Electrolyzed seawater hydrogen production catalyst based on MXene and transition metal carbide composite nanostructure and synthesis method thereof

A composite nanostructure, transition metal technology, applied in the fields of nanomaterials, energy and catalysis, can solve the problems of transition metal carbide nanocatalysts, performance degradation, poor stability, etc., to achieve excellent catalytic activity and stability, process green environmental protection , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 is based on the preparation method of the composite nanocatalyst of MXene and cobalt molybdenum carbide

[0031] 1) Prepare 30mL tris-hydrochloric acid buffer solution, add 100mg ammonium molybdate tetrahydrate, 20mg cobalt chloride hexahydrate, 20mg dopamine and 5mL MXene dispersion (5.0mg mL -1 ), stirring reaction 24h. After the reaction, it was repeatedly washed with deionized water until neutral, centrifuged, and freeze-dried to obtain a black powder.

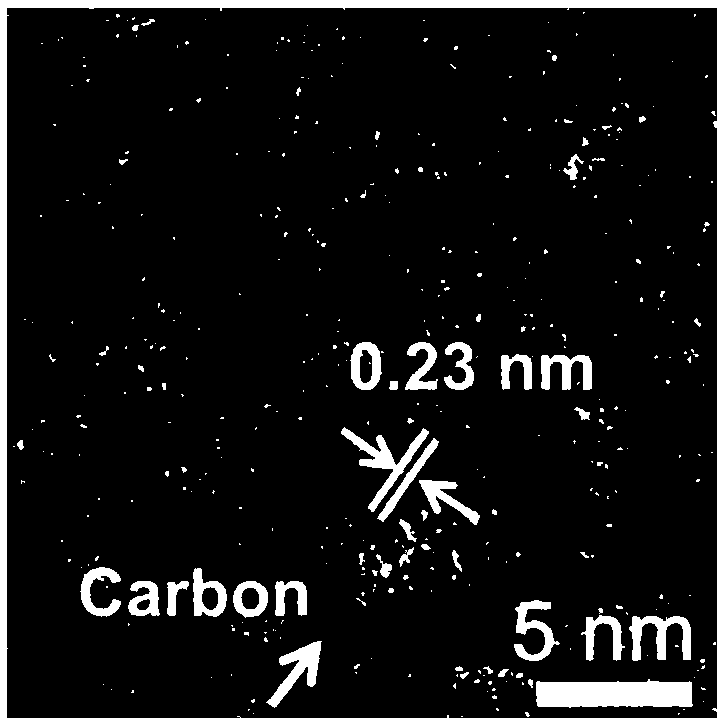

[0032] 2) Under the protection of Ar gas, place the product prepared in step 2) in a high-temperature furnace for calcination to obtain a nanocatalyst based on MXene and cobalt-molybdenum carbide. The calcination temperature is 750oC, and the calcination time is 3h. The obtained product has an average size of about 100-500nm, two-dimensional flake nanoparticles loaded with cobalt-molybdenum carbide nanoparticles, the size of the cobalt-molybdenum carbide nanoparticles is about several nanometers, and t...

Embodiment 2

[0033] Embodiment 2 is based on the preparation method of the composite nano-catalyst of MXene and nickel-molybdenum carbide

[0034] 1) Prepare 30mL tris-hydrochloric acid buffer solution, add 100mg ammonium molybdate tetrahydrate, 20mg nickel chloride hexahydrate, 20mg dopamine and 5mL MXene dispersion (5.0mg mL -1 ), stirring reaction 24h. After the reaction, it was repeatedly washed with deionized water until neutral, centrifuged, and freeze-dried to obtain a black powder.

[0035]2) Under the protection of Ar gas, place the product prepared in step 2) in a high-temperature furnace for calcination to obtain a nanocatalyst based on MXene and cobalt-molybdenum carbide. The calcination temperature is 750oC, and the calcination time is 3h. The obtained product has an average size of about 100-500nm, two-dimensional flake nanoparticles loaded with nickel-molybdenum carbide nanoparticles, the size of the nickel-molybdenum carbide nanoparticles is about several nanometers, and t...

Embodiment 3

[0036] Embodiment 3 is based on the preparation method of the composite nanocatalyst of MXene and molybdenum carbide

[0037] 1) Prepare 30mL tris-hydrochloric acid buffer solution, add 100mg ammonium molybdate tetrahydrate, 20mg dopamine and 5mL MXene dispersion (5.0mg mL -1 ), stirring reaction 24h. After the reaction, it was repeatedly washed with deionized water until neutral, centrifuged, and freeze-dried to obtain a black powder.

[0038] 2) Under the protection of Ar gas, place the product prepared in step 2) in a high-temperature furnace for calcination to obtain a nanocatalyst based on MXene and cobalt-molybdenum carbide. The calcination temperature is 750oC, and the calcination time is 3h. The obtained product is about 100-500nm in average size, two-dimensional flake nanoparticles loaded with molybdenum carbide nanoparticles, the size of the molybdenum carbide nanoparticles is about several nanometers, and the surrounding is covered with a carbon layer with a thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com