Insulating heat-conducting cable material and preparation method thereof

A technology of insulation and heat conduction, cable material, applied in the direction of organic insulators, heat exchange materials, chemical instruments and methods, etc., can solve the problems affecting the insulation performance of sheath materials, hidden safety hazards, etc., and achieve good matt effect and temperature resistance grade. High, improve the effect of flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

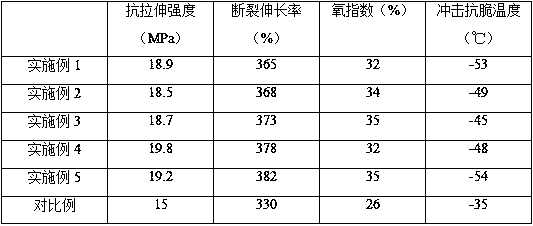

Examples

Embodiment 1

[0032] This embodiment relates to an insulating and heat-conducting cable material, including the following raw materials in parts by weight: 20 parts of high-density polyethylene, 10 parts of graphene-modified polypropylene, 15 parts of ethylene-vinyl acetate copolymer, 7 parts of gum arabic, montmorillonite 3 parts of soil, 4 parts of light calcium carbonate, 3 parts of glass fiber, 2 parts of polyethylene wax, 1 part of calcium stearate, 6 parts of flame retardant, 2 parts of plasticizer, 2 parts of reinforcing agent;

[0033] The preparation method of described graphene modified polypropylene is as follows:

[0034] a: Premixing polypropylene powder, stabilizer, acrylic resin and graphene nano-carbon material in a high-speed mixer to obtain a mixed powder, wherein the weight ratio of polypropylene powder, stabilizer, acrylic resin and graphene nano-carbon material is 100:8:2:1;

[0035] b: Melt and mix the mixed powder obtained in step a with a torque rheometer at 160° C....

Embodiment 2

[0047] This embodiment relates to an insulating and heat-conducting cable material, including the following raw materials in parts by weight: 30 parts of high-density polyethylene, 20 parts of graphene-modified polypropylene, 25 parts of ethylene-vinyl acetate copolymer, 11 parts of gum arabic, montmorillonite 6 parts of soil, 8 parts of light calcium carbonate, 7 parts of glass fiber, 4 parts of polyethylene wax, 3 parts of calcium stearate, 9 parts of flame retardant, 5 parts of plasticizer, 4 parts of reinforcing agent;

[0048] The preparation method of described graphene modified polypropylene is as follows:

[0049] a: Premixing polypropylene powder, stabilizer, acrylic resin and graphene nano-carbon material in a high-speed mixer to obtain a mixed powder, wherein the weight ratio of polypropylene powder, stabilizer, acrylic resin and graphene nano-carbon material is 100:8:2:1;

[0050] b: Melt and mix the mixed powder obtained in step a for 10 min at 180°C and 80 rpm w...

Embodiment 3

[0062] This embodiment relates to an insulating and heat-conducting cable material, including the following raw materials in parts by weight: 23 parts of high-density polyethylene, 11 parts of graphene-modified polypropylene, 18 parts of ethylene-vinyl acetate copolymer, 9 parts of gum arabic, montmorillonite 4 parts of soil, 5 parts of light calcium carbonate, 4 parts of glass fiber, 2.5 parts of polyethylene wax, 1.5 parts of calcium stearate, 7 parts of flame retardant, 3 parts of plasticizer, and 2.6 parts of reinforcing agent.

[0063] Wherein, the flame retardant is a mixture of magnesium hydroxide, aluminum hydroxide, antimony trioxide and silicon carbide, and the mass ratio of magnesium hydroxide, aluminum hydroxide, antimony trioxide and silicon carbide is 3:3 :2:1.

[0064] Wherein, the preparation method of described graphene modified polypropylene is as follows:

[0065] a: Premixing polypropylene powder, stabilizer, acrylic resin and graphene nano-carbon material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com