvent under the protection of nitrogen , then, control the temperature at 100°C, and carry out the stirring reaction for 12 hours. After the reaction, filter and adjust the amount of solvent, so that a 0.2mol / L maroon lithium polysulfide organic solution is obtained, and set aside;

[0033] Sulfur / conductive polymer composite material: Take 20ml...

Embodiment 3

[0036] Conductive polymer monomer solution: Take an appropriate amount of thiophene monomer and add it to tetrahydrofuran solvent, stir rapidly and ultrasonically, control the temperature at about 35°C during the stirring and mixing process, and form a uniform mixed solution, and prepare a concentration of 1g / mL thiophene Monomer tetrahydrofuran solution, standby;

[0037] Polysulfide organic solution: select raw materials according to the raw material ratio of polysulfide organic solution, specifically: take 22.4g of powdered potassium powder and 6.4g of sulfur element, and put them into ethylene carbonate solvent under the protection of nitrogen In, then, control the temperature at a temperature of 50° C., and carry out stirring reaction for 24 hours. After the reaction is completed, filter, adjust the amount of solvent, and prepare a ethylene carbonate solution to obtain 3.0 mol / L potassium polysulfide for subsequent use. ;

[0038] Sulfur / conductive polymer composite mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com