Preparation method of a highly transparent photoluminescent zinc oxide-polyethylene composite coating

A technology of photoluminescence and composite coating, which is applied in the direction of coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems affecting the physical and chemical properties of the composite coating, achieve strong ultraviolet light emission ability, Weak blue light emission characteristics, high transmittance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

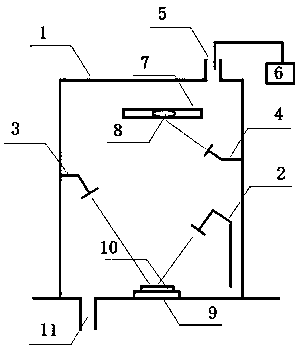

[0034] Such as figure 1 As shown, the present invention adopts a pulsed laser-assisted low-energy electron beam evaporation device, including a vacuum chamber 1, an electron beam evaporator 2, a pulsed laser auxiliary device 3, a quartz crystal thickness gauge 8 and a sample holder 7; a target 10 and The crucible 9 is fixed on the bottom of the vacuum chamber 1, and the substrate is fixed above the crucible 9 through the sample holder 7, so that the substrate is in the atmosphere formed by gas phase particles, and the coating passes through the gas flow meter 6 through the gas inlet 5 before the coating is deposited. The argon gas is introduced, and the substrate is cleaned by sputtering through the ion source 4. The electron beam evaporator 2 is fixed on the upper right of the target 10 so that the electron beam can be irradiated on the target, and the pulsed laser auxiliary device 3 is fixed on the target through the bracket The upper left of the material, so that the laser ...

Embodiment 2

[0043] This embodiment provides a method for preparing a highly transparent photoluminescent zinc oxide-polyethylene composite coating using the device described in Embodiment 1, comprising the following steps:

[0044] (1) Substrate pretreatment: Polished single crystal silicon and quartz glass are used as substrates. Before deposition, ultrasonically clean in acetone, ethanol and deionized water for 20 minutes to remove other surface pollutants, and dry with cold air for later use;

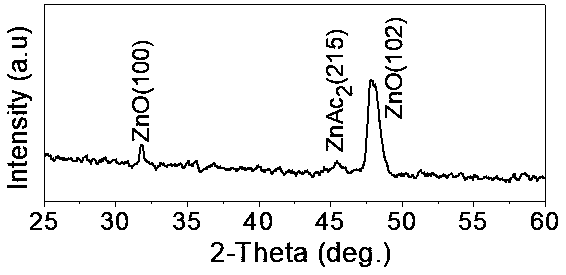

[0045] (2) Evaporation target prefabrication: using anhydrous zinc acetate and low-density polyethylene powder as raw materials, mechanically mixing the two at a mass ratio of 1:1, and pressing them in a mold as the evaporation target 10;

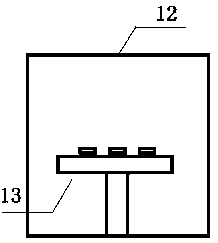

[0046] (3) Fix the pretreated substrate on the sample holder 7 in the self-made pulse laser-assisted low-energy electron beam evaporation device, place the prefabricated target 10 in the evaporation source crucible 9 in the vacuum chamber, and adjust the targ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com