Capacitor type nickel-hydrogen power battery and preparation method thereof

A power battery and capacitive technology, applied in the direction of nickel storage battery, battery electrode, alkaline storage battery, etc., can solve the problems of increased conductivity, low rate performance, low conductivity, etc., achieve low temperature performance, long life, and improve rate performance , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

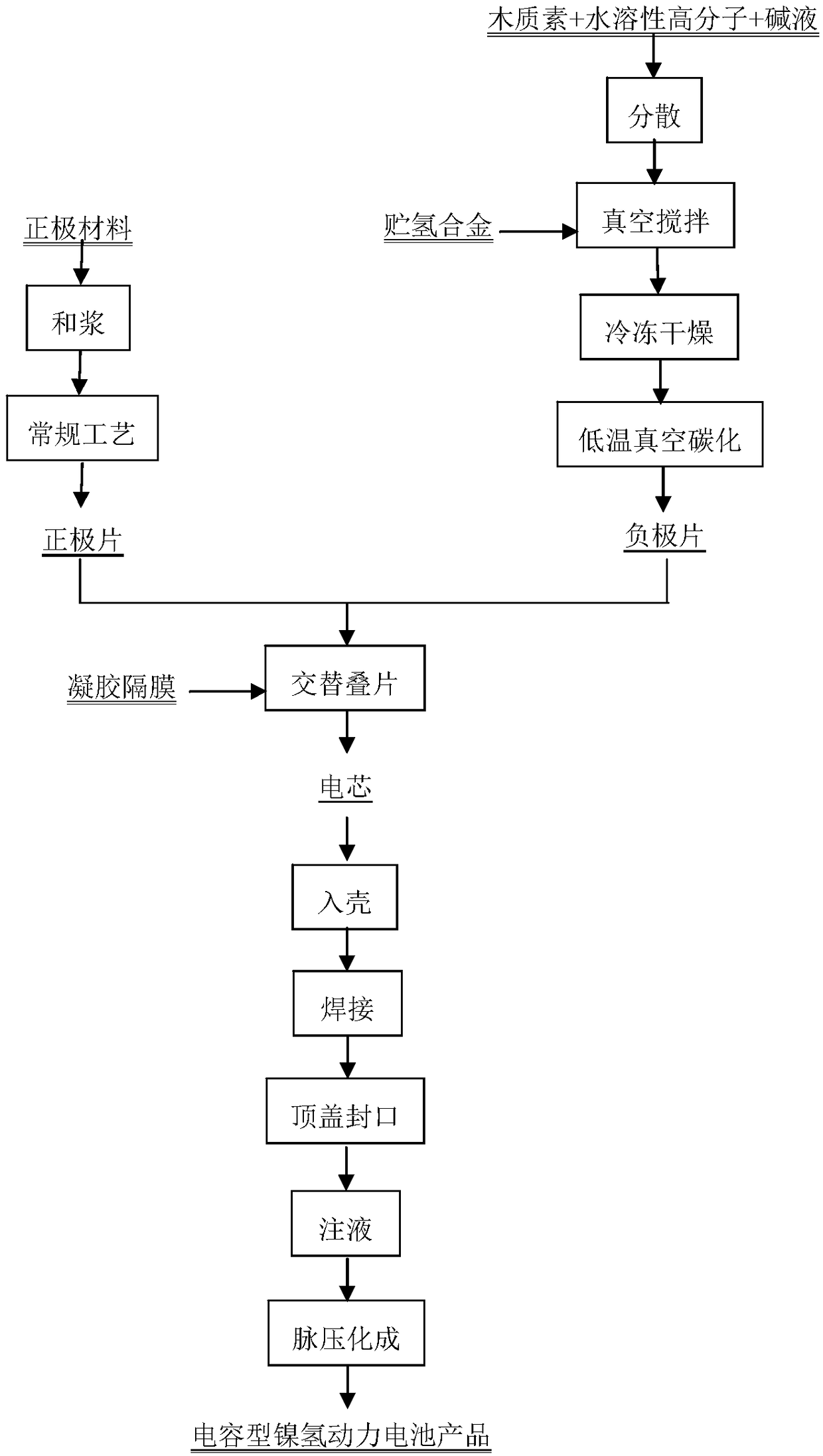

[0037] The preparation method of capacitive nickel-metal hydride power battery comprises the steps:

[0038] a. Prepare positive electrode battery slurry, and make positive electrode sheet by conventional wet process;

[0039] b. The negative electrode configuration is that the mass ratio of zinc oxide and sodium hydroxide is 1:10, and it is first configured with pure water to form a solution with a concentration of sodium hydroxide of 2mol / L, according to the mass ratio of zinc oxide, sodium hydroxide and lignin powder 1:15, add lignin, after high-speed dispersion, then add 20% polyacrylamide of lignin mass, stir in vacuum to form a solution; then add 1500% lignin mass of AB 5 Hydrogen storage alloy, after stirring evenly, vacuum defoaming into slurry. A separator made of alumina and nickel foam with lugs were inserted into the fixing tank, and then the slurry was poured into the fixing tank, and then dried in a vacuum freeze dryer at -50°C for 24 hours. Finally, in a vacuu...

Embodiment 2

[0044] The preparation method of capacitive nickel-metal hydride power battery comprises the steps:

[0045] a. Prepare positive electrode battery slurry, and use conventional sintering process to make positive electrode sheet;

[0046] b. The negative electrode configuration is that the mass ratio of zinc oxide and sodium hydroxide is 1:15, and it is first configured with pure water to form a solution with a sodium hydroxide concentration of 2mol / L, according to the mass ratio of zinc oxide, sodium hydroxide and lignin powder 1:20, add lignin, after high-speed dispersion, then add 25% chitosan of lignin mass, stir in vacuum to form a solution; then add 2300% lignin mass of AB 2 Hydrogen storage alloy, after stirring evenly, vacuum defoaming into slurry. A separator made of nickel plate and nickel foam with lugs were inserted into the fixing tank, then the slurry was poured into the fixing tank, and then dried in a vacuum freeze dryer at -10°C for 36 hours. Finally, in a vac...

Embodiment 3

[0050] The preparation method of capacitive nickel-metal hydride power battery comprises the steps:

[0051] a. Prepare positive electrode battery slurry, and make positive electrode sheet by conventional semi-dry process;

[0052] b. The negative electrode configuration is that the mass ratio of zinc oxide and sodium hydroxide is 1:12, and it is first configured with pure water to form a solution with a concentration of sodium hydroxide of 2mol / L, according to the mass ratio of zinc oxide, sodium hydroxide and lignin powder 1:18, add lignin, after high-speed dispersion, then add 22% polyvinyl alcohol of lignin mass, stir in vacuum to form a solution; then add 2000% lignin mass of AB 3.5 Hydrogen storage alloy, after stirring evenly, vacuum defoaming into slurry. Insert a stainless steel separator and a nickel-plated steel strip with lugs into the fixing tank, then pour the slurry into the fixing tank, and then dry it in a vacuum freeze dryer at -30°C for 28 hours. Finally, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com