Neutral room-temperature-vulcanization silicone sealant

A technology for vulcanizing silicone and sealant, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of inability to disperse hard agglomerated particles, increase manufacturing costs, difficulty in dispersing and depolymerizing, and achieve increased Dissolving properties, improving regularity, and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method for modified nano-calcium carbonate, comprising the following steps:

[0031] 1) to saturated Ca(OH) 2 Add chitosan to the slurry, and then put it into the carbonization tower for stirring; the amount of polysaccharide added is saturated Ca(OH) 2 8% by weight of slurry.

[0032] 2) Step 1) treated Ca(OH) 2 The slurry is pumped out and sent to the emulsification disperser, and CO is fed into the emulsification disperser at the same time 2 Gas and Ca(OH) 2 The slurry is mixed and reacted, and the emulsification disperser is emulsified and dispersed, and the mixed slurry is continuously sent back to the carbonization tower to make the Ca(OH) 2 The slurry is continuously circulated between the carbonization tower and the emulsification disperser for carbonization and emulsification dispersion; when the carbonization reaches pH=9, stop CO 2 The introduction of gas and the operation of the emulsification disperser;

[0033] 3) Add acrylic acid emuls...

Embodiment 2

[0037] A preparation method for modified nano-calcium carbonate, comprising the following steps:

[0038] 1) to saturated Ca(OH) 2 Add chitosan in the slurry, then put it into the carbonization tower and carry out stirring process; the addition of chitosan is saturated Ca(OH) 2 10% of the slurry weight.

[0039] 2) Step 1) treated Ca(OH) 2 The slurry is pumped out and sent to the emulsification disperser, and CO is fed into the emulsification disperser at the same time 2 Gas and Ca(OH) 2 The slurry is mixed and reacted, and the emulsification disperser is emulsified and dispersed, and the mixed slurry is continuously sent back to the carbonization tower to make the Ca(OH) 2 The slurry is continuously circulated between the carbonization tower and the emulsification disperser for carbonization and emulsification dispersion; when the carbonization reaches pH=10, stop CO2 The introduction of gas and the operation of the emulsification disperser;

[0040] 3) Add acrylic acid ...

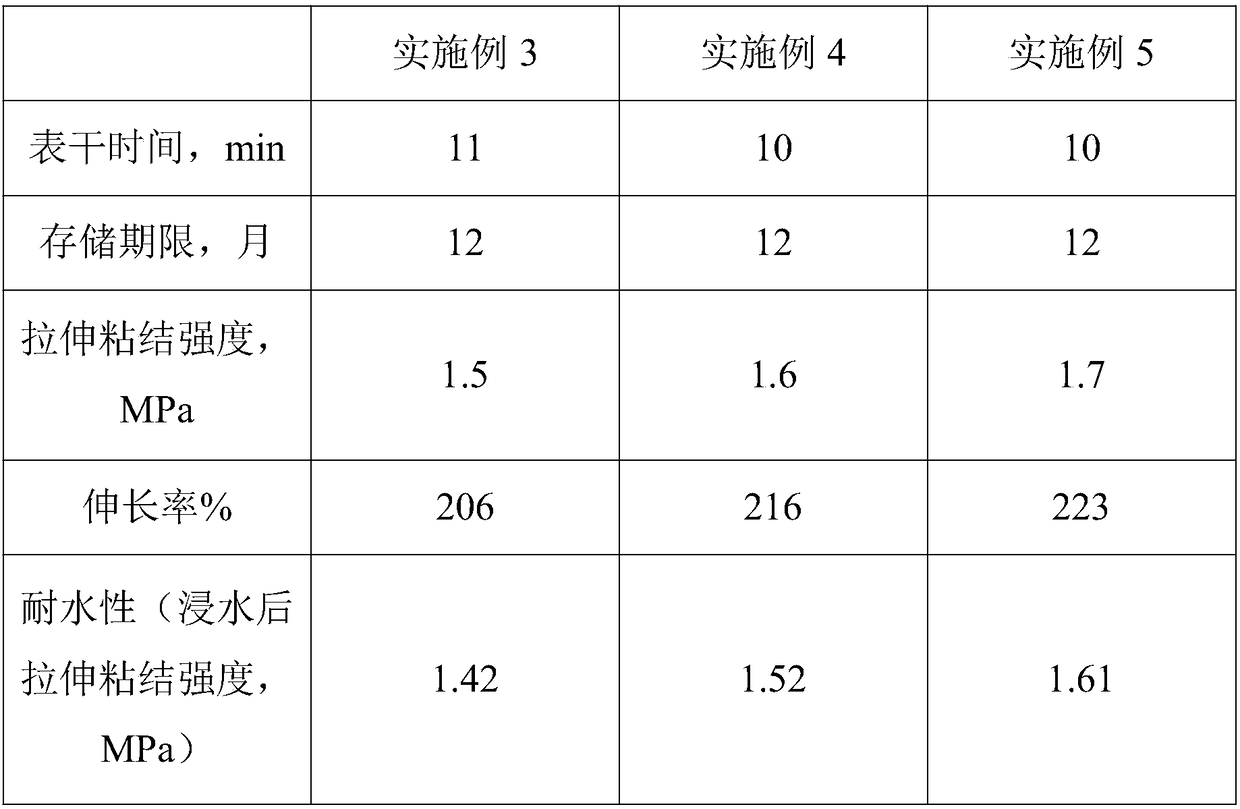

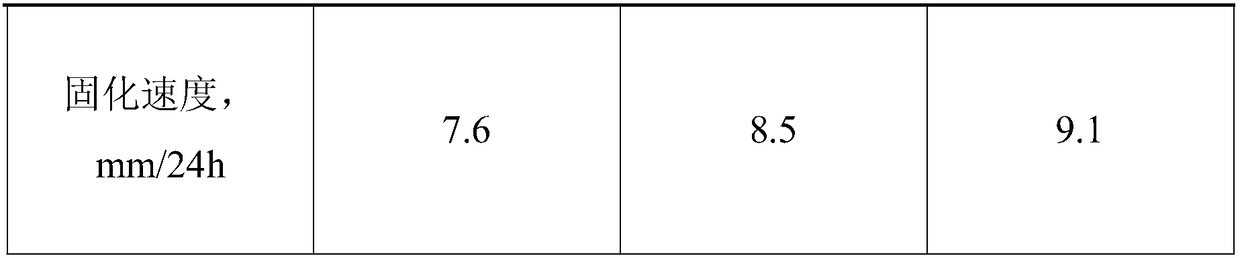

Embodiment 3

[0044] A neutral room temperature vulcanizing silicone sealant, calculated in parts by weight, comprising the following components:

[0045] 50 parts of silane-terminated polydimethylsiloxane, 36 parts of α, ω-dihydroxypolydimethylsiloxane, 85 parts of modified nano-calcium carbonate of Example 1, 8 parts of crosslinking agent, February silicon 3.2 parts of dibutyltin acid and 2.6 parts of γ-(2,3-glycidoxy)propyltrimethoxysilane. The crosslinking agent is a mixture of ethyltris(isoallyloxy)silane and tetrabutanoximinosilane in a mass ratio of 5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com