Synthesis method of small-crystal-grain FER (Ferrierite) molecular sieve with laminar stacking structure

A synthesis method and molecular sieve technology, applied in the field of catalysis, can solve problems such as the agglomeration and growth of molecular sieve grains, and achieve the effects of improving surface morphology, enriching pore structure, and improving catalytic activity and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The experimental procedure is as follows: under stirring conditions, 11.6g of alkaline silica sol, 0.175g of NaOH and 0.825g of NaAlO 2 Dissolve in 32.5mL of deionized water and mix evenly, then slowly drop into 5.10mL of ethylenediamine, stir for 1.0h and let it stand, move the obtained mixture into a polytetrafluoroethylene hydrothermal reaction kettle and seal it well, and homogeneously mix at 80°C The reactor was dynamically rotated and aged for 3 hours to form a gel; then the obtained gel was heated to 190°C for dynamic crystallization for 4 hours, and the motor rotation speed was 150rpm; after the crystallization was completed, the reactor was naturally cooled to room temperature, and the obtained solid was filtered The product was washed 3-5 times with deionized water and absolute ethanol to remove part of the Na + and template agent, and then placed in a drying oven to dry at 120°C for 6h. Move the dried molecular sieve product into a dielectric barrier dischar...

Embodiment 2

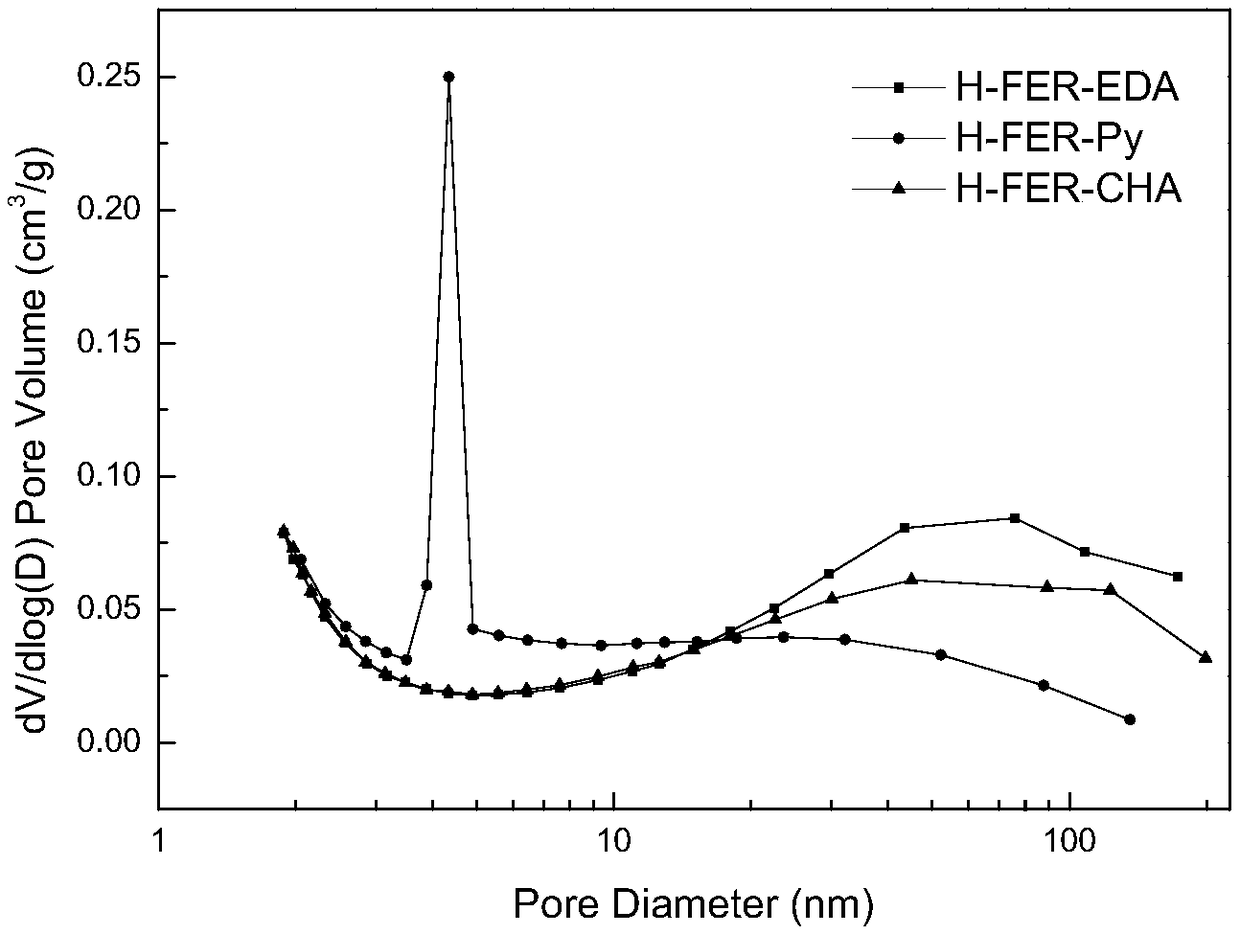

[0032] Molecular sieve preparation Referring to Example 1, 5.10 mL of ethylenediamine was replaced with 6.30 mL of pyrrolidine; the rest of the conditions were the same to prepare H-FER-Py molecular sieve. figure 1 b is the SEM image of H-FER-Py molecular sieve, the sheet thickness of the molecular sieve is 40-48nm, and the pore size distribution curve is shown in figure 2 . The evaluation conditions are the same as in Example 1, and the evaluation results are shown in Table 1.

Embodiment 3

[0034] Molecular sieve preparation Referring to Example 1, 5.10 mL of ethylenediamine was replaced with 8.75 mL of cyclohexylamine; the rest of the conditions were the same to prepare H-FER-CHA molecular sieve. figure 1 c is the SEM topography of H-FER-CHA molecular sieve, the sheet thickness of the molecular sieve is 35-65nm, and the pore size distribution curve is shown in figure 2 . The evaluation conditions are the same as in Example 1, and the evaluation results are shown in Table 1.

[0035] Table 1 Performance of FER molecular sieves synthesized by different templates to catalyze n-butene isomerization a

[0036]

[0037] a Test result of continuous reaction for 10h

[0038] Additionally, from figure 2 It can be seen from the shown pore size distribution curve that the H-FER-Py molecular sieve synthesized with Py as the template has obvious mesopore distribution in the range of 4-5nm and 20-40nm, while the H-FER-Py molecular sieve synthesized with EDA and CHA as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com