Hybrid laser welding method and device for transparent brittle materials

A brittle material, laser welding technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of surface ablation, slow processing speed, cracking, etc., and achieve the effect of strong applicability, firm and reliable welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

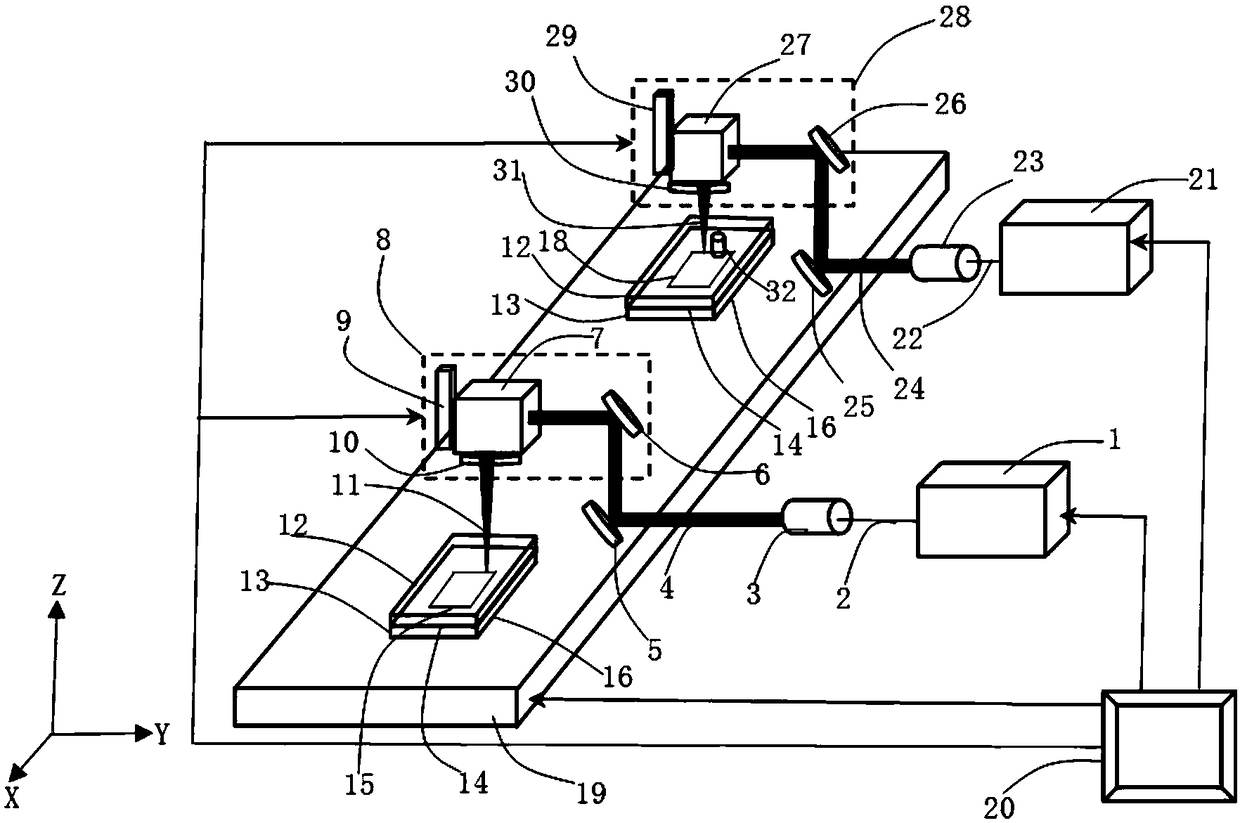

Image

Examples

Embodiment 1

[0044] Using a Nd:YAG picosecond laser with an output wavelength of 1064nm, a pulse width of 10ps, a maximum output power of 90W, and a pulse repetition frequency of 1MHz, and a fiber continuous laser with an output wavelength of 1064nm and a maximum output power of 100W, two natural stacked The ordinary soda-lime glass with a size of 50×25mm and a thickness of 1mm is placed, and the gap between two pieces of glass stacked is 15μm. The focus of the picosecond laser and the continuous laser are both in the gap between the two natural stacked glasses. S speed scans the initial weld of a rectangular seal with a length of 20mm and a width of 10mm; then move the welding material under the continuous laser scanning unit, start the continuous laser, output a 40W power beam, and pass through the scanning galvanometer and the f-θ flat-field scanning lens. Seal the initial weld along a rectangle with a length of 20mm and a width of 10mm, and perform scanning welding at a speed of 10mm / s...

Embodiment 2

[0046] Using a Nd:YAG picosecond laser with an output wavelength of 1064nm, a pulse width of 10ps, a maximum output power of 90W, and a pulse repetition frequency of 1MHz, and a fiber continuous laser with an output wavelength of 1064nm and a maximum output power of 100W, two stacked Dissimilar glass with a size of 60×40mm and a thickness of 2mm. The upper layer is quartz glass and the lower layer is soda-lime glass. The gap between the two glasses is 20μm. The composite laser welding method for brittle materials is adopted. The focus of the picosecond laser and the continuous laser are both in the gap between two pieces of natural stacked glass. -θ flat-field scanning lens, scanning the rectangular sealing initial welding seam with a length of 40mm and a width of 30mm at a speed of 3000mm / s to form a 40×30mm rectangular white translucent initial welding seam; after that, the welding material is moved to the continuous laser scanning unit Below, start the continuous laser to o...

Embodiment 3

[0048] Use a Nd:YAG picosecond laser with an output wavelength of 1064nm, a pulse width of 10ps, a maximum output power of 90W, and a pulse repetition frequency of 1MHz, and a fiber continuous laser with an output wavelength of 1064nm and a maximum output power of 100W to weld two stacks. Quartz glass with a size of 50×50mm and a thickness of 1.5mm is placed, and the gap between two pieces of glass stacked is 25μm. Using the composite laser welding method for brittle materials, the focus of the picosecond laser and the continuous laser are both in the gap between the two natural stacked glasses. -θ flat-field scanning lens, scanning the square sealing initial welding seam with a length of 40mm and a width of 40mm at a speed of 4000mm / s to form a 40×40mm square white translucent initial welding seam; after that, the welding material is moved to the continuous laser scanning system Below, start the continuous laser to output a continuous beam of 80W power, pass through the scann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com