Biomass granular fuel with high adhesion, and preparation method of biomass granular fuel

A technology of biomass fuel and biomass particles, which is applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of high cost of additives and difficult realization of each component of additives, and achieve low inorganic component content, fuel processing performance and equipment power. Loss improvement, high wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

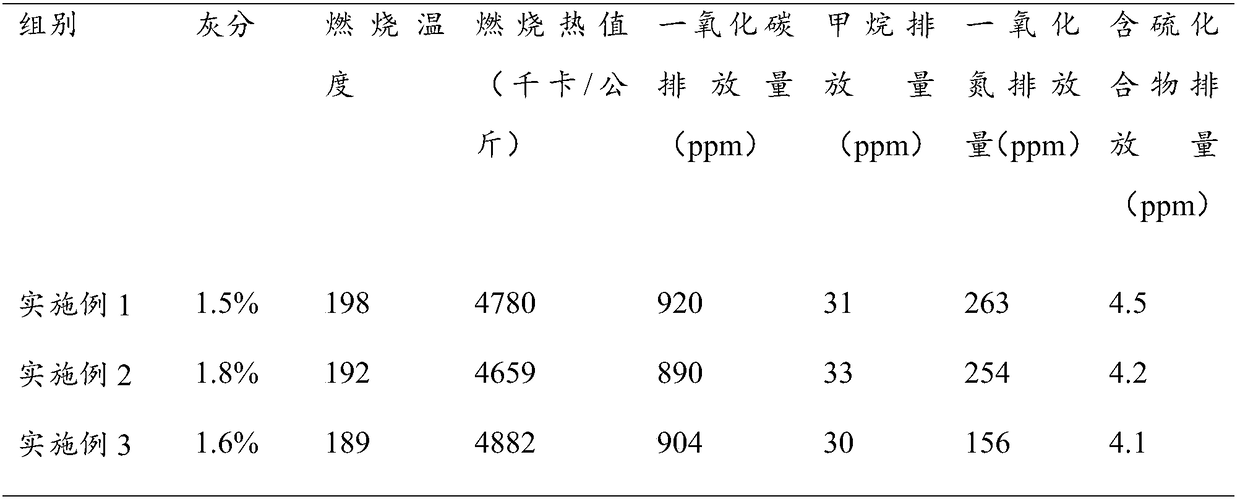

Embodiment 1

[0017] The preparation of the high biomass particle fuel of embodiment 1 caking degree

[0018] A biomass fuel particle with high cohesiveness, which is composed of the following raw materials in parts by weight: 60 parts of corn straw, 55 parts of rice straw, 15 parts of waste paper pulp, 5 parts of magnesium oxide, 4 parts of sodium hydroxide, sodium chloride 2 parts, potassium chlorate 3 parts, manganese dioxide 4 parts, lime milk or carbide slag 5 parts.

[0019] The preparation method of the biomass fuel particles with high cohesiveness comprises the following steps:

[0020] Step 1. After drying, pulverizing, mixing, and pressing the above-mentioned portions of corn stalks and rice stalks respectively, continue the pyrolysis and gasification reaction, and after cooling, crush them into powder again for later use. The drying temperature is 90-120°C ;

[0021] Step 2, grinding waste paper pulp, magnesium oxide, sodium chloride, potassium chlorate, manganese dioxide, milk...

Embodiment 2

[0023] Embodiment 2: the preparation of the high cohesiveness biomass particle fuel

[0024] A biomass fuel particle with high cohesiveness, which is composed of the following raw materials in parts by weight: 65 parts of corn straw, 60 parts of rice straw, 20 parts of waste paper pulp, 7 parts of magnesium oxide, 6 parts of sodium hydroxide, sodium chloride 4 parts, potassium chlorate 5 parts, manganese dioxide 6 parts, lime milk or carbide slag 10 parts.

[0025] The preparation method of the biomass fuel particles with high cohesiveness comprises the following steps:

[0026] Step 1. After drying, pulverizing, mixing, and pressing the above-mentioned portions of corn stalks and rice stalks respectively, continue the pyrolysis and gasification reaction, and after cooling, crush them into powder again for later use. The drying temperature is 90-120°C ;

[0027] Step 2, grinding waste paper pulp, magnesium oxide, sodium chloride, potassium chlorate, manganese dioxide, milk o...

Embodiment 3

[0029] Embodiment 3: the preparation of the high cohesive biomass particle fuel

[0030] The high cohesiveness of the biomass pellet fuel of the present embodiment, its raw material composition and preparation method are as follows:

[0031] A biomass fuel particle with high cohesiveness, which is composed of the following raw materials in parts by weight: 62 parts of corn straw, 58 parts of rice straw, 18 parts of waste paper pulp, 6 parts of magnesium oxide, 5 parts of sodium hydroxide, sodium chloride 3 parts, potassium chlorate 4 parts, manganese dioxide 5 parts, lime milk or carbide slag 8 parts.

[0032] The preparation method of the biomass fuel particles with high cohesiveness comprises the following steps:

[0033] Step 1. After drying, pulverizing, mixing and pressing the above-mentioned parts of corn stalks, rice stalks and waste paper pulp respectively, continue the pyrolysis and gasification reaction, and after cooling, crush them into powder again for later use....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com