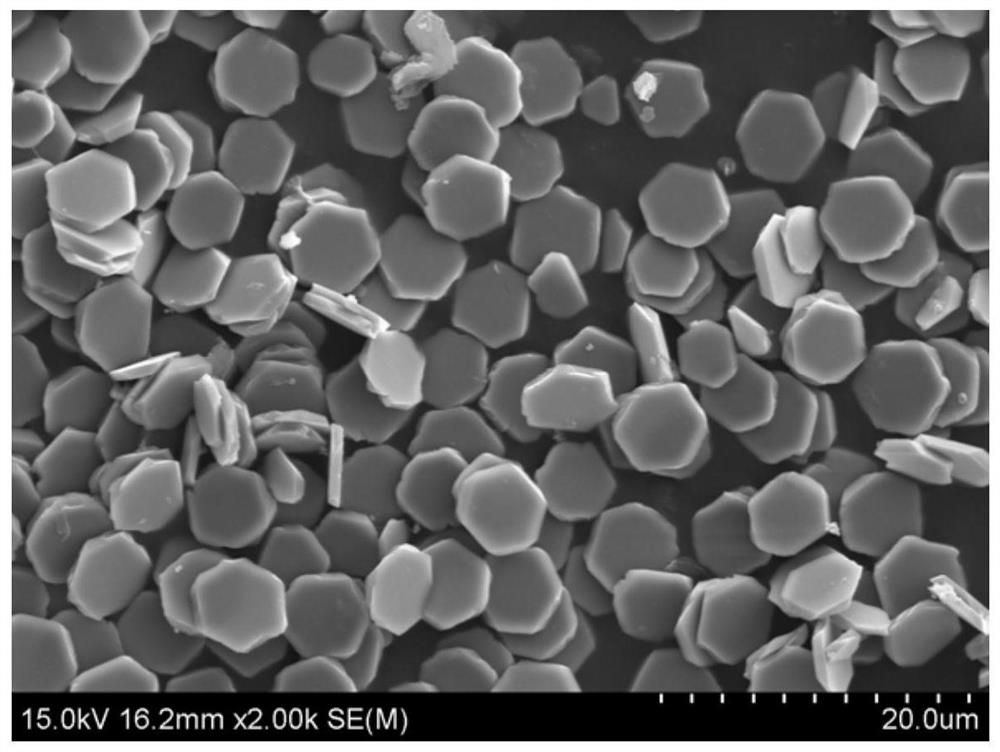

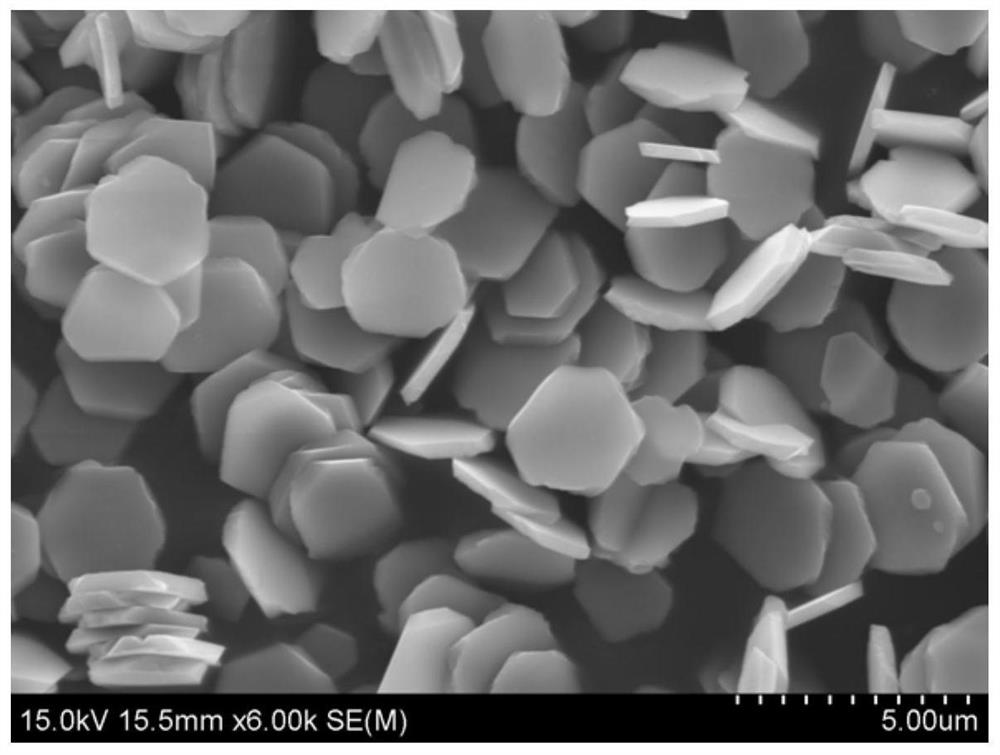

A preparation method of monodisperse micron-sized hexagonal iron oxide flakes

A technology of iron oxide sheet and micron scale, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., to achieve the effect of simple preparation steps, uniform size and shape, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 0.5g of ferric chloride hexahydrate and add it into 38ml of methanol, stir under magnetic stirring until it is completely dissolved, then weigh 1g of polyvinylpyrrolidone and add it, and continue stirring until it is completely dissolved. Another 0.5g of sodium hydroxide was weighed and added into 15mL of water, and magnetically stirred until completely dissolved. The aqueous solution of sodium hydroxide was added dropwise into the methanol solution of ferric chloride hexahydrate prepared above under stirring. Then the above liquid was transferred to a polytetrafluoroethylene-lined reactor, reacted at 160° C. for 16 hours, and cooled naturally at room temperature. Pour the reaction product into a centrifuge tube, wash it with deionized water and methanol for 4 times, then put it in an oven at 55°C for 24 hours to dry, and then put it in a muffle furnace at 500°C for 2 hours to obtain micron-sized particles. Reddish-brown regular hexagonal iron oxide flakes.

Embodiment 2

[0023] Weigh 0.6g of ferric chloride hexahydrate and add it into 45ml of methanol, stir under magnetic stirring until it is completely dissolved, then weigh 0.8g of polyvinylpyrrolidone and add it, and continue stirring until it is completely dissolved. Another 0.6g of sodium hydroxide was weighed and added into 18mL of water, and magnetically stirred until completely dissolved. The aqueous solution of sodium hydroxide was added dropwise into the methanol solution of ferric chloride hexahydrate prepared above under stirring. Then the above liquid was transferred to a Teflon-lined reactor, reacted at 170° C. for 10 hours, and cooled naturally at room temperature. Pour the reaction product into a centrifuge tube, wash with deionized water and methanol for 5 times, then put it in an oven at 60°C for 12 hours to dry, and then put it in a muffle furnace at 480°C for 2 hours to obtain micron-sized particles. Reddish-brown regular hexagonal iron oxide flakes.

Embodiment 3

[0025] Weigh 0.5g of ferric chloride hexahydrate and add it into 52ml of methanol, stir under magnetic stirring until it is completely dissolved, then weigh 1g of polyvinylpyrrolidone and add it, and continue stirring until it is completely dissolved. Another 0.5g of sodium hydroxide was weighed and added into 15mL of water, and magnetically stirred until completely dissolved. The aqueous solution of sodium hydroxide was added dropwise into the methanol solution of ferric chloride hexahydrate prepared above under stirring. Then the above liquid was transferred to a polytetrafluoroethylene-lined reactor, reacted at 180° C. for 16 hours, and cooled naturally at room temperature. Pour the reaction product into a centrifuge tube, wash it with deionized water and methanol for 4 times, then put it in an oven at 55°C for 24 hours to dry, and then put it in a muffle furnace at 550°C for 2 hours to obtain micron-sized particles. Reddish-brown regular hexagonal iron oxide flakes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com