Curing agent for carboxyl resin, preparation method and composition applying curing agent

A technology of carboxyl resin and curing agent, which is applied in the field of curing agent for carboxyl resin and its preparation, can solve the problems such as the inability to apply a light curing system, and achieves the effects of avoiding mass generation, avoiding by-products, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

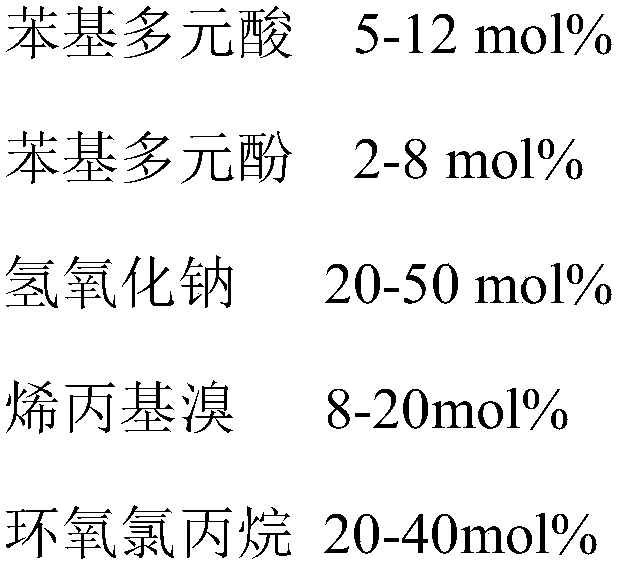

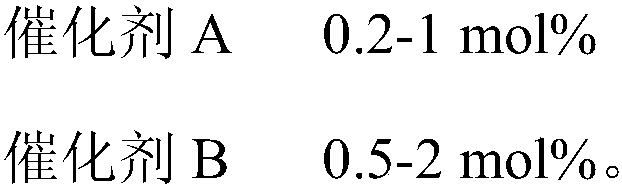

[0047] A curing agent for carboxyl resin, which is made by reacting phenyl polyacid, phenyl polyphenol, sodium hydroxide, allyl bromide, and epichlorohydrin as main raw materials. The raw materials include: trimellitic acid 7mol, phloroglucinol 4mol, sodium hydroxide 40mol, allyl bromide 12mol, epichlorohydrin 35mol, methimazole 0.5mol, 1-(4-fluorophenyl) biguanide 1.5mol;

[0048] Prepared by a method comprising the following steps:

[0049] (1) Preparation of sodium salt: Add pyromellitic acid and catechol to the reaction kettle, add aqueous sodium hydroxide solution, and raise the temperature to 70°C under stirring conditions for full neutralization reaction. After 3 hours, the reaction The final material was spray-dried to obtain a white powdery solid (water content less than 0.3%);

[0050] (2) Preparation of intermediate: Add the white solid, catalyst A and solvent n-hexane obtained in step (1) into the reactor, and heat it to reflux under stirring; slowly add allyl bromi...

Embodiment 2

[0053] A curing agent for carboxyl resin, which is made by reacting phenyl polyacid, phenyl polyphenol, sodium hydroxide, allyl bromide, and epichlorohydrin as main raw materials. The raw materials include the following: pyromellitic acid 2 mol of dianhydride, 8 mol of phthalic acid, 7 mol of resorcinol, 35 mol of sodium hydroxide, 14 mol of allyl bromide, 31.8 mol of epichlorohydrin, 0.3 mol of benzimidazole, 1.9 mol of metformin hydrochloride;

[0054] Prepared by a method comprising the following steps:

[0055] (1) Preparation of sodium salt: Add pyromellitic dianhydride, trimellitic acid, and resorcinol into the reaction kettle, add aqueous sodium hydroxide solution, and heat it up to 60°C under stirring conditions for full neutralization After 2 hours of reaction, the reacted material was spray-dried to obtain a white powdery solid (water content less than 0.3%);

[0056] (2) Preparation of intermediate: Add the white solid, catalyst A and solvent n-hexane obtained in s...

Embodiment 3

[0059] A curing agent for carboxyl resin, which is made by reacting phenyl polyacid, phenyl polyphenol, sodium hydroxide, allyl bromide, and epichlorohydrin as main raw materials. The raw materials include trimesic acid 5mol, isophthalic acid 6mol, catechol 6mol, sodium hydroxide 24.2mol, allyl bromide 18mol, epichlorohydrin 39mol, methimazole 0.7mol, metformin hydrochloride 1.1mol;

[0060] Prepared by a method comprising the following steps:

[0061] (1) Preparation of sodium salt: Add trimesic acid, isophthalic acid, and hydroquinone to the reaction kettle, add aqueous sodium hydroxide solution, and heat it up to 80°C under stirring conditions to fully neutralize the reaction. After 1 h, the reacted material was spray-dried to obtain a white powdery solid (water content less than 0.3%);

[0062] (2) Preparation of intermediate: Add the white solid, catalyst A and solvent n-hexane obtained in step (1) into the reactor, and heat it to reflux under stirring; slowly add allyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com