High temperature resisting thixotropic cement slurry system and preparation method thereof

A technology for high temperature resistance, cementing slurry, applied in chemical instruments and methods, drilling composition, etc., can solve the problem of small improvement in thixotropy of cement slurry system, decline in sealing quality, limited thixotropic performance of cement slurry system, etc. problems, to meet the cementing construction strength requirements, save operation time and cost, and achieve good settlement stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

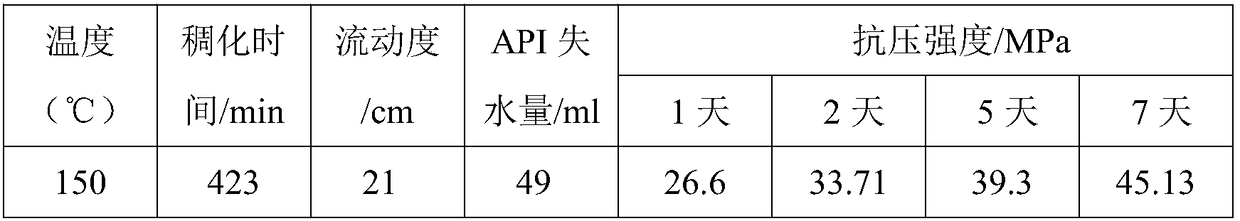

Embodiment 1

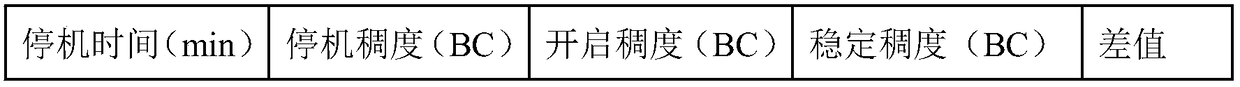

[0042] Consistency value-added experiment test temperature: 90°C

[0043]High temperature thixotropy and anti-gas channeling cement system cement slurry formula: cement 600g, micro silicon 60g, retarder (ethylene hydroxydiphosphonic acid and its salt) 12g, fluid loss reducer (vinyl composite polymer) 15g, Dispersant (sulfonated aldehyde and ketone polycondensate) 12g, defoamer (modified polyether ester) 3g, sodium hydroxide 1g, potassium chloride 6g, konjac gum 0.6g, xanthan gum 6g, silica sand (80 mesh 90g, 180 mesh 210g), water 318g.

[0044] Preparation method of high temperature thixotropy and anti-gas channeling cement system:

[0045] (1) Take by weighing xanthan gum, konjac gum, sodium hydroxide, tap water of above-mentioned weight, stir, be configured into solution, add the water loss reducer (vinyl composite polymer) of formulation amount in above-mentioned solution, stand still under room temperature After 3 hours, add retarder (ethylene hydroxydiphosphonic acid an...

Embodiment 2

[0047] Consistency value-added experiment test temperature: 90°C

[0048] High temperature thixotropy and anti-gas channeling cement system cement slurry formula: cement 600g, micro silicon 48g, retarder (ethylene hydroxydiphosphonic acid and its salt) 12g, fluid loss reducer (vinyl composite polymer) 12g, Dispersant (sulfonated aldehyde and ketone condensation polymer) 24g, defoamer (modified polyether ester) 6g, sodium hydroxide 0.6g, potassium chloride 7.5g, konjac gum 0.75g, xanthan gum 7.5g, silica sand (80 Mesh 90g, 180 mesh 210g), water 348g.

[0049] The preparation method of the high-temperature thixotropy and anti-gas channeling cement system: it is prepared according to the preparation method of the high temperature-resistant thixotropy and anti-gas channeling cement system described in Example 1.

Embodiment 3

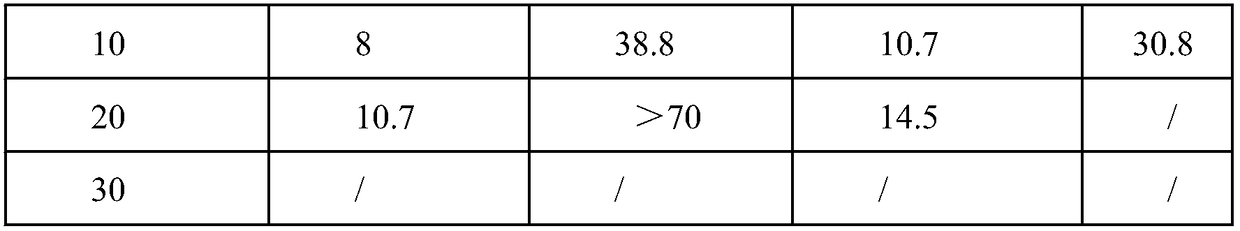

[0051] Consistency value-added experiment test temperature: 110°C

[0052] Cement slurry formula: cement 600g, micro silicon 78g, retarder (ethylene hydroxydiphosphonic acid and its salt) 15g, fluid loss reducer (vinyl composite polymer) 18g, dispersant (sulfonated aldehyde and ketone condensation polymer) ) 24g, defoamer (modified polyether ester) 3g, sodium hydroxide 1g, potassium chloride 6g, hydrogen konjac gum 0.6g, xanthan gum 6g, silica sand (80 mesh 90g, 180 mesh 210g), water 348g.

[0053] Preparation method: Prepare according to the preparation method of the high temperature thixotropy and anti-gas channeling cement system described in Example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com