Ferment liquid-state fertilizer and production method thereof

A liquid fertilizer and enzyme technology, applied in liquid fertilizers, organic fertilizers, inorganic fertilizers, etc., can solve the problems of small market share of new microbial organic fertilizers, increase the amount of pesticides used to eliminate pests and diseases, and weaken the ability of crops to resist pests and diseases. Risk of species invasion, elimination of soil-borne diseases, increase in fertility and the effect of disease-resistant beneficial bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

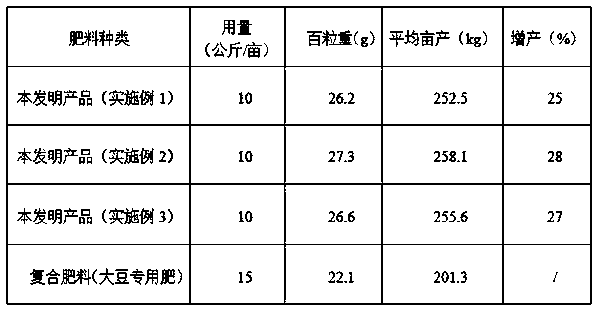

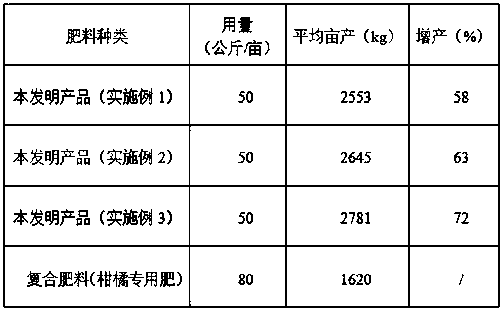

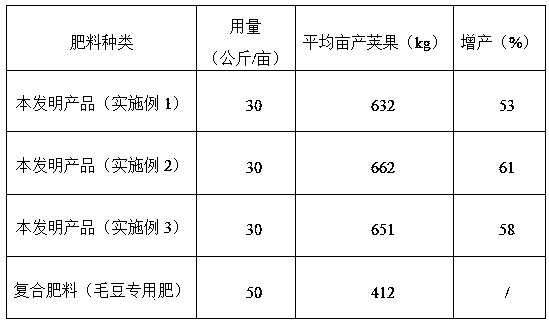

Embodiment 1

[0033] A kind of enzyme liquid fertilizer, it is produced by weight parts by following composition:

[0034] 60 parts of apple peel, 60 parts of banana peel, 60 parts of watermelon peel, 50 parts of citrus peel residue, 50 parts of guava leaf, 80 parts of plant ash, 25 parts of sucrose, 10 parts of medium elements, 3 parts of trace elements, and 8 parts of polyvinyl alcohol 8 parts of shell powder, 6 parts of pectin compound enzyme, 6 parts of enzyme bacteria, 3 parts of EM bacteria group.

[0035] The trace element is a mixture of ferrous sulfate, copper sulfate, zinc sulfate, manganese sulfate, borax and ammonium molybdate; the weight ratio is 1:0.5:0.5:0.8:0.2:0.1.

[0036] The medium element is a mixture of calcium magnesium phosphate fertilizer, peat soil and potassium sulfate; the weight ratio is 1:1:0.5.

[0037] The pectin compound enzyme adopts Aspergillus microorganism to carry out solid enzyme fermentation. The weight ratio of fermentation medium raw materials is: ...

Embodiment 2

[0044] A kind of enzyme liquid fertilizer, it is produced by weight parts by following composition:

[0045] 90 parts of apple peel, 90 parts of banana peel, 90 parts of watermelon peel, 75 parts of citrus peel residue, 75 parts of guava leaf, 100 parts of plant ash, 30 parts of sucrose, 12 parts of medium elements, 4 parts of trace elements, 9 parts of polyvinyl alcohol 9 parts of shell powder, 7 parts of pectin compound enzyme, 7 parts of enzyme bacteria, and 4 parts of EM flora.

[0046] The trace element is a mixture of ferrous sulfate, copper sulfate, zinc sulfate, manganese sulfate, borax and ammonium molybdate; the weight ratio is 1:0.5:0.5:0.8:0.2:0.1.

[0047] The medium element is a mixture of calcium magnesium phosphate fertilizer, peat soil and potassium sulfate; the weight ratio is 1:1:0.5.

[0048] The pectin compound enzyme adopts Aspergillus microorganism to carry out solid enzyme fermentation. The weight ratio of fermentation medium raw materials is: beer tan...

Embodiment 3

[0055] A kind of enzyme liquid fertilizer, it is produced by weight parts by following composition:

[0056] 120 parts of apple peel, 120 parts of banana peel, 120 parts of watermelon peel, 100 parts of citrus peel residue, 100 parts of guava leaf, 120 parts of plant ash, 35 parts of sucrose, 15 parts of medium elements, 5 parts of trace elements, 10 parts of polyvinyl alcohol 10 parts of shell powder, 8 parts of pectin complex enzyme, 8 parts of enzyme bacteria, 5 parts of EM bacteria group.

[0057] The trace element is a mixture of ferrous sulfate, copper sulfate, zinc sulfate, manganese sulfate, borax and ammonium molybdate; the weight ratio is 1:0.5:0.5:0.8:0.2:0.1.

[0058] The medium element is a mixture of calcium magnesium phosphate fertilizer, peat soil and potassium sulfate; the weight ratio is 1:1:0.5.

[0059] The pectin compound enzyme adopts Aspergillus microorganism to carry out solid enzyme fermentation. The weight ratio of fermentation medium raw materials i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com