Straw cellulose antibacterial fresh-keeping film and preparation method thereof

A technology of straw cellulose and fresh-keeping film, which is applied in the field of fresh-keeping, can solve problems affecting food safety and sanitation, poor air flow, high environmental humidity, etc., and achieve good mechanical properties, simple process, and the effect of environmental degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

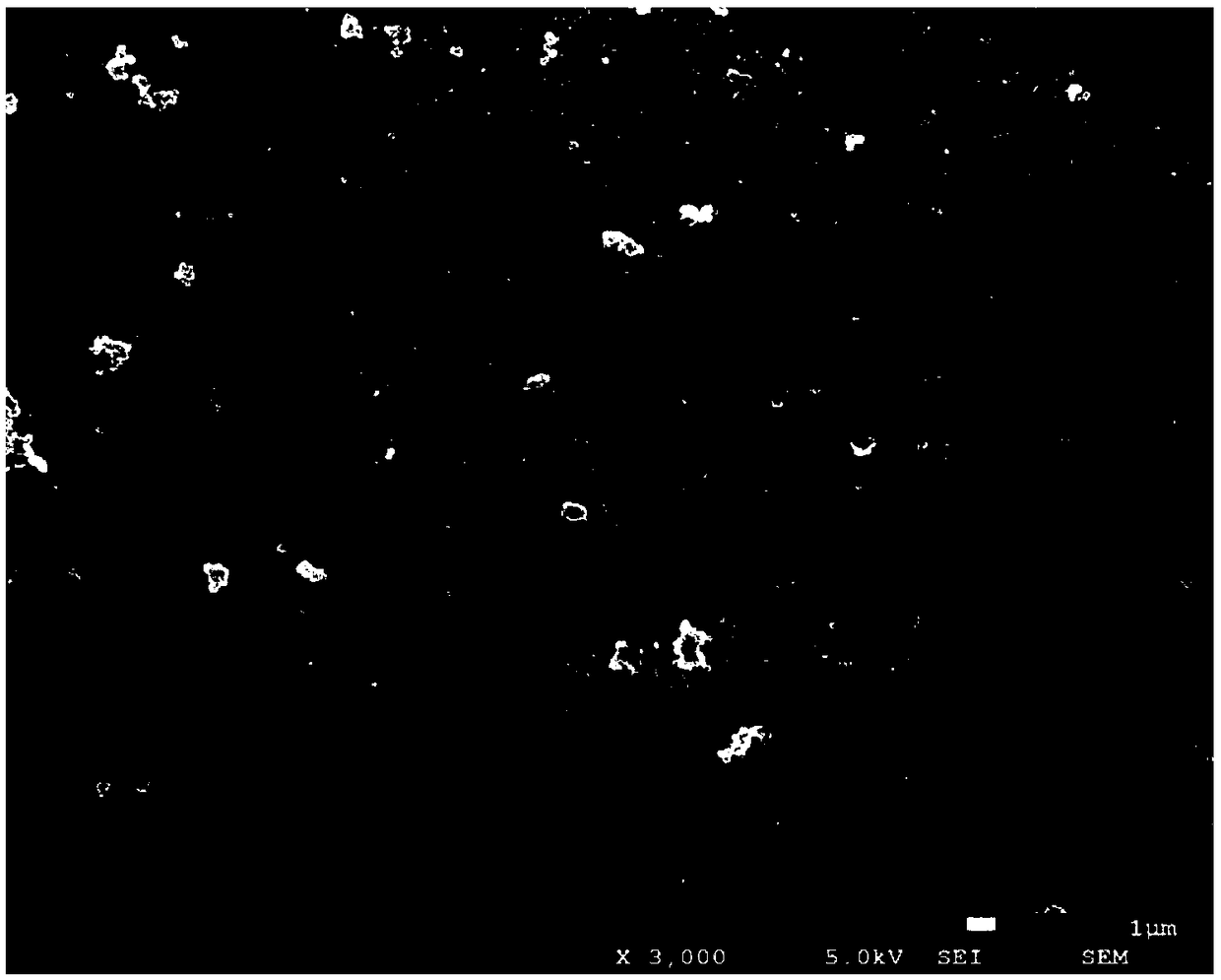

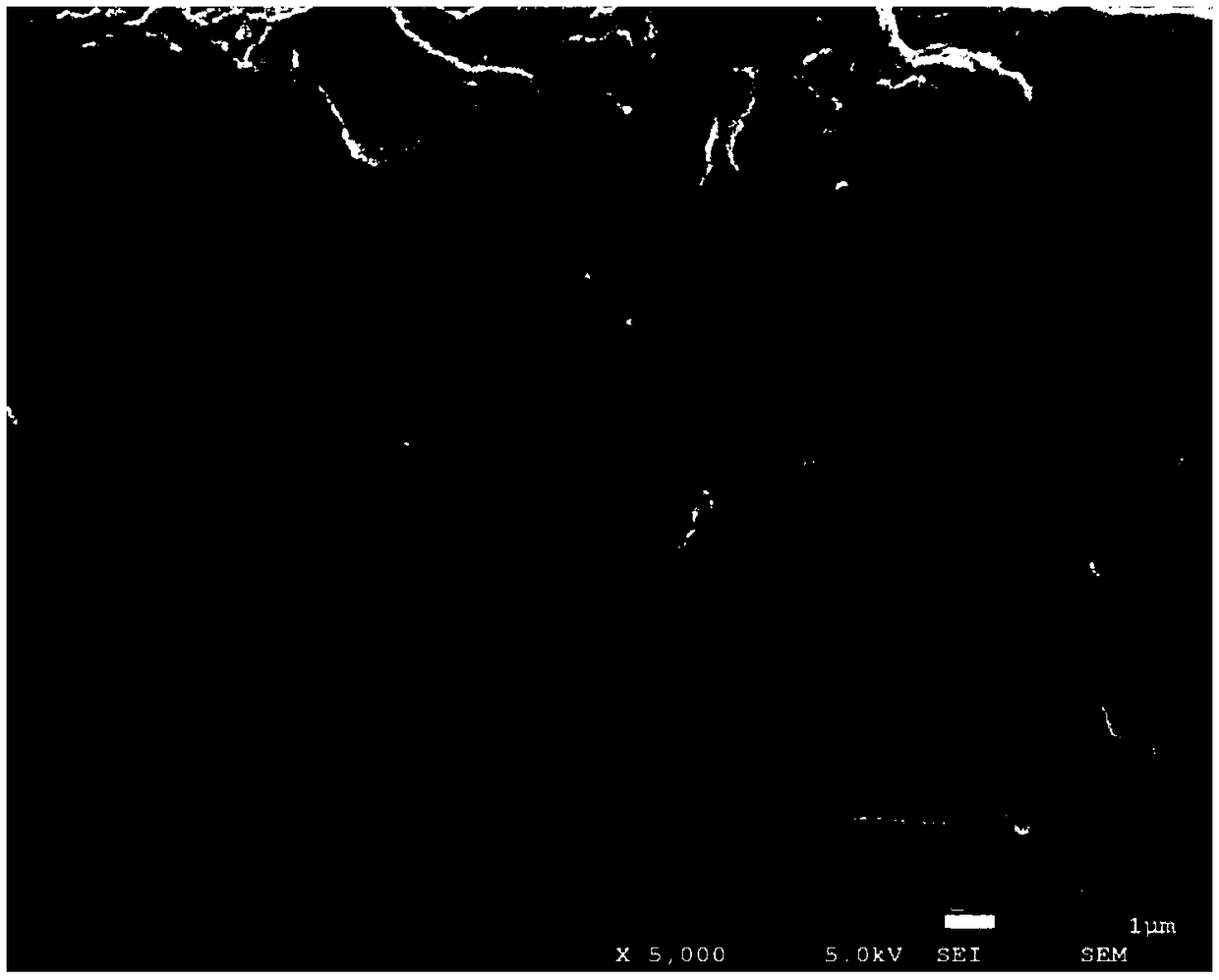

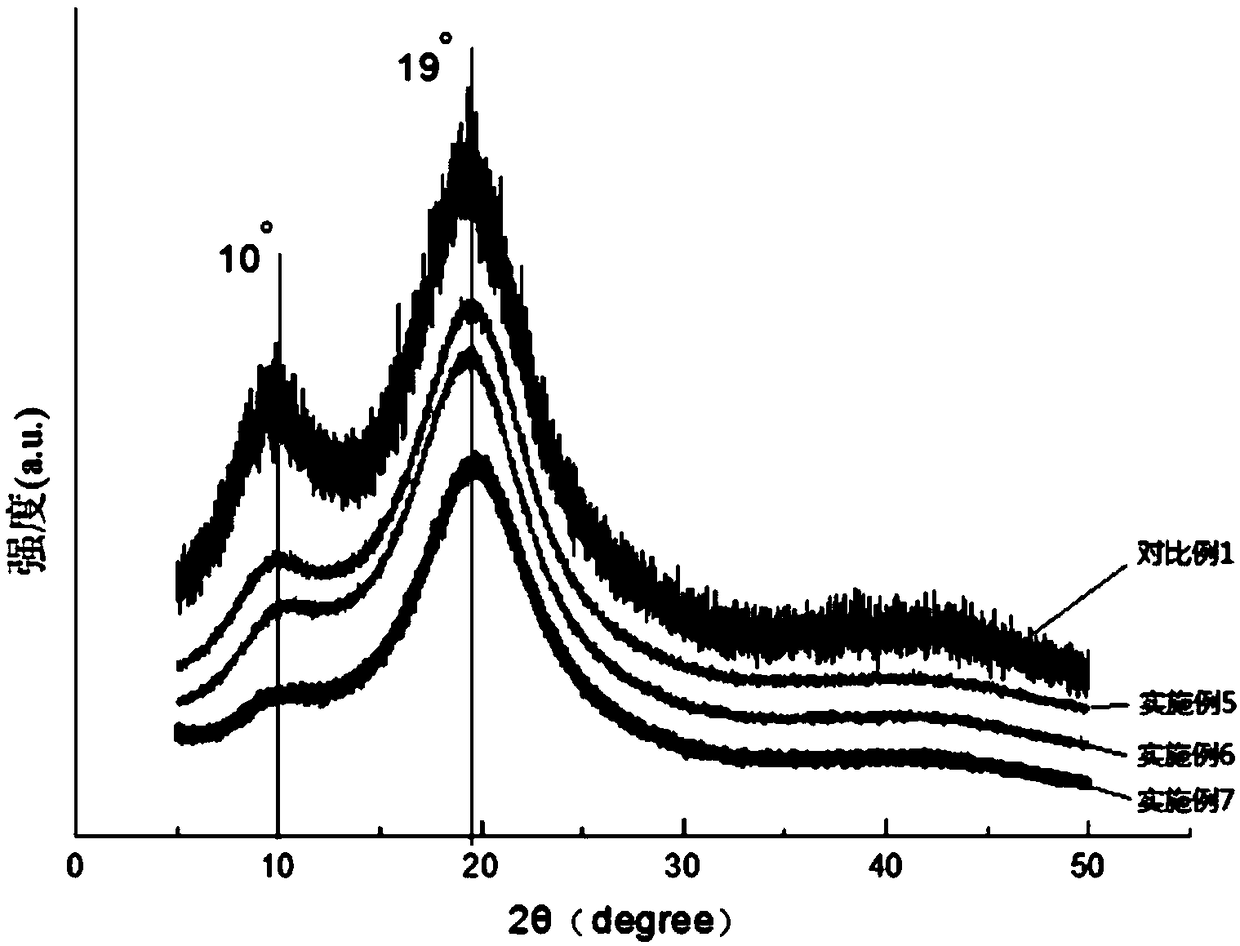

Image

Examples

Embodiment 1

[0046] A straw cellulose antibacterial fresh-keeping film prepared from microcrystalline cellulose obtained from plant straws, the antibacterial fresh-keeping film contains a certain quality of antibacterial agent, and the antibacterial agent is dandelion extract or tea polyphenol one or a combination of two.

Embodiment 2

[0048] A straw cellulose antibacterial fresh-keeping film is prepared from microcrystalline cellulose obtained from plant straws, and the antibacterial fresh-keeping film contains an antibacterial agent with a mass of 10-30% of the raw material microcrystalline cellulose, and the antibacterial agent is One or a combination of dandelion extract or tea polyphenols.

Embodiment 3

[0050] A preparation method of straw cellulose antibacterial fresh-keeping film, the steps are as follows:

[0051] Step 1, preparing straw cellulose:

[0052] Remove the leaves of the plant straw, cut into sections, wash and heat-treat in boiling water for 1 hour, dry and crush the heat-treated straw to 40 meshes to obtain straw powder; mix the straw powder with NaOH solution according to a certain solid-liquid ratio and mix under certain conditions Complete the alkalization treatment, after centrifugation, wash the first centrifugal sediment to neutrality and mix it with sodium chlorite solution according to a certain solid-liquid ratio, adjust the pH to 4.0, complete the decolorization and impurity removal treatment at a certain temperature and centrifuge, and the second The centrifuged sediment was washed to neutrality and dried and pulverized to obtain straw cellulose;

[0053] Step 2, preparing microcrystalline cellulose:

[0054] mixing the straw cellulose obtained in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com