A kind of preparation method of ion-filled graphite phase carbon nitride nanosheet

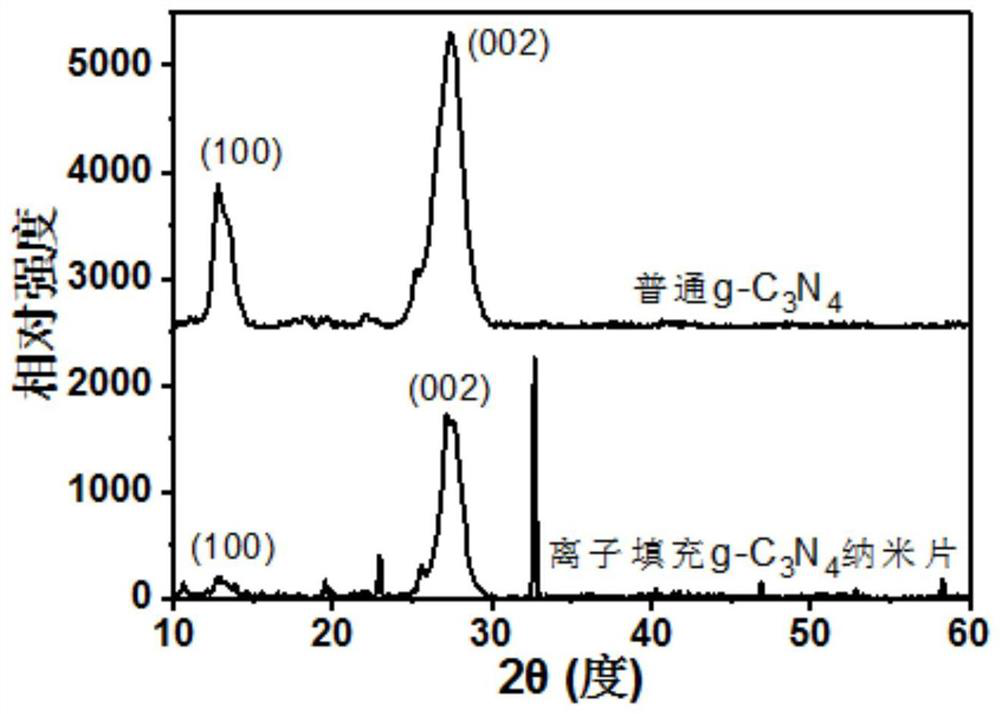

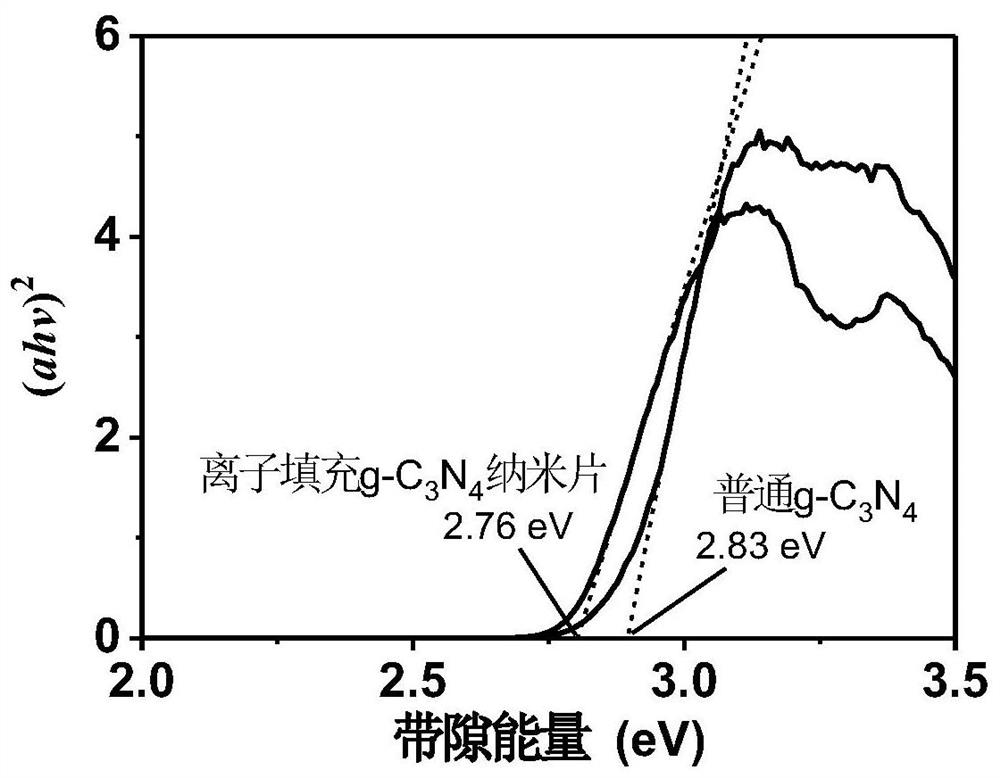

A graphite-phase carbon nitride and nanosheet technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of limited availability of photocatalytic reactions, increased energy band gap of nanosheets, limited application of nanosheets, etc. problem, to achieve the effect of eliminating the quantum size effect, reducing the energy band gap, and good photooxidative NO removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

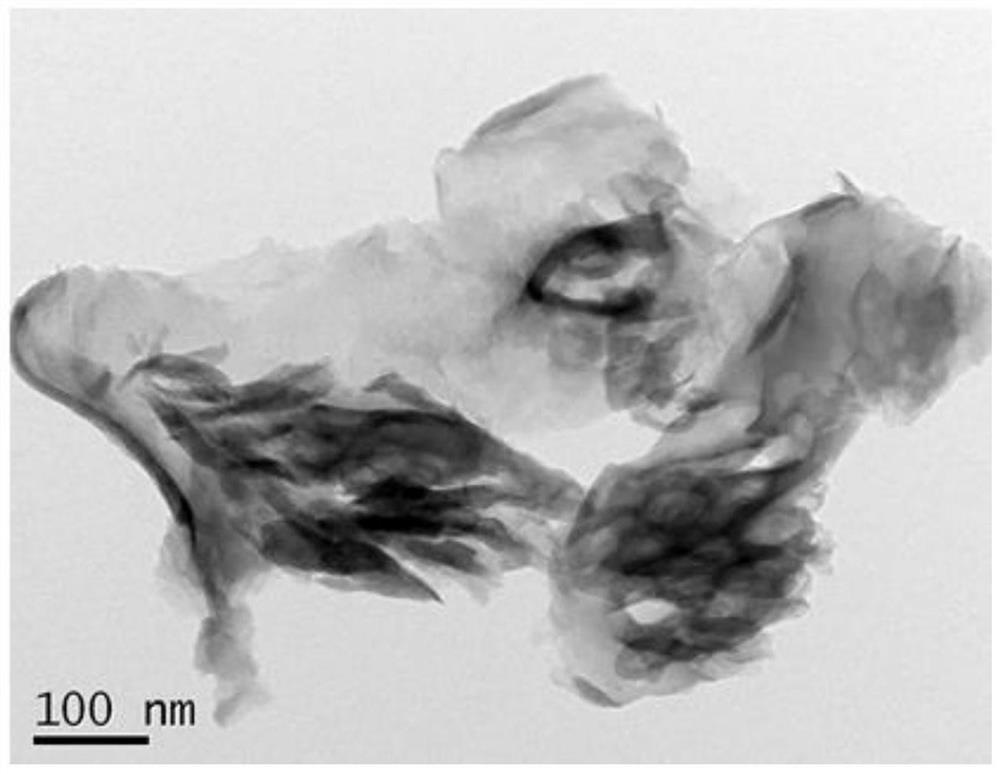

Image

Examples

Embodiment 1

[0029] A, with 2g analytical pure melamine (C 3 N 6 h 6 ) Add the solid powder into 100mL of deionized water heated in a water bath at 80°C, and at the same time, magnetically stir to accelerate the dissolution. After the solution is clarified, stop heating and stirring, and let it cool naturally;

[0030]b. When the clear solution obtained in step a is cooled until white crystals begin to precipitate, start stirring and slowly add 1 mL of concentrated hydrochloric acid (HCl) with a mass fraction of 37% to the solution dropwise to obtain a mixed solution;

[0031] c. Heating the mixed solution obtained in step b at 80°C for 30 minutes, and then drying it in a blast drying oven at 120°C for 24 hours to obtain white crystals;

[0032] d. Put the white crystal obtained in step c into a sealed 100mL calciner after careful grinding, continue to heat up to 520°C at a heating rate of 20°C / min, and calcine at a constant temperature of 520°C for 4 hours, and obtain a light yellow sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com