Iron-based quantum dot modified g-C3N4 visible light drive Fenton-like catalyst

A C3N4, g-c3n4 technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low efficiency of oxidative degradation of organic matter, secondary pollution recovery cost, small particle size, etc. To solve the problem of iron-containing sludge, reduce the loss of iron species, and achieve the effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

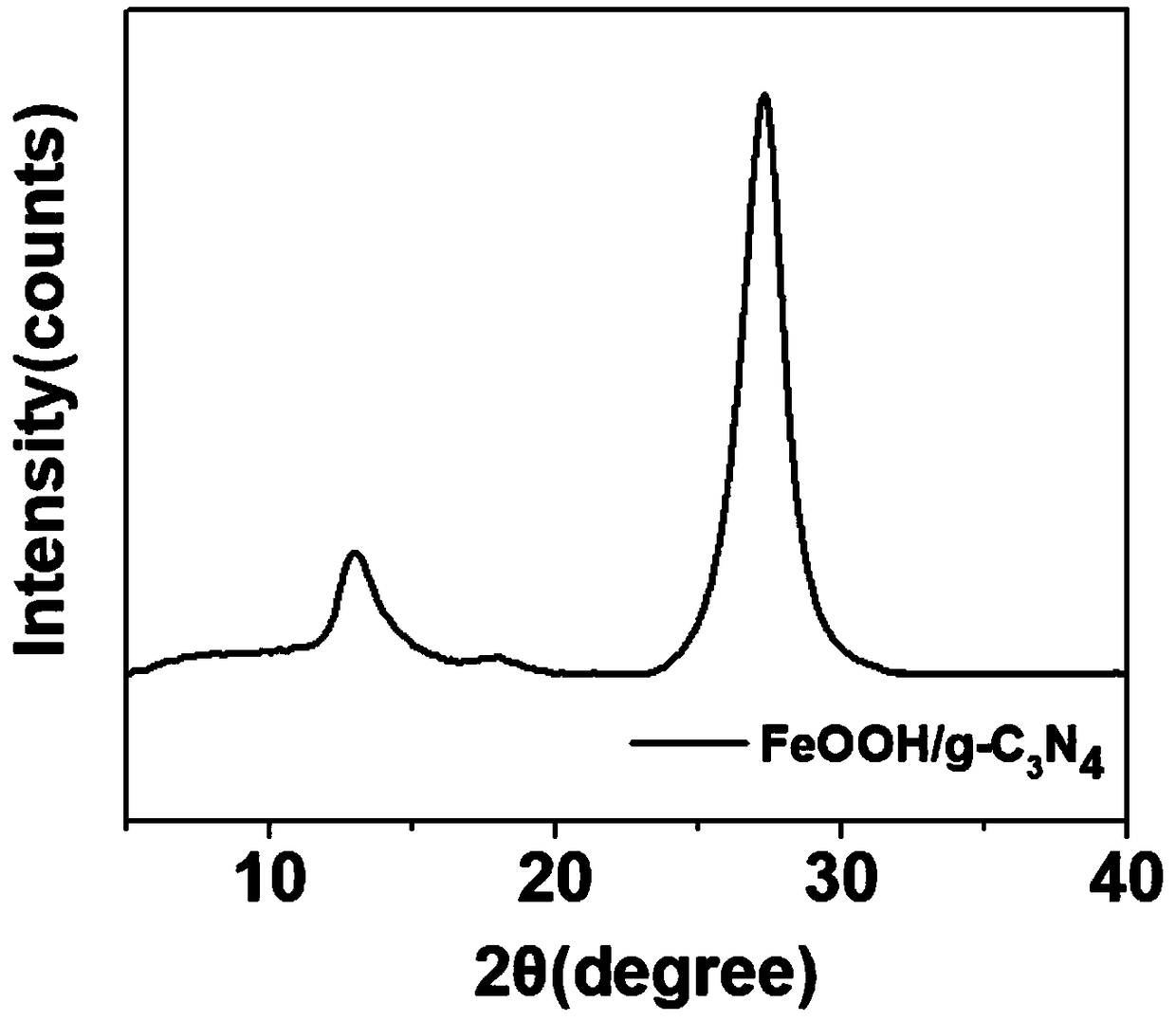

[0039] Prepare 5g / L ferric chloride hexahydrate-ethanol solution, draw 9.16ml of the solution into the volumetric flask, add the ethanol solution to make the volume to 50ml, stir magnetically to dissolve it completely; add the prepared g-C 3 N 4 3 g of solid was dispersed by ultrasonic for 10 min, 0.02 mg of ammonium bicarbonate powder was added, and magnetically stirred for 8 h in a fume hood. The solid sample was separated and collected, washed and filtered three times, and then vacuum-dried at 40°C to obtain a loaded 0.4% FeOOH / g-C 3 N 4 catalyst( figure 2 ),Depend on figure 2 It can be seen from the scanning electron microscope image that g-C 3 N 4 It is stacked in layers with a large surface area, and dispersed iron-based quantum dots appear on the layered support.

[0040] Change the amount of ferric chloride hexahydrate-ethanol solution and ammonium bicarbonate powder to 18.42ml, 0.02mg and 46.75ml, 0.20mg, respectively to obtain 0.9% FeOOH / g-C 3 N 4 Catalyst ...

Embodiment 2

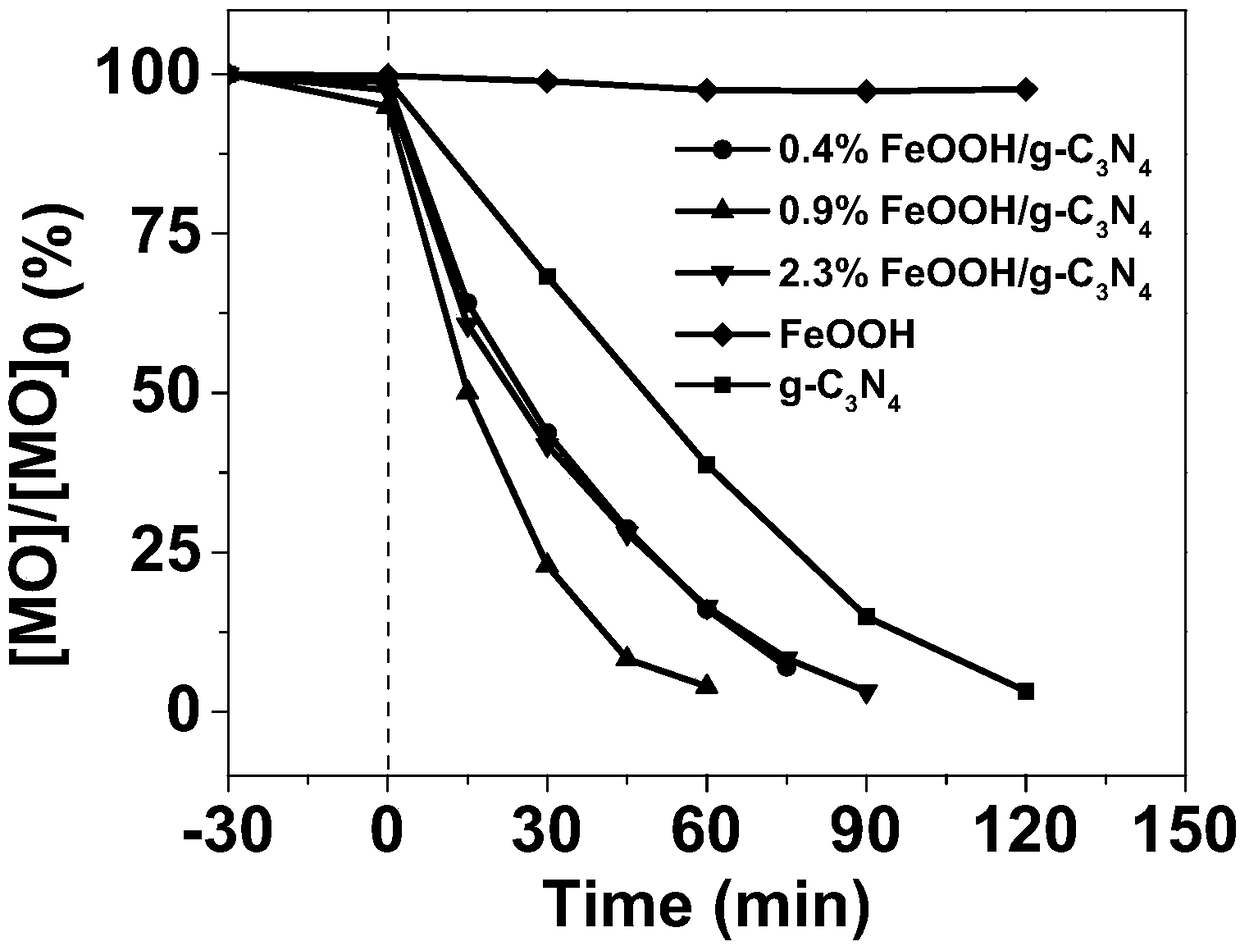

[0044] In 50ml of methyl orange solution (25mg / L), add 50mg of 0.4% FeOOH / g-C 3 N 4 , 0.9% FeOOH / g-C 3 N 4 , 2.3% FeOOH / g-C 3 N 4 Catalyst samples, magnetically stirred for 30min to make the system adsorption equilibrium, then add 30μL of H 2 o 2 Solution (30wt%) is irradiated with a xenon lamp light source and starts to react. During the reaction, the temperature is kept at about 30° C., and the complete degradation time of methyl orange is respectively 90min, 60min, 90min ( image 3 ).

Embodiment 3

[0046] In 20ml phenol solution (50mg / L), add 0.4% FeOOH / g-C respectively 3 N 4 , 0.9% FeOOH / g-C 3 N 4 , 2.3% FeOOH / g-C 3 N 4 Catalyst 80mg, after magnetic stirring for 30min, add 30μL of H 2 o 2 (30wt%), irradiate with a xenon lamp light source and start to react, keep the reaction temperature between 30~33°C during the experiment, the gas phase sampling needle collects 500 μ L gas samples each time and injects them into the gas chromatograph (GC-7900) to detect the carbon dioxide concentration . Within 120min, the mineralization rates of phenol were 61%, 74%, 24% ( Figure 4 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com