Chitosan and microorganism compound preparation as well as preparation method and application thereof

A compound preparation, chitosan technology, applied in the direction of drug combination, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of water quality deterioration, environmental and human unsafety, etc., to improve water quality, enhance immunity, Improve the effect of animal gut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing the chitosan-microbial composite preparation of the above technical solution, which includes the following steps:

[0035] A. Anaerobic fermentation of Lactobacillus with MRS liquid medium to obtain Lactobacillus fermentation broth;

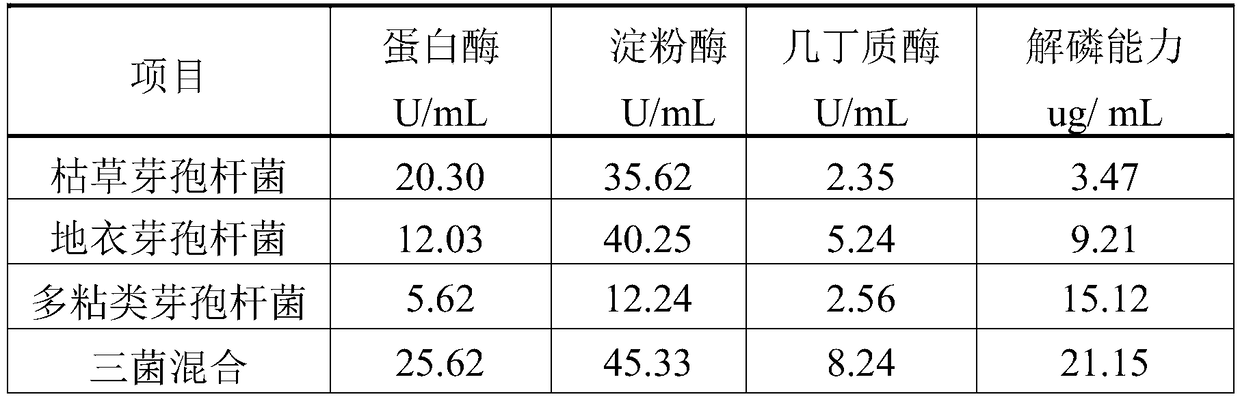

[0036] B. Mixed fermentation of Bacillus subtilis, Bacillus licheniformis and Bacillus polymyxa with the improved beef extract peptone medium to obtain the compound Bacillus fermentation broth;

[0037] In terms of mass percentage, the improved beef extract peptone medium includes beef extract 0.1-0.5%, peptone 0.3-0.8%, sucrose 0.1-0.6%, sodium chloride 0.05-0.4%, dipotassium hydrogen phosphate 0.01-0.05% , Potassium dihydrogen phosphate 0.02~0.08% and the balance of water, pH 6.8~7.2;

[0038] C. Mix the fermentation broth of Lactobacillus, the fermentation broth of Bacillus complex and chitosan, and adjust the pH to 6.8-7.0 to obtain a chitosan microbial composite preparation;

[0039] T...

Embodiment 1

[0054] The MRS liquid medium was prepared, and Lactobacillus (ATCC393) was inoculated into the MRS liquid medium with an inoculum amount of 10%, and anaerobic fermentation was carried out at 26° C. for 90 hours to obtain a fermentation broth of Lactobacillus containing 550 million bacteria / ml.

[0055] Preparation of improved beef extract peptone medium: beef extract 0.3%, peptone 0.5%, sucrose 0.3%, sodium chloride 0.2%, dipotassium hydrogen phosphate 0.03%, potassium dihydrogen phosphate 0.05%, pH 6.8-7.2 and the balance Inoculate Bacillus subtilis (CICC 20445), Bacillus licheniformis (CICC 23584) and Bacillus polymyxa (ATCC 842) with 10% of the inoculum amount, and mix at 27℃ and 20% dissolved oxygen concentration. After 75 hours of fermentation, a complex bacillus fermentation broth with a bacterial content of 520 million cells / ml is obtained.

[0056] After mixing 12 kg of Lactobacillus fermentation broth, 24 kg of complex Bacillus fermentation broth, 35 kg of bran, 20 kg of z...

Embodiment 2

[0059] The MRS liquid medium was prepared, and Lactobacillus (ATCC393) was inoculated into the MRS liquid medium with an inoculum amount of 10%, and anaerobic fermentation was carried out at 31° C. for 90 h to obtain a lactobacillus fermentation broth containing 500 million bacteria / ml.

[0060] Preparation of modified beef extract peptone medium: beef extract 0.3%, peptone 0.5%, sucrose 0.3%, sodium chloride 0.2%, dipotassium hydrogen phosphate 0.03%, potassium dihydrogen phosphate 0.05% and the balance of water, pH 6.8 ~7.2. Bacillus subtilis (CICC 20445), Bacillus licheniformis (CICC 23584) and Bacillus polymyxa (ATCC 842) were respectively inoculated with 10% inoculum, and mixed fermentation was carried out at 31℃ and 45% for 75h to obtain the bacteria-containing The amount of 260 million / ml compound bacillus fermentation broth.

[0061] After mixing 8 kg of Lactobacillus fermentation broth, 32 kg of compound Bacillus fermentation broth, 30 kg of bran, 20 kg of zeolite powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com