Method for preparing organic active concrete by using sludge improvement and modification

A technology for activated concrete and silt, applied in chemical instruments and methods, sludge treatment, climate sustainability, etc., can solve the problems of complex silt components, harm, damage to plant nutrient balance, etc. The effect of agricultural soil quality and improvement of recycling value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

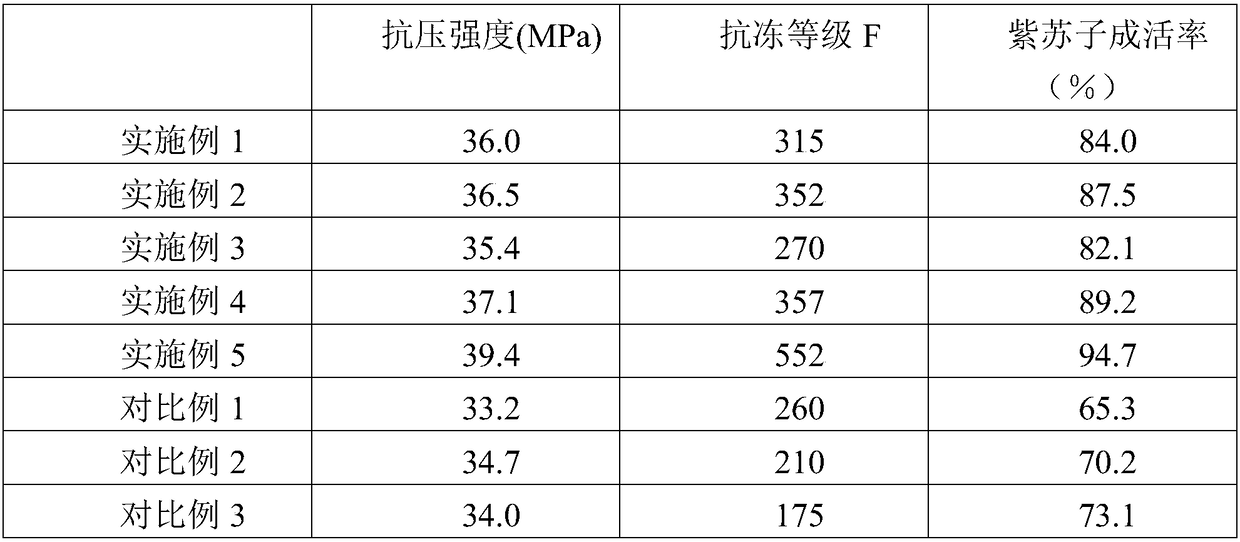

Examples

Embodiment 1

[0062] A method for preparing organic active concrete by improving and modifying silt, comprising the following steps, and the parts are parts by weight:

[0063] (1) Mix 100 parts of sludge and 5 parts of biodegradation solution evenly, then heat at 30°C for 6 hours for deodorization treatment, then add 15 parts of organic synthetic curing agent and mix evenly, heat at 30°C for 12 hours to obtain improved sludge;

[0064] (2) Mix the improved silt of step (1) with 140 parts of Portland cement, 50 parts of river sand, 50 parts of fly ash, and 800 parts of gravel and stir for 60 seconds at a speed of 50 rpm, then add 110 parts of water, Stir at a speed of 50 rpm for 60 seconds to obtain organic active concrete.

[0065] The organic synthetic curing agent includes the following components in mass percentage: 12% sodium silicate, 16% water-absorbing resin, 7% talcum powder, 10% river sand, 5% polyvinyl alcohol, and the balance is quicklime. Mix the raw materials evenly to obtain...

Embodiment 2

[0069] A method for preparing organic active concrete by improving and modifying silt, comprising the following steps, and the parts are parts by weight:

[0070] (1) Mix 100 parts of sludge and 5 parts of biodegradation solution evenly, then heat at 30°C for 6 hours for deodorization treatment, then add 15 parts of organic synthetic curing agent and mix evenly, heat at 30°C for 12 hours to obtain improved sludge;

[0071] (2) Mix the improved silt of step (1) with 140 parts of Portland cement, 50 parts of river sand, 50 parts of fly ash, and 800 parts of gravel and stir for 60 seconds at a speed of 50 rpm, then add 110 parts of water, Stir at a speed of 50 rpm for 60 seconds to obtain organic active concrete.

[0072] The organic synthetic curing agent includes the following components in mass percentage: 12% sodium silicate, 16% water-absorbing resin, 7% talcum powder, 10% river sand, 5% polyvinyl alcohol, and the balance is quicklime. Mix the raw materials evenly to obtain...

Embodiment 3

[0076] A method for preparing organic active concrete by improving and modifying silt, comprising the following steps, and the parts are parts by weight:

[0077] (1) Mix 100 parts of sludge and 5 parts of biodegradation solution evenly, then heat at 30°C for 6 hours for deodorization treatment, then add 15 parts of organic synthetic curing agent and mix evenly, heat at 30°C for 12 hours to obtain improved sludge;

[0078] (2) Mix the improved silt of step (1) with 140 parts of Portland cement, 50 parts of river sand, 50 parts of fly ash, and 800 parts of gravel and stir for 60 seconds at a speed of 50 rpm, then add 110 parts of water, Stir at a speed of 50 rpm for 60 seconds to obtain organic active concrete.

[0079] The organic synthetic curing agent includes the following components in mass percentage: 12% sodium silicate, 16% water-absorbing resin, 7% talcum powder, 10% river sand, 5% polyvinyl alcohol, and the balance is quicklime. Mix the raw materials evenly to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com