Ecological revetment based on in-situ solidification of dredged sludge and preparation method thereof

An ecological revetment and in-situ solidification technology, which is applied in ceramic products, coastline protection, infrastructure engineering, etc., to achieve the effects of stabilizing river slopes, regulating climate and beautifying the environment, and good water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The silt consolidating agent is an environmentally friendly underwater non-dispersible silt consolidating agent for ecological restoration. Its composition and mass parts are:

[0033] Aluminosilicate clinker 30%

[0034] Quicklime 15%

[0035] Desulfurization gypsum 10%

[0036] Metakaolin 20%

[0037] Bentonite 8%

[0038] Waterproofing agent 7%

[0039] Anti-dispersant 2%

[0040] Adsorbent 3%

[0041] Alkali Stimulator 5%

[0042]Among them, the waterproofing agent is a polymer emulsion compounded by 30% latex powder, 60% phenolic resin, and 10% polyvinyl alcohol; It is compounded with sodium; other components are all commercially available products.

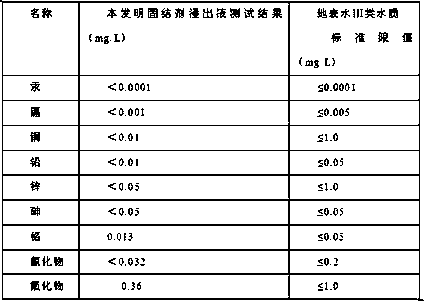

[0043] Table 1 Toxicity test results of consolidation agent leachate

[0044]

[0045] Table 1 is the performance test result of the sludge consolidation agent configured for the first time in the present invention, and it can be known from it that the toxicity test of the sample leachate of the environmen...

Embodiment 2

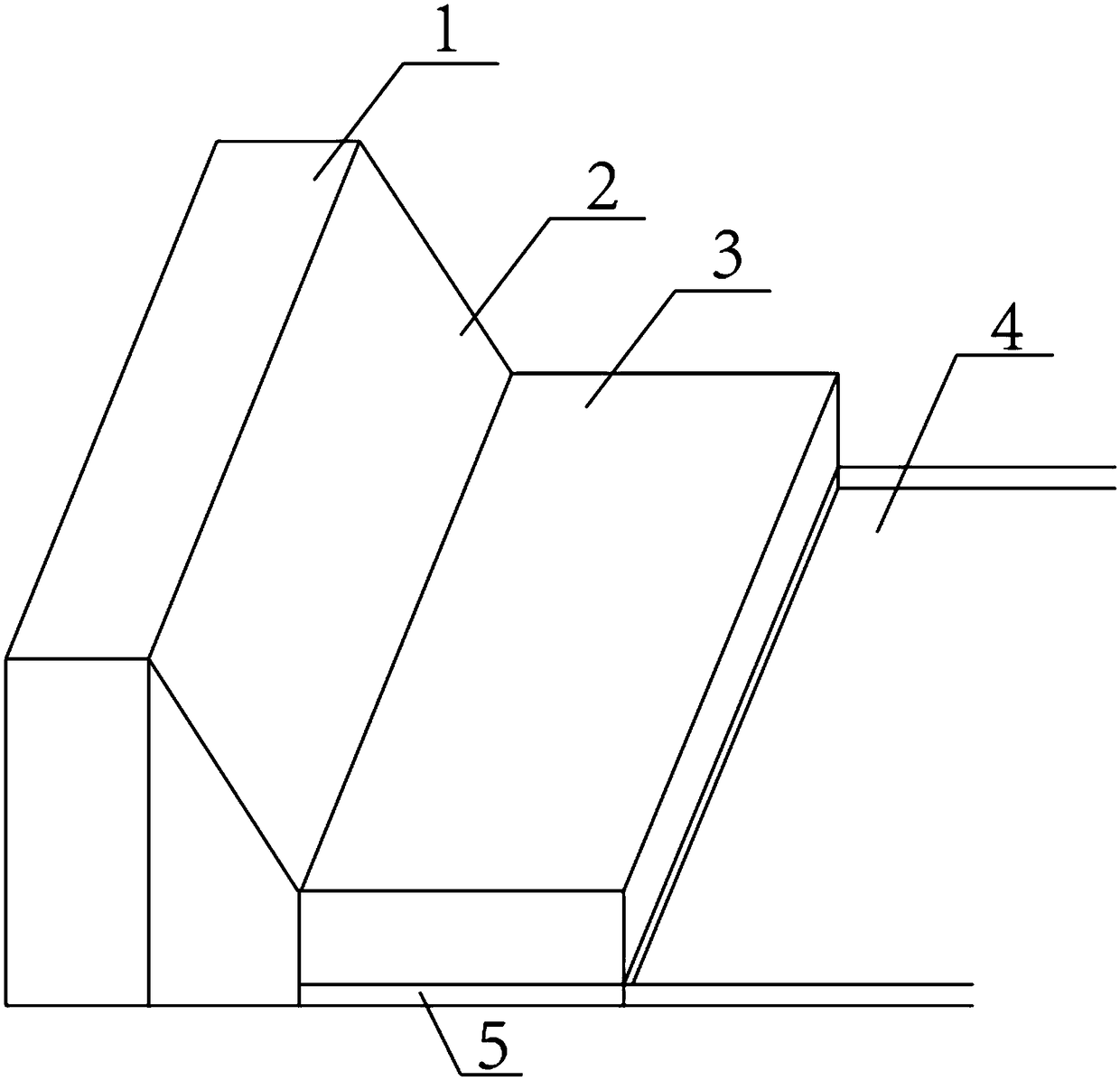

[0047] The preparation method of the ecological bank revetment solidified in situ by dredging mud comprises the following steps:

[0048] (1) By using the existing in-situ mixing equipment, the sediment at the bottom of the river slope is stirred and solidified in-situ and leveled, and naturally maintained in the water as the bottom foundation of the ecological revetment structural system;

[0049] (2) Support imitation wooden pile revetment formwork on the bottom of the water, and then use mechanical mud suction equipment to suck the dredged mud in the river into the vehicle-mounted mixing device, stir the dredged mud in the vehicle-mounted mixing device, and add consolidation agent, Microbial film-forming porous ash, foaming agent and rheological agent, fully stirred and prepared into fluid solidified silt slurry;

[0050] (3) Transport it to the supported imitation pile bank revetment formwork through the pumping device, after manual leveling, natural health preservation in...

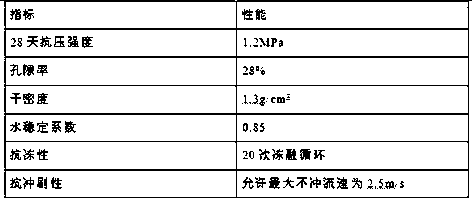

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com