Suspension stabilizer for high temperature cement slurry and high temperature resistant cement slurry prepared therefrom

A suspension stabilizer and cement slurry technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of affecting cement slurry ash time, cement slurry thickening, poor fluidity, etc., and improve high temperature suspension stability. properties, improve the strength of high temperature cement stone, improve the effect of mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

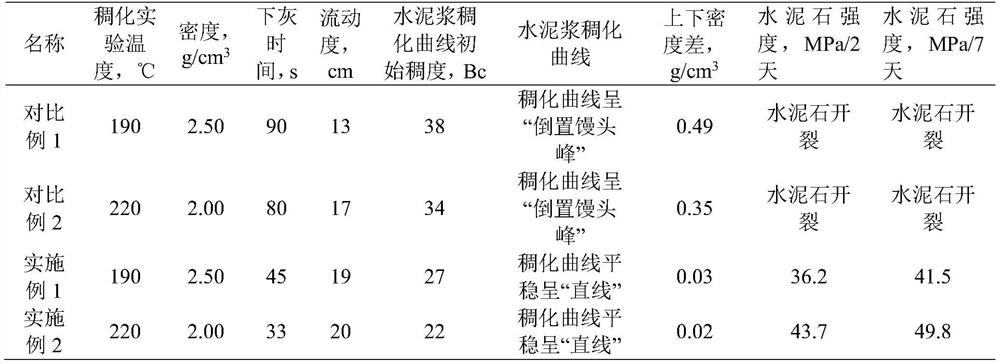

Embodiment 1

[0035] It consists of the following components in proportion by weight: 100 parts of Portland cement, 3 parts of suspension stabilizer for high-temperature cement slurry, 100 parts of iron ore powder, 50 parts of micromanganese ore powder, 35 parts of quartz sand, 79 parts of semi-saturated Salt water, 1 part of sulfonated melamine formaldehyde resin, 2 parts of AMPS polymer fluid loss reducer, 4 parts of AMPS polymer retarder, 0.3 part of tributyl phosphate. First dry mix the high-temperature cement slurry with suspension stabilizer, iron ore powder, micromanganese ore powder, quartz sand, aldehyde and ketone condensate dispersant, AMPS polymer fluid loss reducer and Portland cement; then mix AMPS polymer Retardant, tributyl phosphate and semi-saturated brine are wet mixed evenly; finally, under stirring conditions, add the dry mixture to the wet mixture, and stir evenly to obtain a high-temperature high-density cement slurry with a density of 2.50g / cm 3 .

[0036] Remarks: ...

Embodiment 2

[0038]It is composed of the following components in proportion by weight: 100 parts of Portland cement, 4 parts of suspension stabilizer for high temperature cement slurry, 25 parts of iron ore powder, 35 parts of quartz sand, 70 parts of fresh water, 0.8 part of sulfonated melamine formaldehyde Resin, 2 parts of AMPS polymer fluid loss reducer, 4 parts of AMPS polymer retarder, 0.3 part of tributyl phosphate. First dry mix the high-temperature cement slurry with suspension stabilizer, iron ore powder, micromanganese ore powder, quartz sand, aldehyde and ketone condensate dispersant, AMPS polymer fluid loss reducer and Portland cement; then mix AMPS polymer Retardant, tributyl phosphate and fresh water are mixed evenly; finally, under stirring conditions, add the dry mixture to the wet mixture, and stir evenly to obtain a high-temperature cement slurry with a density of 2.00g / cm 3 .

[0039] Remarks: The ratio of the suspension stabilizer for high-temperature cement slurry de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com